Gear transmission system with convenient adjustment and good using capacity

A gear transmission and gear technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of gear tension limit, no anti-corrosion effect, etc., to avoid loosening, prevent falling off, and avoid oil pollution splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

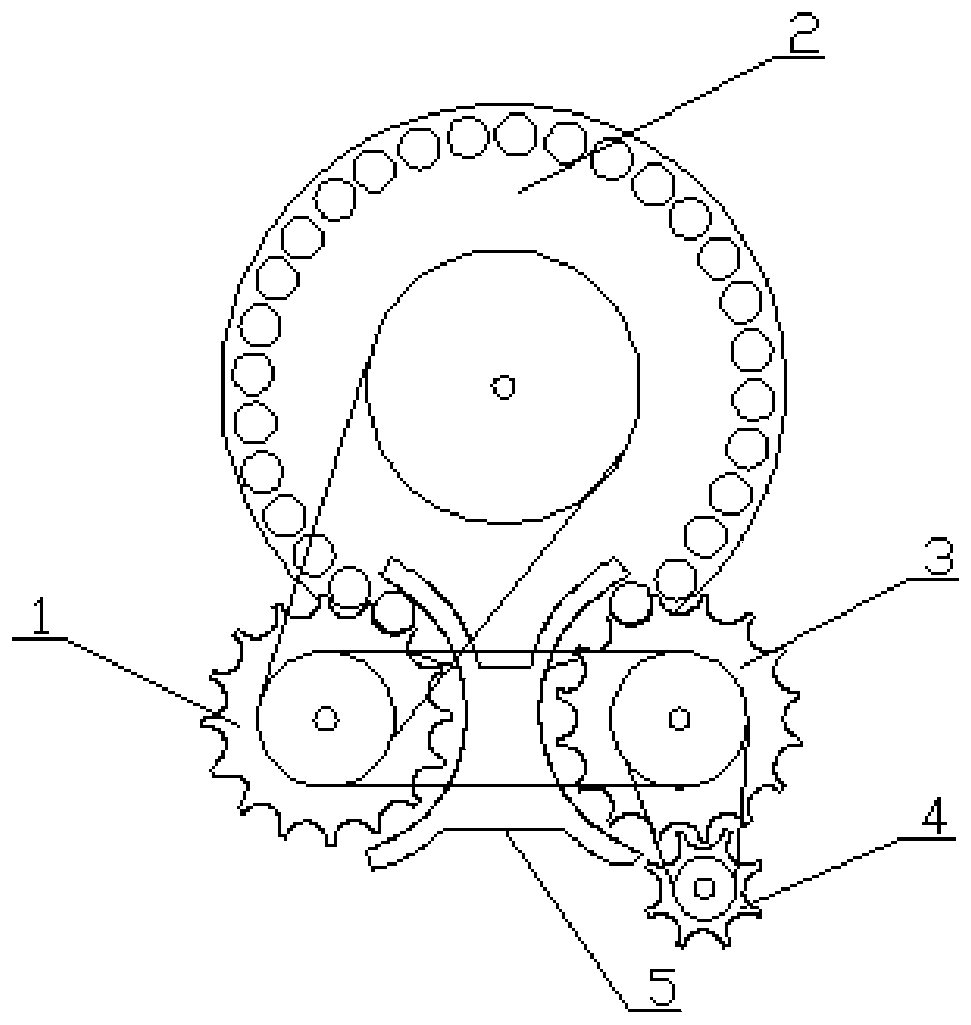

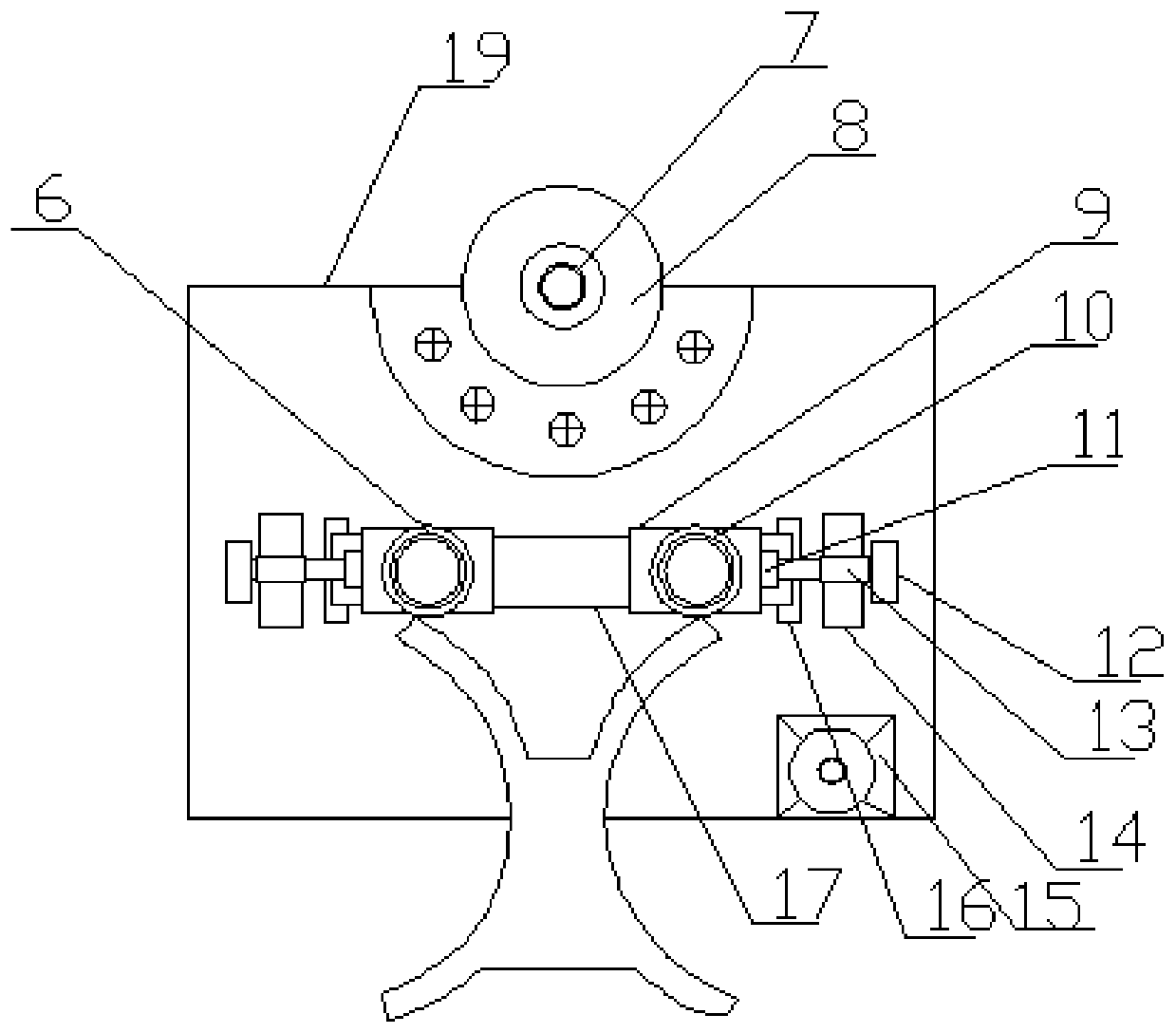

[0023] like Figure 1-3 As shown, a gear transmission system with good usability that is easy to adjust includes an installation side plate 19, a driving motor 15 and an arc-shaped shielding block 5, and the top end of the installation side plate 19 is installed with a second shaft through a limit piece 8 Sleeve 7, the lower end of the No. 2 shaft sleeve 7 is welded with a pad 16, the top of the pad 16 is equipped with a sliding groove 17 through a bolt, and the two ends of the sliding groove 17 are provided with a sliding block 9, and the sliding A No. 3 shaft sleeve 10 and a No. 1 shaft sleeve 6 are respectively installed on the block 9 through bolts. One end of the sliding block 9 is embedded with a bearing 11, and the two ends of the sliding groove 17 are welded with opposite pull blocks 14. The pull block 14 is provided with a threaded sleeve 13, and the bottom end side of the installation side plate 19 is equipped with an active motor 15 through bolts, and the output sha...

Embodiment 2

[0033] like Figure 1-3 As shown, a gear transmission system with good usability that is easy to adjust includes an installation side plate 19, a driving motor 15 and an arc-shaped shielding block 5, and the top end of the installation side plate 19 is installed with a second shaft through a limit piece 8 Sleeve 7, the lower end of the No. 2 shaft sleeve 7 is welded with a pad 16, the top of the pad 16 is equipped with a sliding groove 17 through a bolt, and the two ends of the sliding groove 17 are provided with a sliding block 9, and the sliding A No. 3 shaft sleeve 10 and a No. 1 shaft sleeve 6 are respectively installed on the block 9 through bolts. One end of the sliding block 9 is embedded with a bearing 11, and the two ends of the sliding groove 17 are welded with opposite pull blocks 14. The pull block 14 is provided with a threaded sleeve 13, and the bottom end side of the installation side plate 19 is equipped with an active motor 15 through bolts, and the output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com