Automatic firing calibration system and calibration method based on thermal imaging telescopic sight

A calibration method and calibration system technology, which is applied in the field of infrared thermal imaging sights, can solve the problems of unreliable accuracy, low efficiency of the shooting effect calibration system, and poor universality, so as to reduce the difficulty of operation, reduce the time for gun calibration, and meet professional requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

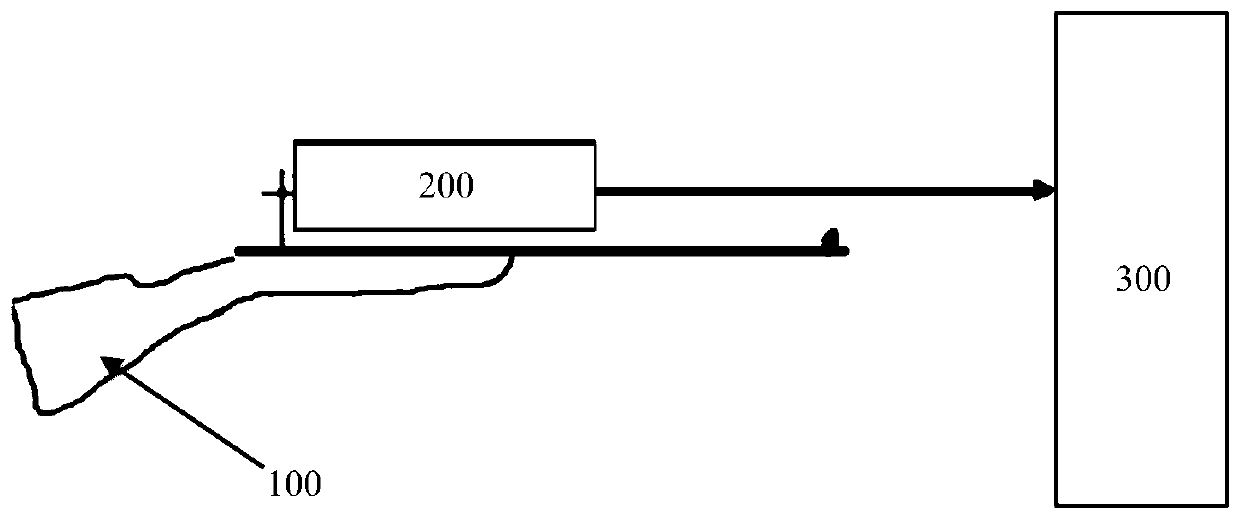

[0044] For the structural schematic diagram of the automatic firing effect correction system based on the thermal imaging sight in this embodiment, please refer to the appendix figure 1 .

[0045] An automatic firing effect correction system based on a thermal imaging sight, comprising a firearm 100, a thermal imaging sight 200 and a thermal target 300, the thermal imaging sight 200 is fixedly mounted on the firearm 100, and the thermal target 300 is mounted on a target at a set distance On the track, target information used to generate specific features for targeting using the thermal imaging sight 200 .

[0046] The thermal imaging sight 200 includes an accelerometer sensor (not shown), which can be used to determine whether the gun has been aimed and stabilized, whether the bullet has been fired, whether it has been fired and stabilized, and the like.

[0047] The thermal imaging sight 200 also includes a processor and a memory, which can acquire and store images in real t...

Embodiment 2

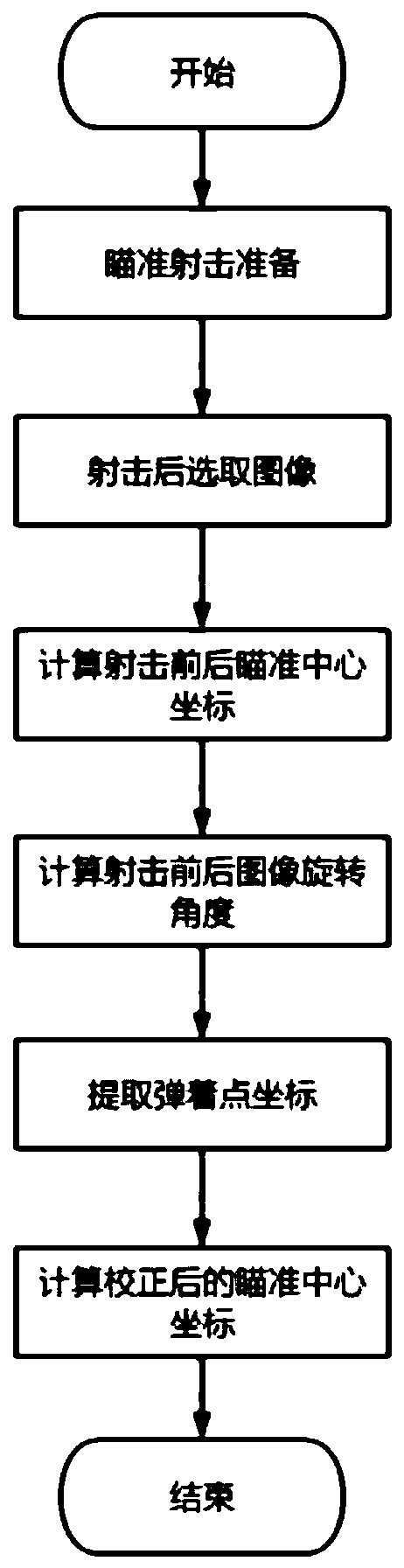

[0049] For the automatic firing effect correction method based on the thermal imaging sight in this embodiment, please refer to the appendix Figure 2-5 .

[0050] An automatic firing effect correction method based on a thermal imaging sight, comprising the following steps:

[0051] Step S100, prepare for aiming and shooting.

[0052] After the user aims at the target, the thermal imaging sight 200 continuously takes pictures of the thermal target 300, and collects the value of the accelerometer corresponding to each frame of the image. When the value of the accelerometer is lower than the first set threshold for a certain period of time and / or when the difference between the image frames is less than the second set threshold, it is assumed that the gun is basically stable, and the system prompts the user whether the target has been aimed. Then the user is prompted to perform the shooting action.

[0053] Step S200, selecting an image after shooting.

[0054] When the fire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com