Patrol point inspection task execution and route optimization method based on historical data

A technology of historical data and optimization methods, applied in the fields of maintenance and equipment operation, can solve the problems of difficulty in improving the efficiency of patrol inspection, unscientific route planning, and inability to solve problems well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

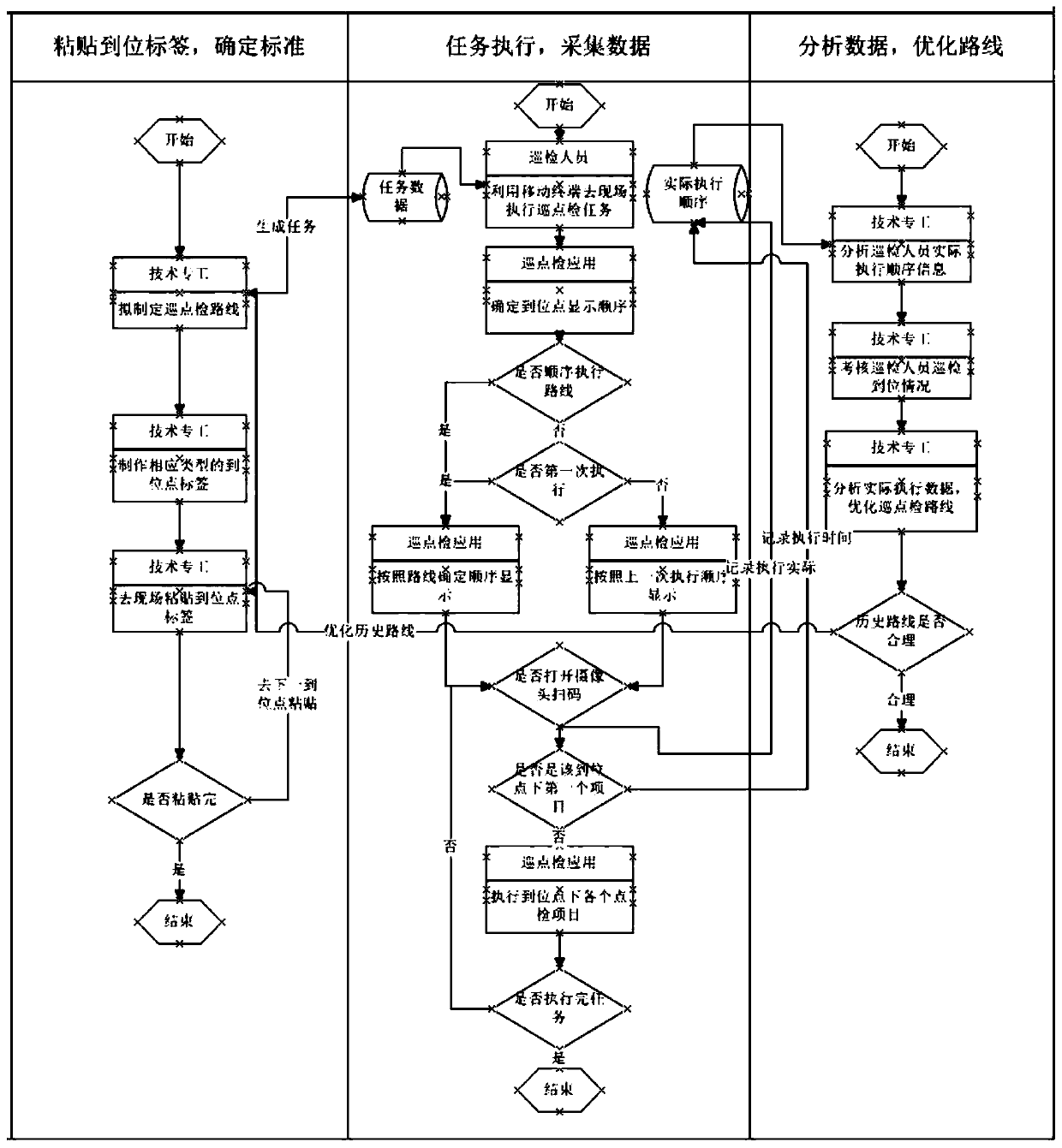

[0042] Such as figure 1 as shown,

[0043] A method for executing inspection tasks and optimizing routes based on historical data, comprising the following steps:

[0044] Step S1: According to the historical patrol inspection situation, the technical specialist plans to formulate the patrol inspection route and produce task data;

[0045] Step S2: Paste the location label according to the inspection route to complete the setting of the check-in location;

[0046] Step S3: Determine the display order of each inspection site on the inspection APP;

[0047] Step S4: Execute the patrol inspection task, and record the execution sequence information, that is, collect the actual execution sequence information;

[0048] Step S5: Analyzing the recorded execution sequence information data to optimize the inspection route.

[0049] Further, the step S2 further includes the following steps:

[0050] Step S21: According to the patrol inspection route, the technical specialist makes t...

Embodiment 2

[0073] Such as figure 1 as shown,

[0074] A method for performing inspection tasks and optimizing routes based on historical data, including:

[0075] Step 1. Make a route

[0076] The inspection route will be formulated by technical specialists according to the historical inspection situation.

[0077] Step 2. Paste the label in place

[0078] The technical specialist goes to the job site and pastes the prepared in-place label to the corresponding in-place point.

[0079] Step 3. Determine the display order of each patrol inspection point on the patrol inspection APP

[0080] The inspection personnel perform the corresponding inspection tasks, and first judge whether the current inspection route is a route that must be executed sequentially. The task to be executed will then judge whether the current route is executed for the first time. If it is the first time to execute, each inspection area will be displayed on the patrol inspection APP in the order specified by the ...

Embodiment 3

[0086] Such as figure 1 as shown,

[0087] A patrol inspection task execution and route optimization method based on historical data, which is divided into three parts: paste the patrol inspection route to the site label, execute the corresponding patrol inspection task to obtain specific task execution sequence information, and analyze the task execution sequence Information assessment patrol inspection task execution and optimize route setting. In actual work, it is a process of continuous optimization.

[0088] 1. Paste to the site label according to the inspection route

[0089] In the early stage of project implementation, according to the historical inspection situation, it is planned to formulate relevant inspection routes, and generate corresponding arrival point labels, and paste the labels to relevant locations on the site to complete the check-in location setting.

[0090] 2. Execute corresponding patrol inspection tasks to collect actual execution sequence infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com