Aviation oven control sensor positioning method and device, equipment and medium

A positioning method and sensor technology, applied in the direction of instruments, design optimization/simulation, image data processing, etc., can solve the problems of low accuracy and efficiency, and achieve the effects of improving efficiency, determining accurate positions, and ensuring authenticity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

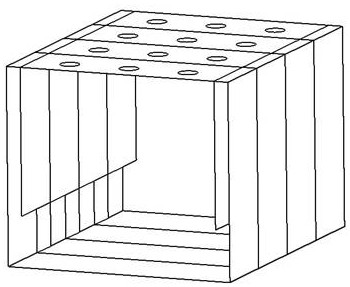

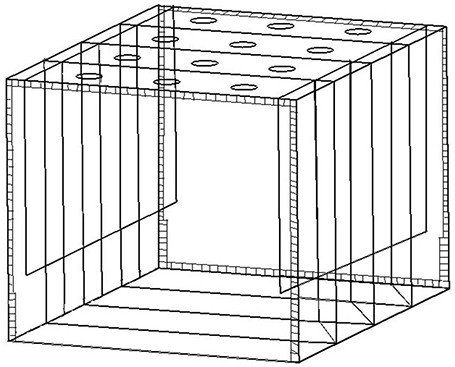

[0049] refer to Figure 1-Figure 4 , the present embodiment provides an aviation oven control sensor positioning method, comprising the following steps:

[0050] extracting the geometric features of the oven, and constructing a three-dimensional geometric model of the oven according to the geometric features;

[0051]Importing the three-dimensional geometric model into simulation software, and inputting material parameters of the oven, and dividing the three-dimensional geometric model of the oven into meshes according to the material parameters;

[0052] Simplify the heat exchange mode of the oven after grid division, and determine the parameters of the hot air flow;

[0053] Taking the parameters of the thermal flow as boundary conditions and inputting them into the simulation software;

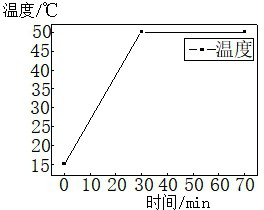

[0054] Input the preset heating condition according to the actual production situation; wherein, the heating condition is to heat up first and then keep warm;

[0055] Obtain the tempera...

Embodiment 2

[0078] refer to Figure 1-Figure 4 , this embodiment provides an aviation oven control sensor positioning device based on Embodiment 1, including:

[0079] A model building module, configured to extract geometric features of the oven, and construct a three-dimensional geometric model of the oven according to the geometric features;

[0080] A grid division module, configured to import the three-dimensional geometric model into simulation software, and input material parameters of the oven, and perform grid division on the three-dimensional geometric model of the oven according to the material parameters;

[0081] The parameter determination module is used to simplify the heat exchange mode of the oven after grid division, and determine the parameters of the hot air flow;

[0082] The boundary condition input module is used to use the parameters of the thermal flow as boundary conditions and input them into the simulation software;

[0083] The heating condition input module ...

Embodiment 3

[0088] This embodiment provides a computer device based on Embodiment 1. The computer device includes a memory and a processor, where a computer program is stored in the memory, and the processor executes the computer program to implement the method described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com