Method and system for determining segmented modeling points for temperature-sensitive intervals

A segmented modeling and segmented point technology, applied in general control systems, control/regulation systems, simulators, etc., can solve problems such as reducing model prediction accuracy and prediction robustness, model prediction performance fluctuations, and prediction performance fluctuations. The effect of easy promotion, cost reduction, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

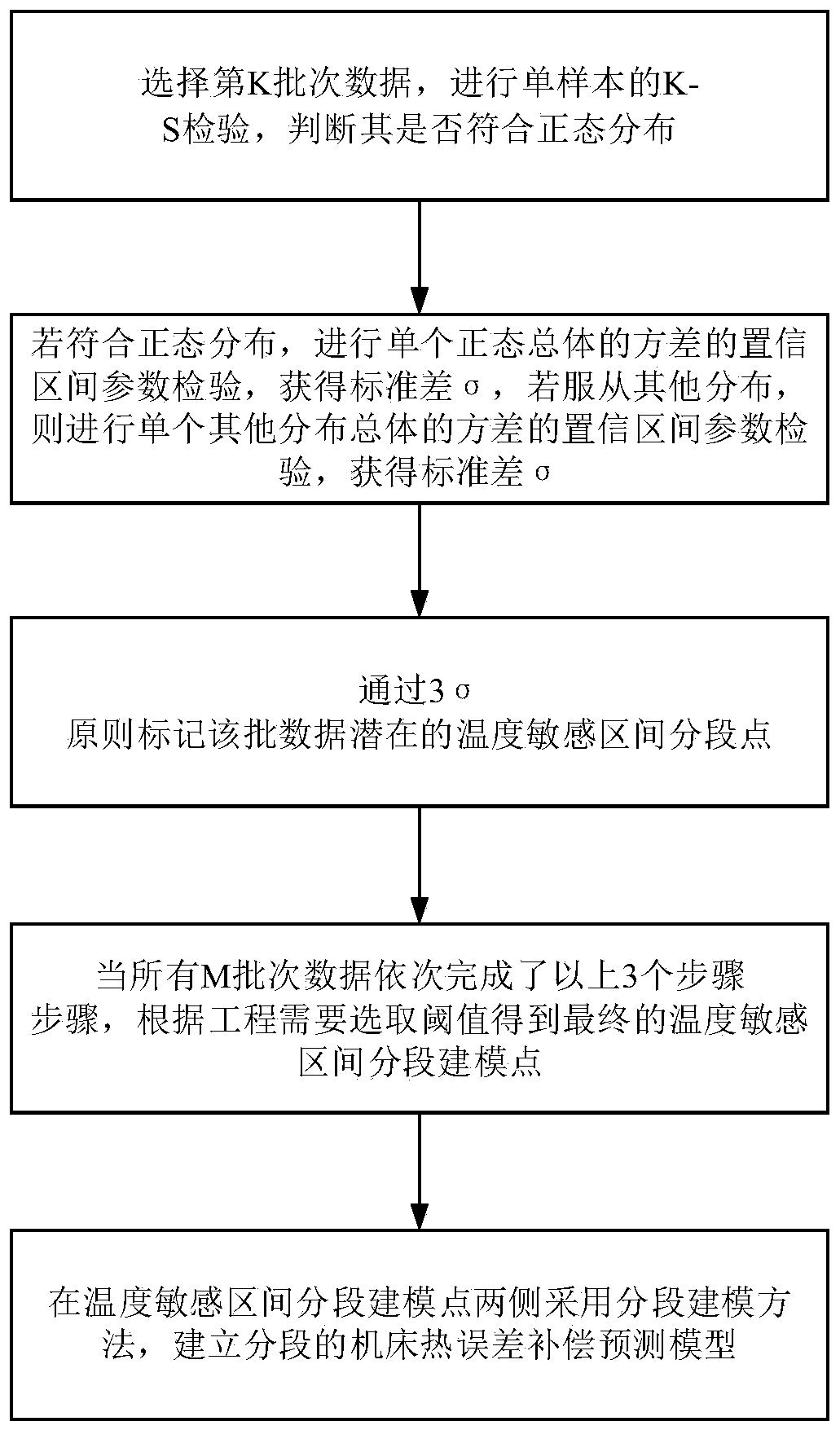

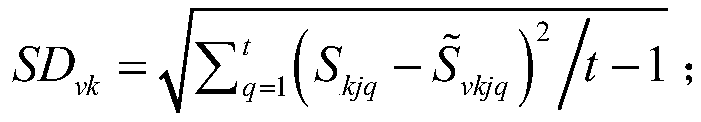

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

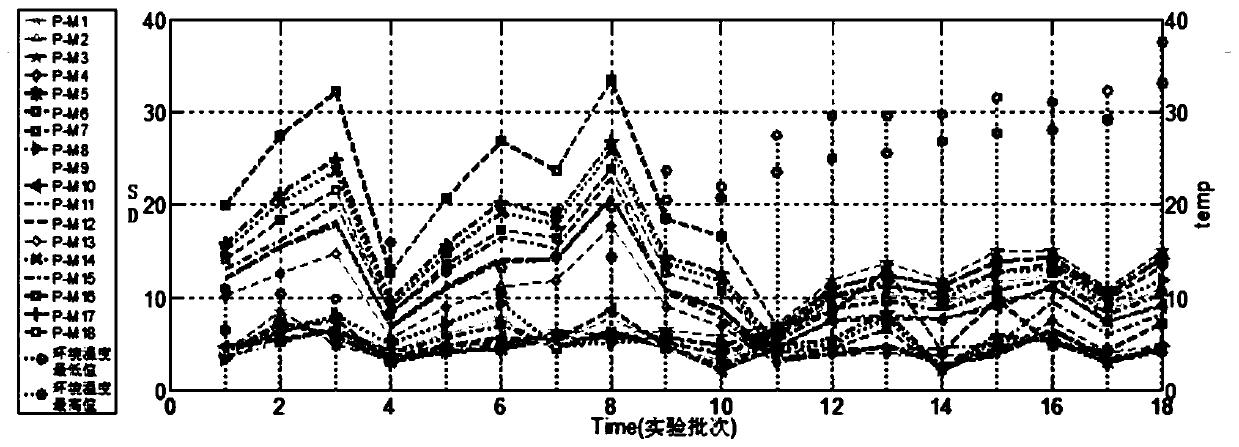

[0030] 1. Data collection

[0031] The data acquisition system includes an infrared thermal imager, a temperature sensor group and an eddy current displacement sensor;

[0032] Infrared thermal imager is used to make a thermal image of the machine tool to obtain the temperature color image characteristics of the machine tool; according to the temperature color image characteristics displayed by the thermal imager, the heat source area of the machine tool can be manually marked;

[0033] The temperature sensor group is set separately at the heat source area of the manual marking machine tool and the environment where the machine tool is arranged; wherein, the temperature sensor set at the main heat source area (spindle, motor, screw bearing, etc.) of the manual marking machine tool is used To collect the temperature of the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com