Wireless charging magnetic core for vehicle-mounted power supply

A wireless charging and vehicle-mounted power supply technology, applied in electric vehicle charging technology, transformer/inductor magnetic core, charging station, etc., can solve the problems of performance impact, rapid temperature rise, reduced charging efficiency, etc., to improve heat dissipation and interior space. , Improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

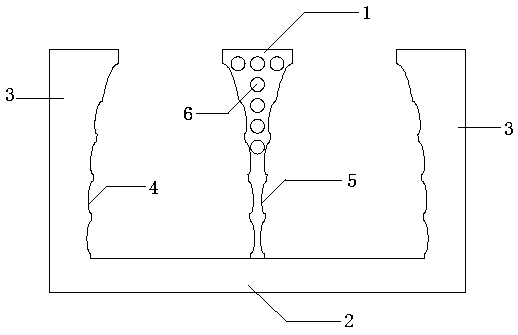

[0021] Such as figure 1 Shown is a schematic diagram of the structure of the heat dissipation column in the present invention when the waist-shaped column is selected. The present invention is a magnetic core for wireless charging used in a vehicle power supply, including a magnetic core body and a heat dissipation column 1 installed in the middle of the magnetic core body; The magnetic core body includes a magnetic core base 2 combined into a semi-open whole and magnetic core legs 3 located on both sides; the inner surface of the magnetic core leg 3 is set as a leg spherical surface; the heat dissipation column 1 is vertically arranged on the magnetic base 2 In the middle of the surface, there are heat dissipation spherical surfaces corresponding to the spherical surfaces of the legs on both sides.

[0022] The heat dissipation column 1 is a waist-shaped column, and heat dissipation channels 6 are evenly distributed in the heat dissipation column 1. Both sides of the heat dis...

Embodiment 2

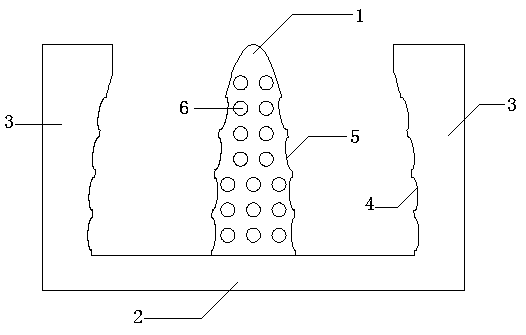

[0024] Such as figure 2 As shown, the main structure of this embodiment is the same as that of Embodiment 1, the difference is that: the heat dissipation column 1 is hemispherical; the spherical surface of the outrigger and the heat dissipation column have the same spherical center; Outrigger drainage grooves 4 and heat dissipation drainage grooves 5; outrigger drainage grooves 4 and heat dissipation drainage grooves 5 are arranged alternately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com