Thermal management components for battery modules, battery modules and vehicles

A battery module and thermal management technology, applied in electrical components, secondary batteries, circuits, etc., can solve problems such as large temperature difference between upper and lower sides, and achieve the effects of rapid heat conduction, high reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The making and using of the embodiments are discussed in detail below. It should be understood, however, that the specific embodiments discussed are merely illustrative of specific ways to make and use the invention and do not limit the scope of the invention.

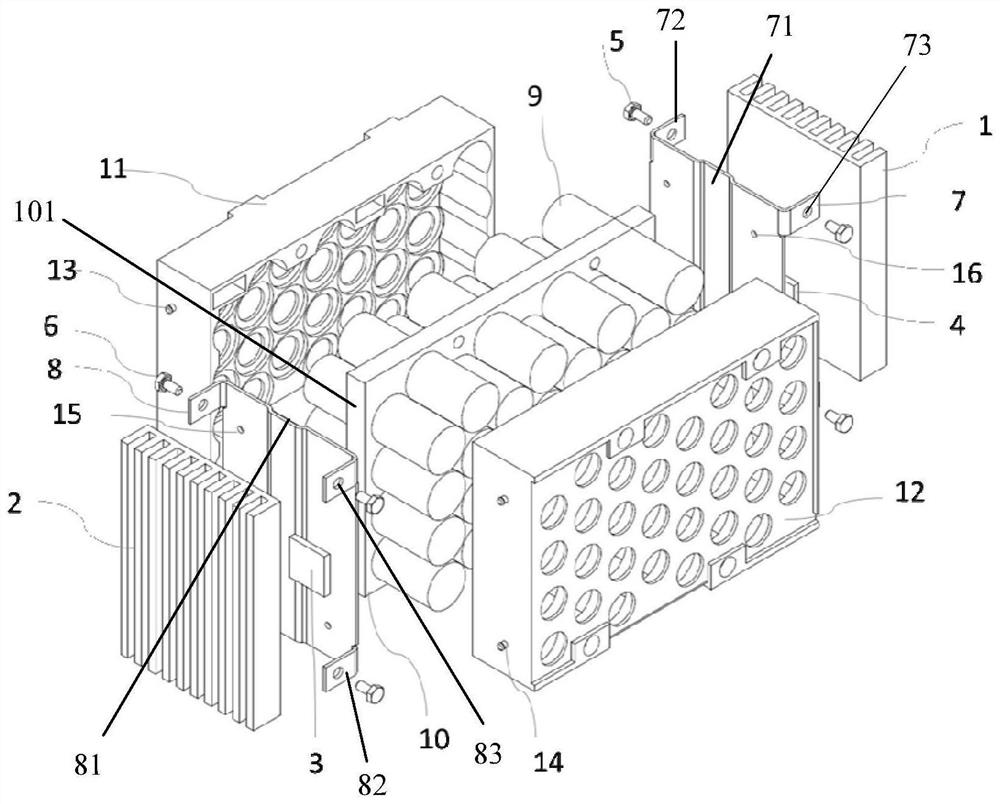

[0025] In order to better demonstrate the internal structure of the battery module and its thermal management assembly according to the present invention, a preferred embodiment of this battery module is by means of figure 1 The exploded schematic diagram is shown. figure 1 It is not only used for explaining the present invention, but also helps to define the present invention when necessary.

[0026] refer to figure 1 , The battery module according to the present invention includes a battery pack, a first casing 11 , a second casing 12 and at least one thermal management component.

[0027] The battery pack is composed of multiple rows of cells (for example, cylindrical cells) 9, wherein the arrangement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com