Novel hexafluoropropylene cracking temperature control system

A technology of temperature control system and hexafluoropropylene, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of inaccurate temperature control, high power consumption of cracking furnace temperature control system, etc., and achieve temperature control accuracy High efficiency, obvious energy saving and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

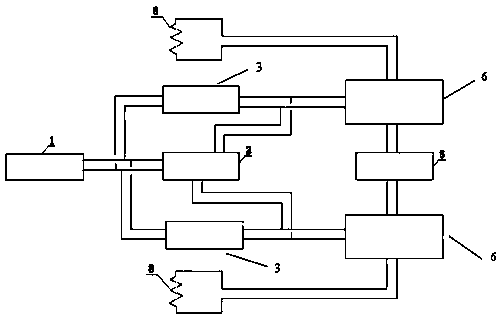

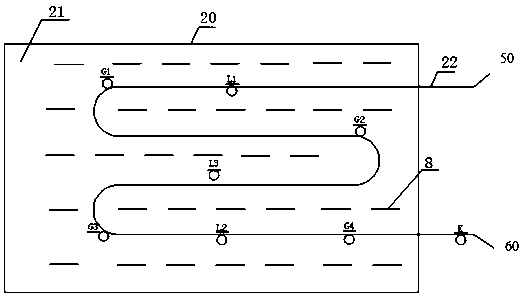

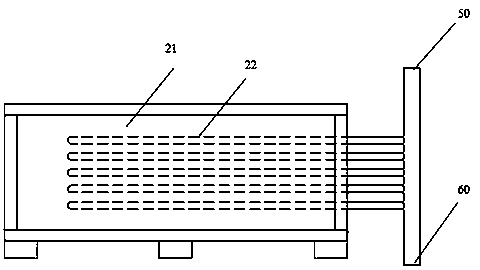

[0018] Such as figure 1 , figure 2 , image 3 As shown, this specific embodiment adopts the following technical solutions: including temperature detection point 1, DCS control room 2, intelligent temperature controller 3, 380V power supply 5, power regulator 6, heating element 8; temperature detection point 1 includes furnace tube measurement Temperature points G1, G2, G3, G4 and furnace temperature detection points L1, L2, L3 and control temperature temperature measurement point K such as figure 2 The position shown; there are five furnace tubes 22 in the hearth 21 of the horizontal cracking furnace 20, and the furnace tubes 22 have several heating elements 8;

[0019] In this embodiment, furnace temperature detection point L3, DCS control room 2, intelligent temperature controller 3, 380V power supply 5, power regulator 6, and some heating elements 8 constitute one section of the heating system; control temperature temperature measurement point K, DCS control room 2. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com