High-efficiency energy-saving cracking furnace for producing hexafluoropropylene

A hexafluoropropylene and cracking furnace technology, applied in the field of cracking furnaces, can solve the problems of small production capacity, complicated maintenance, and high power consumption of old-fashioned cracking furnaces, and achieve the effects of large production capacity, obvious energy saving, and small heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

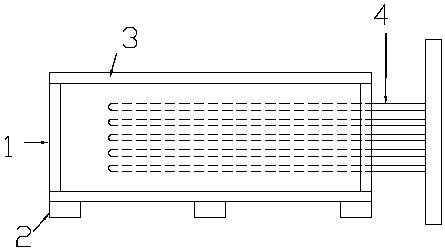

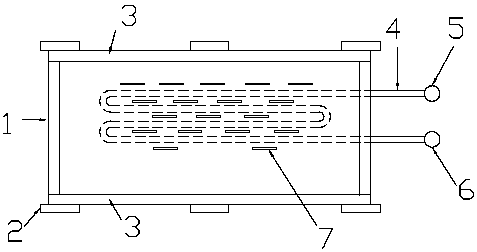

[0014] Such as Figure 1-2 As shown, a high-efficiency and energy-saving cracking furnace for producing hexafluoropropylene includes a shell 1, an insulating layer 3, a support angle 2, a feed pipe 5, a discharge pipe 6, a furnace pipe 4, and a heating plate 7. Described shell 1 is rectangular structure, and described heat-insulation layer 3 is installed inside shell 1, is provided with described furnace pipe 4 in cracking furnace, and furnace pipe 4 is placed in described heat-insulation layer 3, and furnace pipe 4 is connected in parallel in inlet. On the feed pipe 5 and the discharge pipe 6, the materials are uniformly distributed from the feed pipe 5 to the furnace pipe 4, and the materials after cracking are uniformly transferred from the discharge pipe 6 to the next process, and the furnace pipes 4 are interspersed There are several heating sheets 7, the material of the heating sheets 7 can be high temperature resistant nickel alloy 2080 material, and at the same time su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com