Low-AGEs minced fillet fried product and preparation method thereof

A technology of surimi products and surimi, applied in the field of low AGEs surimi fried products and its preparation, can solve the problems of high oil content, peroxidation, high AGEs content, etc., and achieve low fat oxidation degree, low AGEs content and fat content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

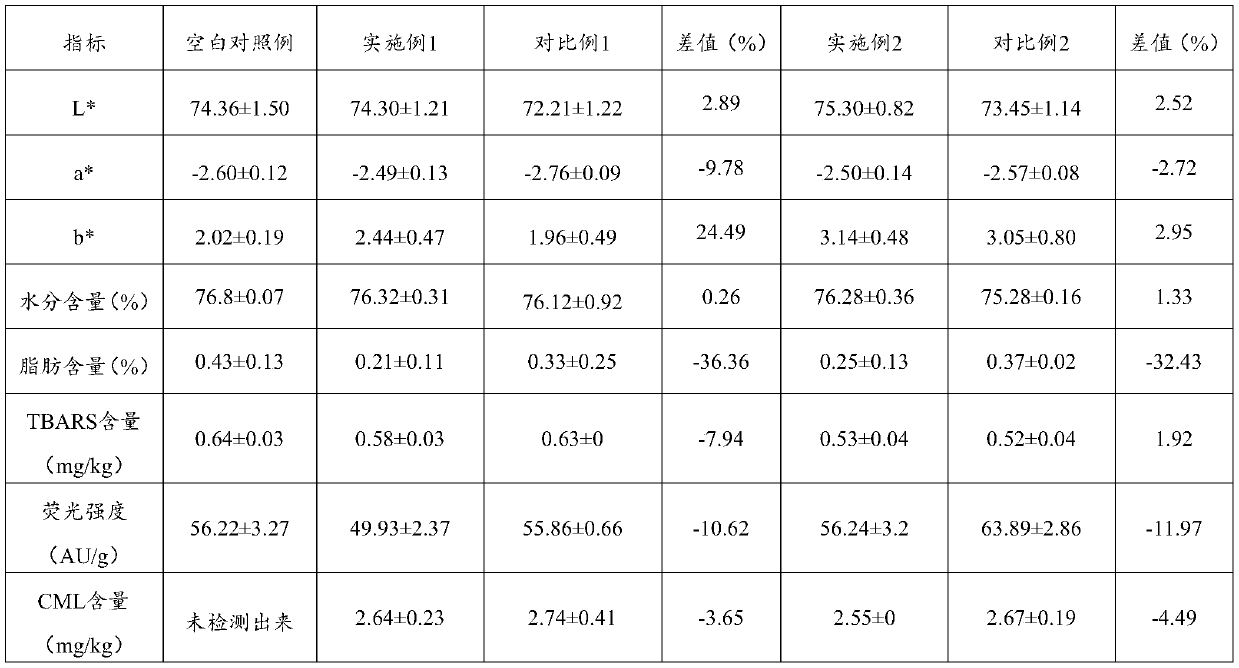

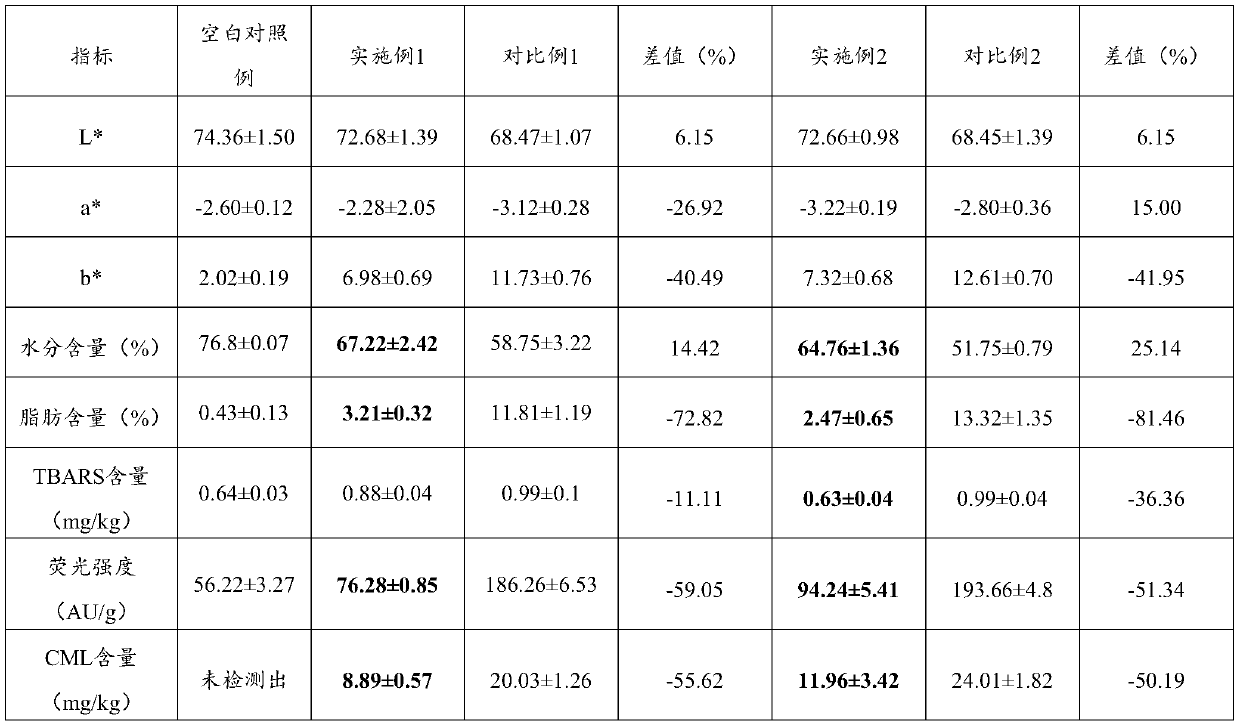

[0048] In the preparation method provided above, by preheating and then air frying, the amount of AGEs, fat content, and fat oxidation degree in the prepared surimi fried products can be greatly reduced.

[0049] Further, the present invention uses the preparation method described in any of the above-mentioned examples to prepare a low AGEs surimi fried product. Since the method of preparing the surimi fried product is preheated and then air-fried, therefore, The prepared surimi fried products have the advantages of lower AGEs content and fat content, and lower degree of fat oxidation.

Embodiment 1

[0052] Step 1: Prepare fresh surimi

[0053] Select fresh silver carp, remove the head, viscera and skin, wash and place it in a meat harvester for meat harvesting, then rinse and centrifugal dehydration to obtain surimi. Wherein, the rinsing operation includes rinsing with clean water for 2 times and rinsing with 0.3% saline for 1 time. When rinsing each time, the quality of the rinsing liquid is controlled to be 5 to 9 times the quality of the fish meat, and the quality of ice added is 1 / 7 to 1 / 5 of the quality of clean water or salt water to ensure that the entire rinsing process is carried out below 4°C.

[0054] Step 2: Prepare Surimi Preform

[0055] (1) In parts by mass, weigh 100 parts of fresh surimi prepared in step 1, 12 parts of starch, 1.5 parts of salt, 0.3 parts of monosodium glutamate, 20 parts of ice water with a temperature not exceeding 4°C, and 8 parts of ginger and onion juice.

[0056] (2) First put the surimi in a food processor and mix for 1 minute, t...

Embodiment 2

[0061] The difference from Example 1 is that in step 3-(1), the prepared surimi pre-product was heated at 40° C. for 1 hour and then heated at 90° C. for 30 minutes, and then cooled under running water. Finally, low AGEs surimi fried product B was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com