An isolated computer main circuit board dust cleaning machine

A main circuit board and computer technology, which is applied in the field of isolated computer main circuit board dust cleaning machine, can solve the problems of dust diffusion, dust diffusion in a large area, affecting the surrounding environment, etc., and achieve the effect of preventing dust diffusion and avoiding large area diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

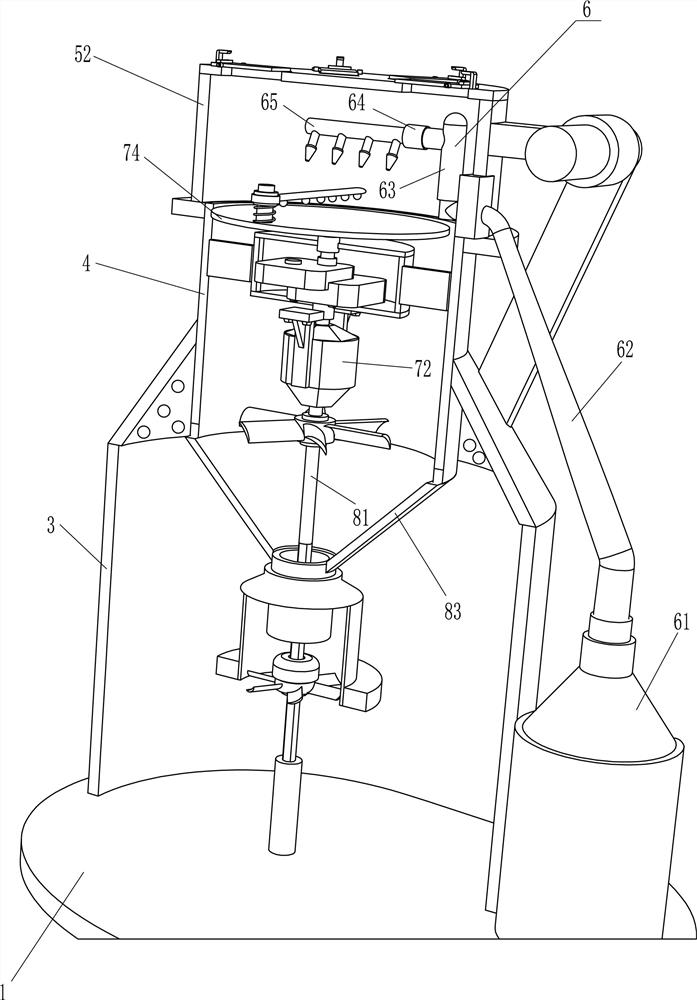

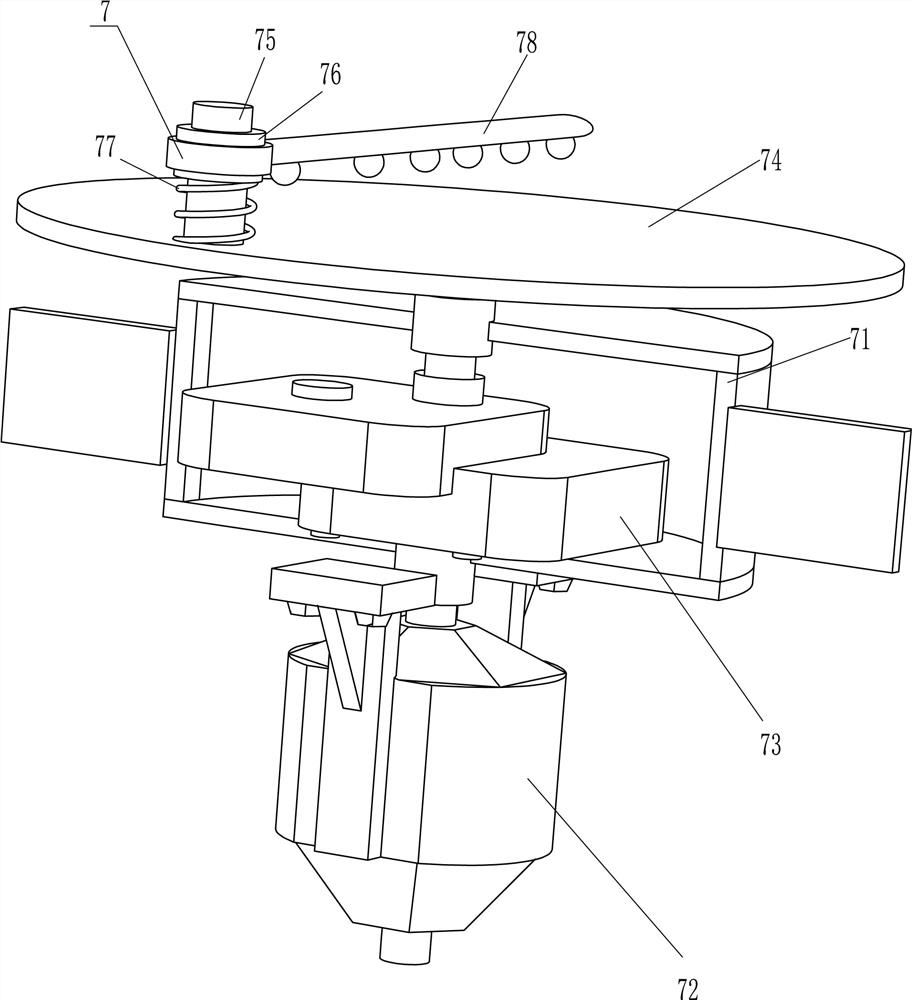

[0026] An isolated computer main circuit board dust cleaning machine, see Figure 1-3 , including a bottom plate 1, a drain valve 2, a water tank 3, a vertical pipe 4, a sealing mechanism 5, an air blowing mechanism 6 and a rotating mechanism 7, a water tank 3 is installed on the top of the bottom plate 1 through bolts, and a drain valve 2 is connected to the lower part of the front side of the water tank 3 The top of the water tank 3 is provided with a vertical pipe 4 by bolts, the vertical pipe 4 is provided with a sealing mechanism 5, the base plate 1 is provided with an air blowing mechanism 6, and the vertical pipe 4 is provided with a rotating mechanism 7.

[0027] The sealing mechanism 5 includes a pole 51 and a seal cover 52. The upper part of the water tank 3 right side is connected with a pole 51. The pole 51 is arranged in an inclined manner. The top of the pole 51 is rotatably connected with a seal cover 52. 4 Cover.

[0028] The blowing mechanism 6 includes a boo...

Embodiment approach 2

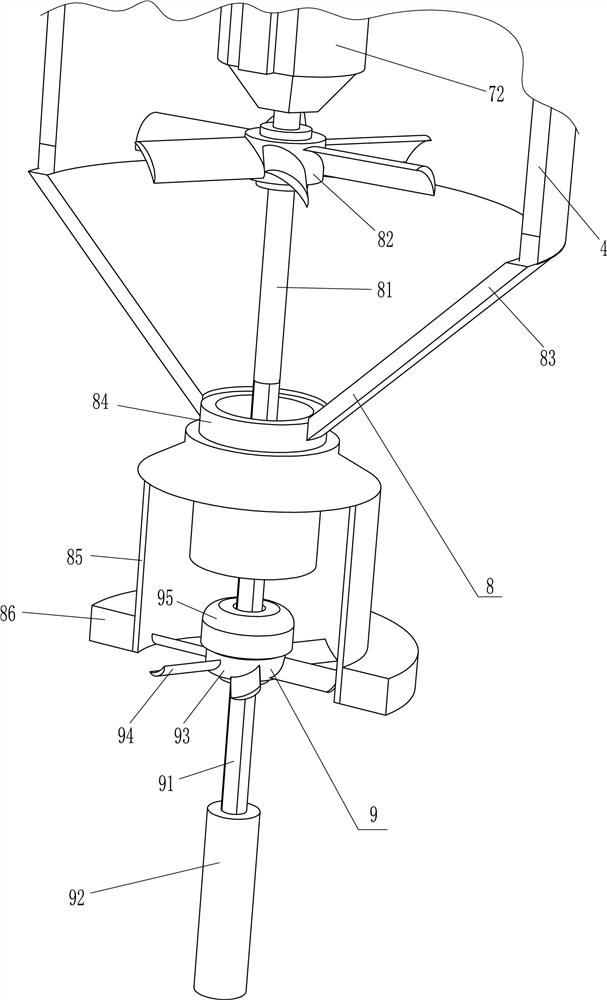

[0035]On the basis of Embodiment 1, see figure 1 , figure 2 , Figure 4 with Figure 5 , also includes an exhaust mechanism 8, the exhaust mechanism 8 includes a rotating rod 81, an exhaust fan 82, a gas gathering cone pipe 83, a guide pipe 84, a slide pipe 85 and a floating ring 86, and on the output shaft below the drive motor 72 A rotary rod 81 is connected through a coupling, and the upper part of the rotary rod 81 is connected with an exhaust fan 82 through a flat key. A slide tube 85 is slidably arranged on the guide tube 84, and a floating ring 86 is connected to the outer lower part of the slide tube 85, and air inlets 87 are evenly spaced on the top of the sealing cover 52 around the circumferential direction.

[0036] Also includes a fusion mechanism 9, the fusion mechanism 9 includes a square rod 91, a connecting sleeve 92, a square hole sleeve 93, a stirring blade 94 and a floating block 95, the bottom end of the rotating rod 81 is connected with a square rod 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com