Angle steel welding and positioning device and welding equipment using positioning device

A welding positioning and welding equipment technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as bowing, and achieve the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

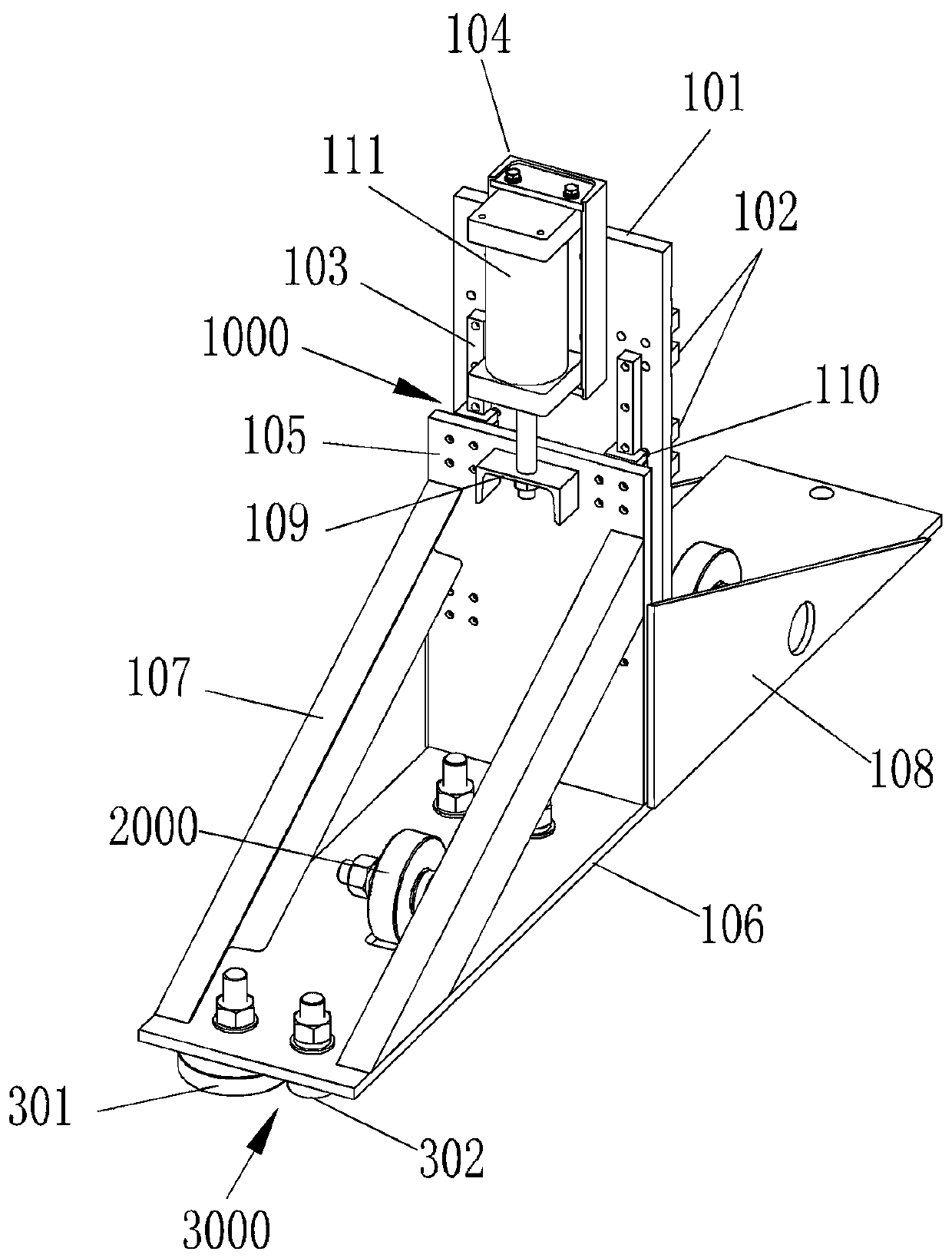

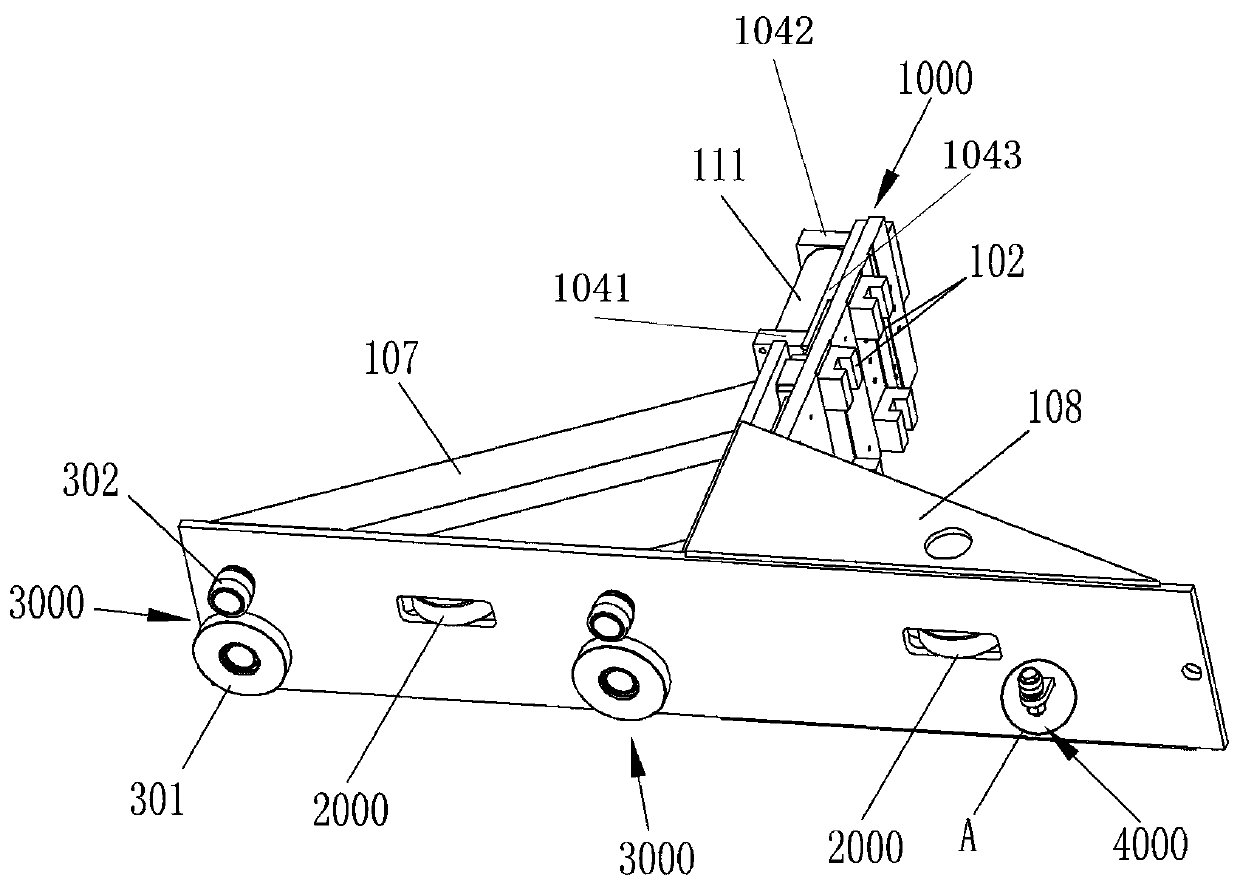

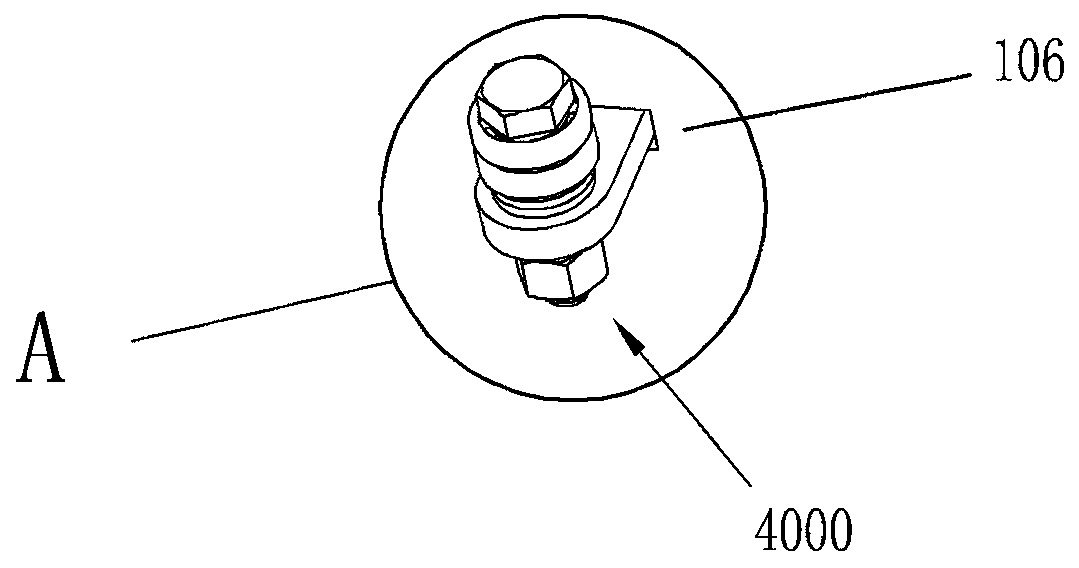

[0036] Such as Figure 1-7 As shown, in this embodiment, the main components of the angle steel welding positioning device include a mounting frame 1000 , a pressing wheel 2000 , a clamping wheel set 3000 and a centralizing body 4000 .

[0037] The mounting frame 1000 is a combined frame, including a fixed part, a movable part and a pressing driving device installed between the fixed part and the movable part. The fixed part includes a base plate 101 , a base plate slider 102 , a movable plate slide rail 103 , and a cylinder seat 104 . The movable part comprises a movable plate 105, a base plate 106, a reinforcing brace 107, a rib plate 108, a cylinder connector 109 and a movable plate slider 110, and the pressing driving device is an air cylinder 111.

[0038] The substrate slider 102 is installed on the back of the substrate 101 and has upper and lower layers. Each substrate slider 102 is provided with a chute for installing the substrate 101 on the door frame 501 of the tr...

specific Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 of the angle steel welding positioning device is that in this embodiment, the stabilizer adopts a slider instead of a bearing. As mentioned above, the function of the centralizer is to hold the horizontal part of the angle steel and prevent it from falling down. In order to meet this requirement, in other embodiments, the centralizer can actually use a fixed-axis rolling body such as a general roller, or a universal Universal rolling elements such as wheels.

specific Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 of the angle steel welding positioning device is that in this embodiment, the centralizer and the corresponding (relatively close) pinch wheel are staggered in the longitudinal direction, and in other embodiments, the It can also be aligned with the centralizing body in the longitudinal direction, and the centralizing body and the pressing wheel can be arranged in a horizontal direction. Together with the centralizing body and the pressing wheel, the unevenness on the horizontal part of the angle steel can be flattened.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap