Holmium ferrite-based terahertz metamaterial and its preparation method and optical device

A holmium ferrite-based and metamaterial technology, applied in the field of terahertz metamaterials, can solve the problems of inability to adjust the ratio of Ho atoms to Fe atoms, cumbersome operation, and inflexibility, and achieve excellent controllability of the amplitude and frequency of terahertz electromagnetic waves Features, important application prospects, and the effect of avoiding large absorption losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

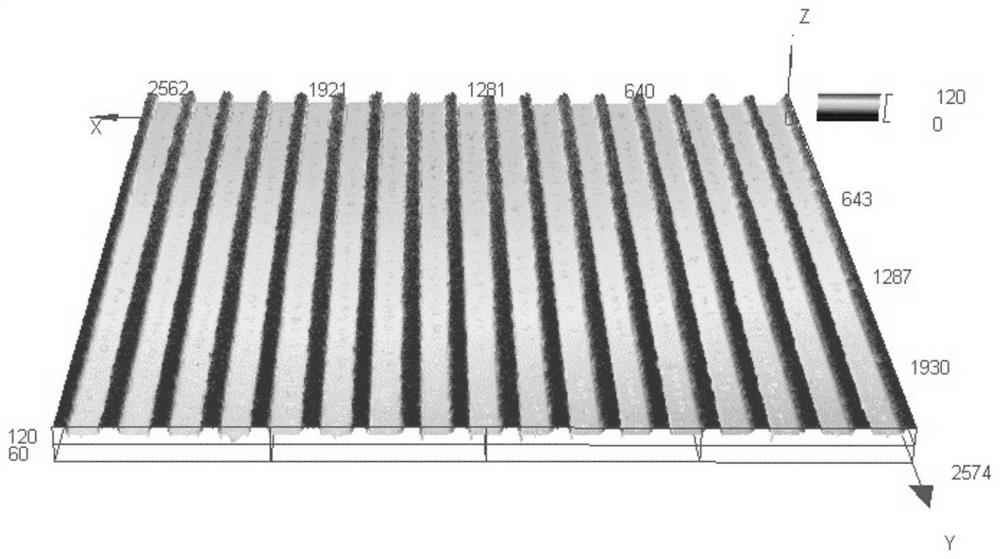

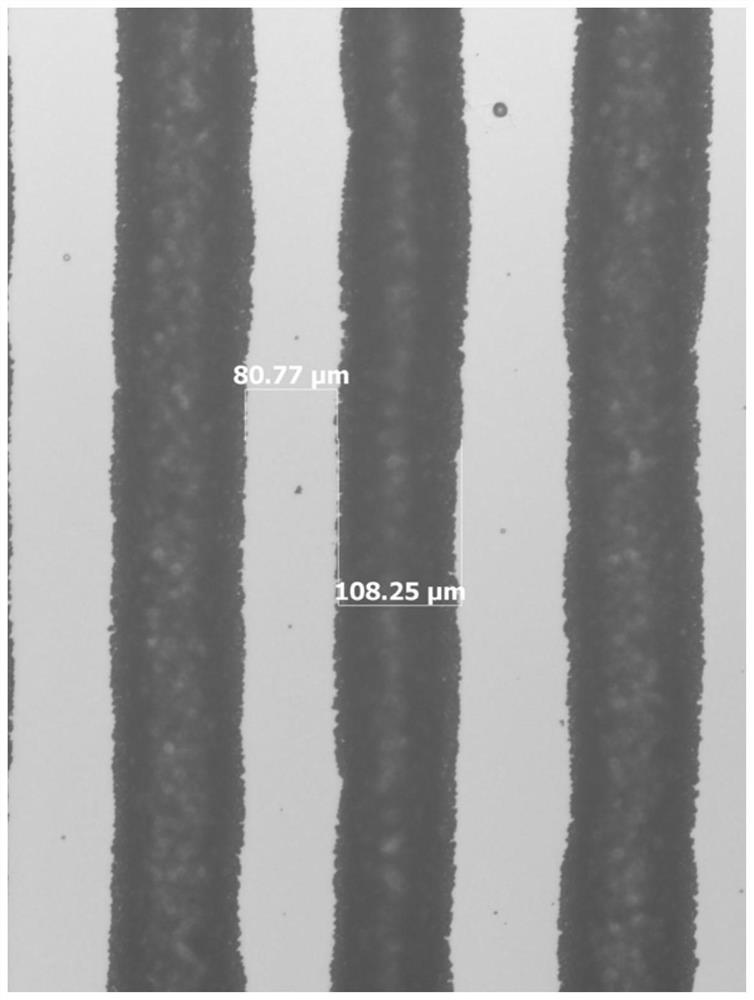

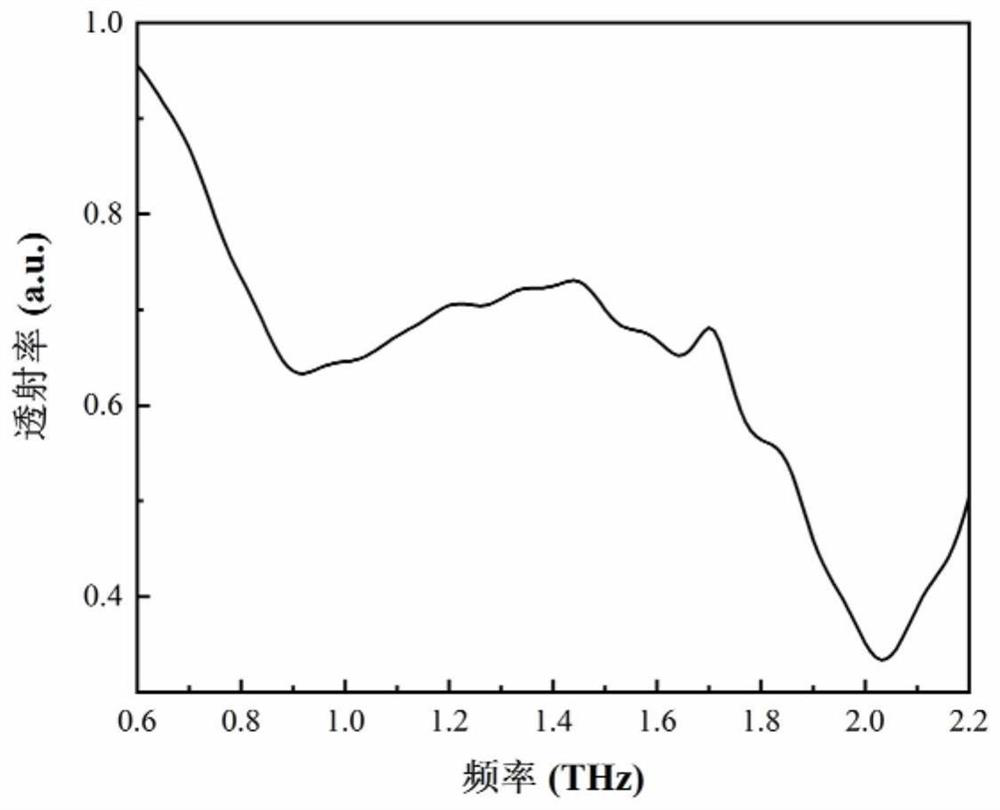

[0029] This embodiment provides a holmium ferrite-based terahertz metamaterial, and the terahertz metamaterial is a grating structure and is prepared according to the following steps:

[0030] (1) Mix 1moL iron oxide and 1moL holmium oxide to form a raw material mixture, and then perform the first sintering at 900 °C to form a holmium ferrite-based material HoFeO 3 , and then ball milled at 3000r / min to form powder;

[0031] (2) Take the holmium ferrite-based material HoFeO in step (1) 3 powder, add the aqueous solution of polyvinyl alcohol and uniformly mix to form a slurry, wherein, in the slurry, the holmium ferrite-based material HoFeO 3 The mass fraction is 90%, and then the above slurry is printed and formed by 3-D direct writing equipment, and then sintered for a second time at 1400 ° C for 4 hours. The obtained holmium ferrite-based terahertz metamaterial is a long strip material. The grating structure is formed, the sample size of the grating structure is 10mm × 10m...

Embodiment 2

[0034] The present embodiment provides a ferrite-based terahertz metamaterial, and the ferrite-based terahertz metamaterial has a face-centered cubic structure and is prepared according to the following steps:

[0035] (1) Mix 1moL of iron oxide and 1moL of holmium oxide to form a raw material mixture, and then perform first sintering at 900°C to form HoFeO, a holmium ferrite-based material 3 , and then ball milled at 3000r / min to form powder;

[0036] (2) Take the holmium ferrite-based material HoFeO in step (1) 3 powder, add the aqueous solution of polyvinyl alcohol and uniformly mix to form a slurry, wherein, in the slurry, the holmium ferrite-based material HoFeO 3 The mass fraction is 90%, then 3-D direct writing equipment is used to print the slurry layer by layer, and then the second sintering is performed at 1400 ° C for 4 hours to obtain the holmium ferrite-based terahertz metamaterial as a long strip material. The face-centered cubic structure is formed. The sample...

Embodiment 3

[0039] This embodiment provides a holmium ferrite-based terahertz metamaterial, and the terahertz metamaterial is a grating structure and is prepared according to the following steps:

[0040] (1) Mix 0.8moL iron oxide and 1.2moL holmium oxide to form a raw material mixture, and then perform the first sintering at 900°C to form a holmium ferrite-based material Ho 1.2 Fe 0.8 O 3 , and then ball milled at 3000r / min to form powder;

[0041](2) Take the holmium ferrite-based material ceramic powder Ho in step (1) 1.2 Fe 0.8 O 3 Powder, add the aqueous solution of polyvinyl alcohol and uniformly mix to form a slurry, wherein, in the slurry, the holmium ferrite-based material ceramic powder Ho 1.2 Fe 0.8 O 3 The mass fraction is 90%, then 3-D direct writing equipment is used to print the paste layer by layer, and then the second sintering is performed at 1400 ° C for 4 hours to obtain the holmium ferrite-based terahertz metamaterial as a grating structure. The sample size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com