Reactive red dye composition, dye product and application thereof

A reactive red dye and composition technology, applied in the field of reactive red dye composition and dye products, can solve the problems of poor alkali resistance and low color fastness, and achieve outstanding light fastness and washing fastness, alkali resistance Good, excellent color fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

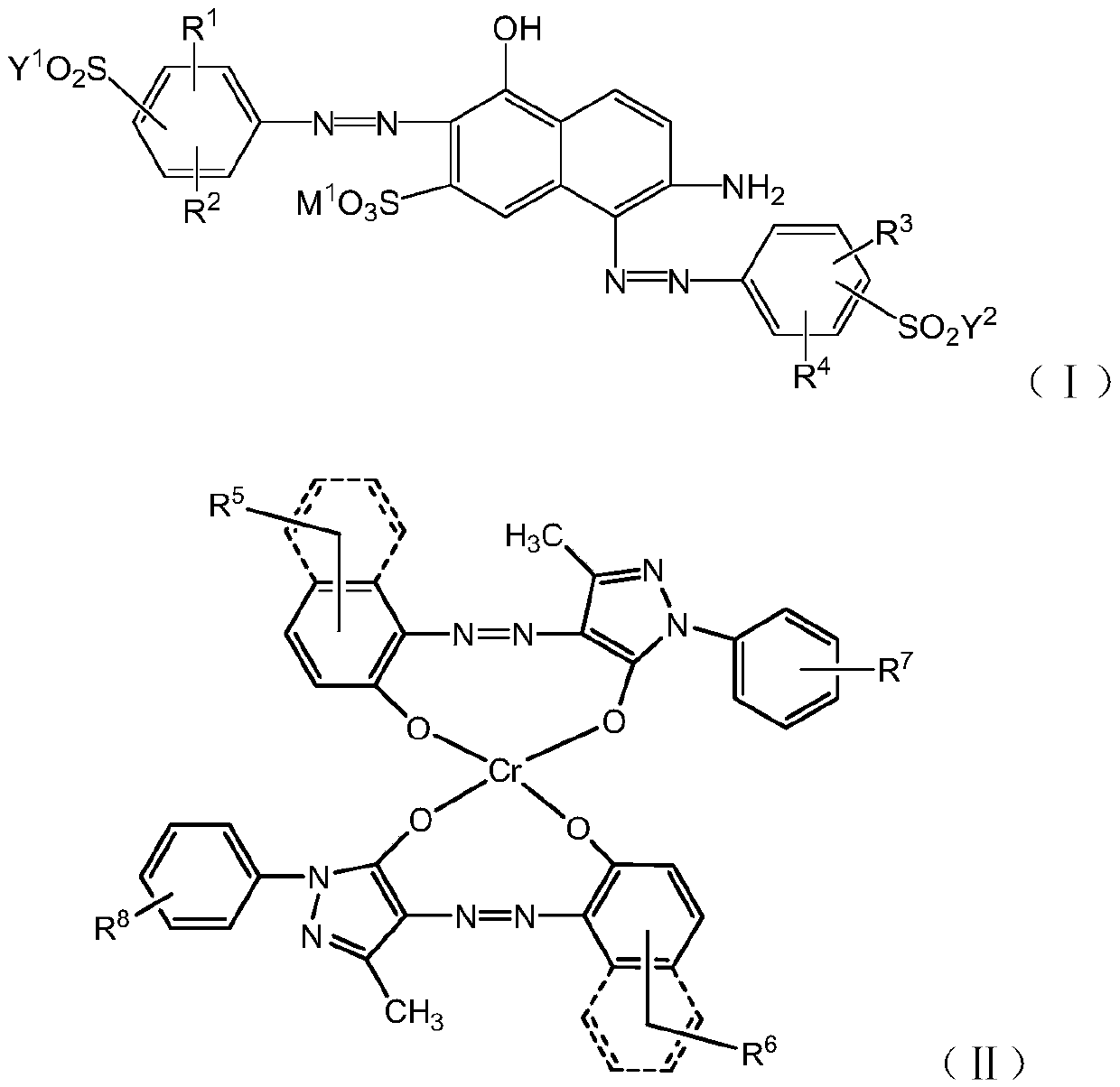

Method used

Image

Examples

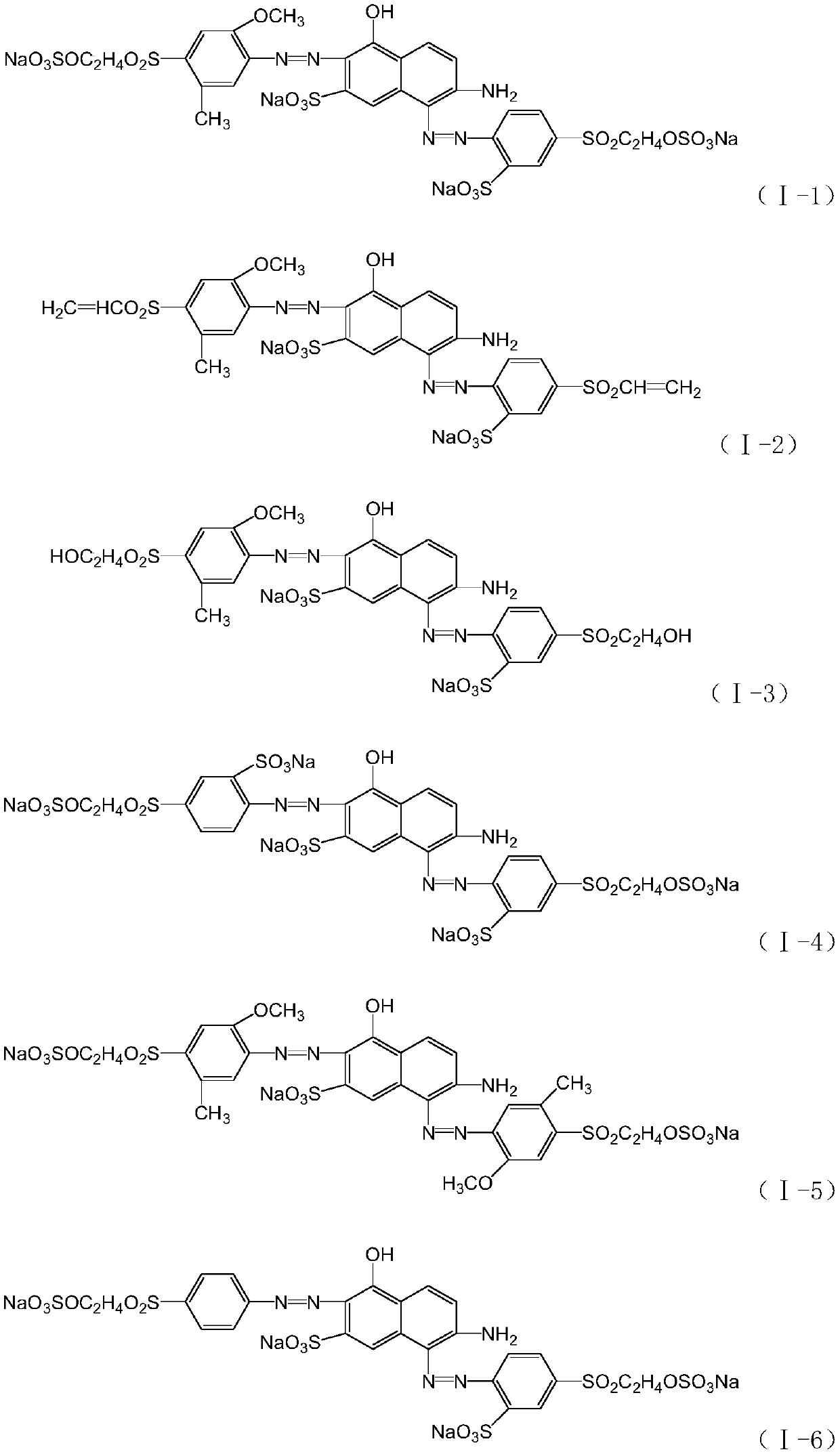

Embodiment 1

[0045]Component A of 85 grams of formula (I-1), component B of 15 grams of formula (II-1), and 10 grams of sodium sulfate are mechanically mixed, and the dyes obtained can dye cotton fabrics red.

[0046]

Embodiment 2

[0048] Component A of 80 grams of formula (I-2), component B of 20 grams of formula (II-2), and 15 grams of sodium sulfate are mechanically mixed, and the dye obtained can dye cotton fabric red.

[0049]

[0050]

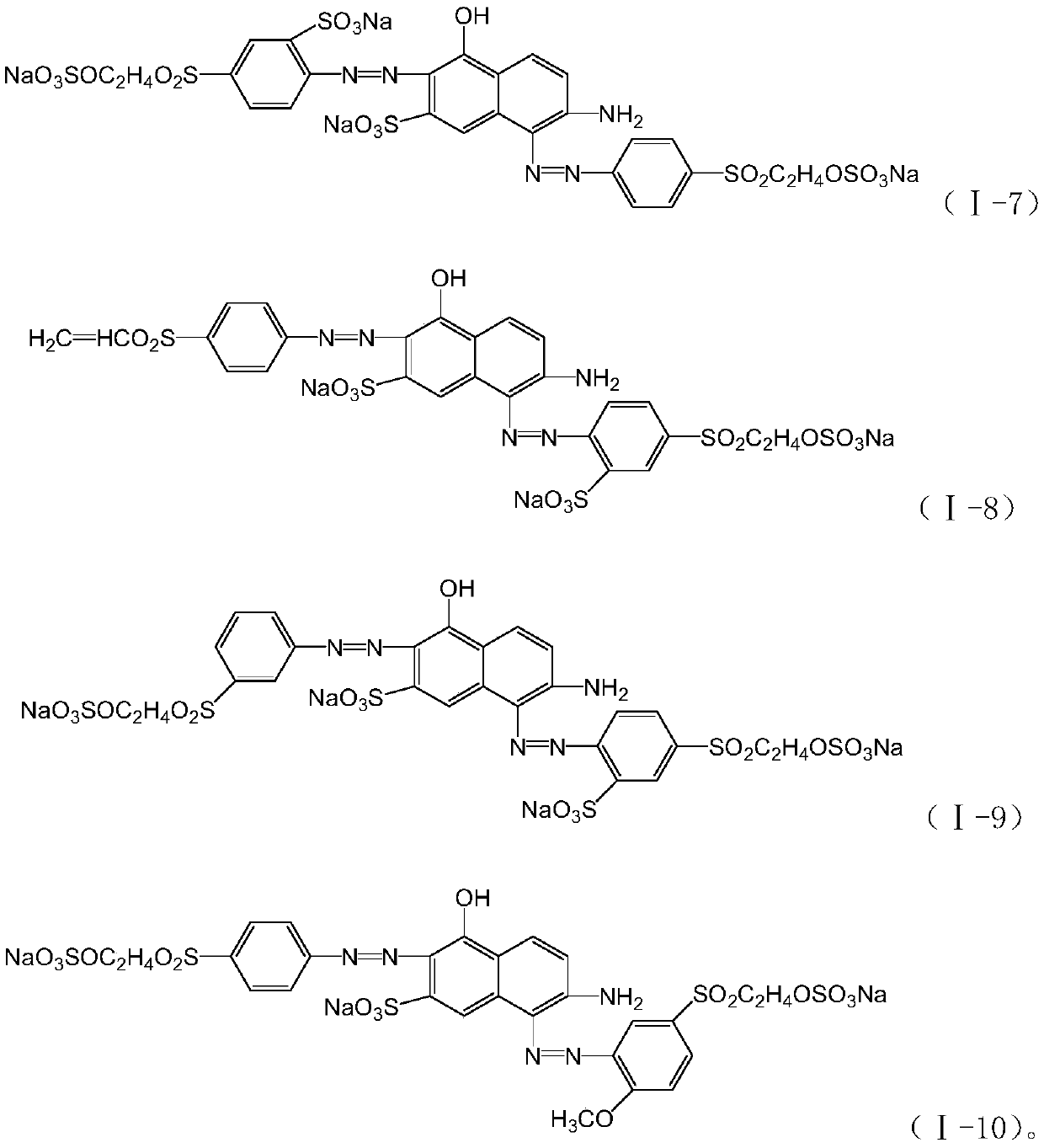

Embodiment 3~30

[0052] According to the method described in embodiment 1, difference is to adopt the kind and the weight of component A, component B and auxiliary agent in table 1, carry out mechanical mixing equally, obtain reactive dyestuff of the present invention and cotton fabric can be dyed as red.

[0053] Table 1

[0054]

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com