A mud-stripping method for quick recovery of mud bag falling off at the front end of iron mouth

A fast recovery and taphole technology, applied in the direction of furnace, furnace type, blast furnace parts, etc., to achieve the effect of cleaning slag and iron, ensuring stable and straight line, and restoring the depth of taphole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

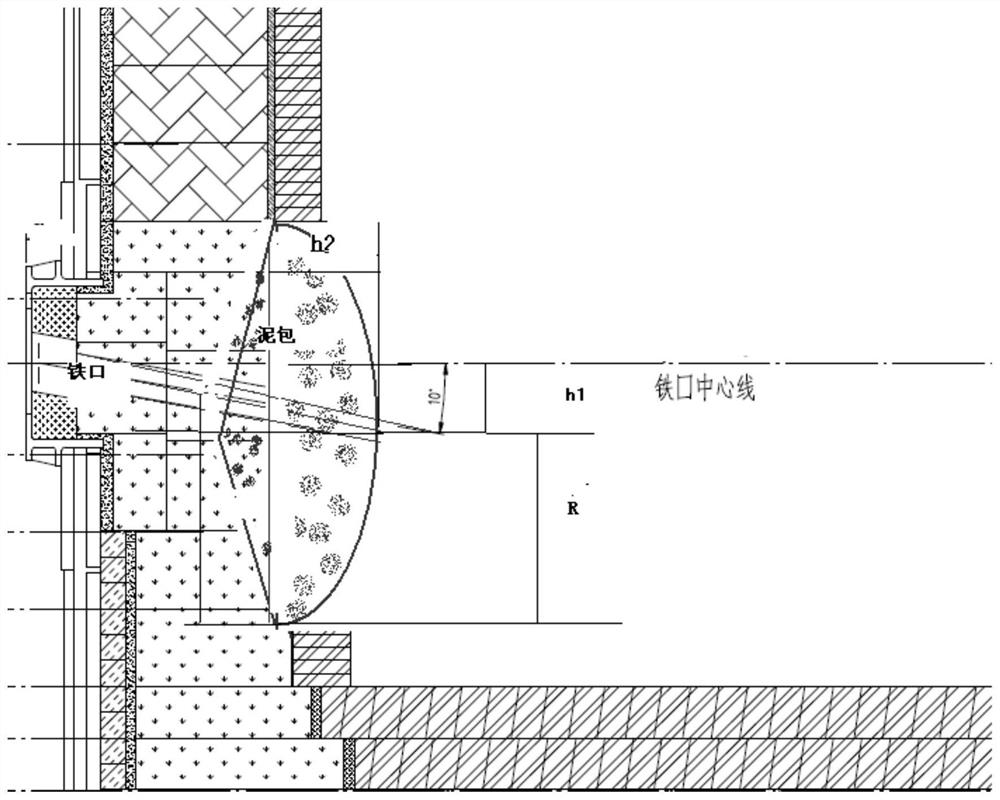

[0043] See figure 1 , the diameter of a blast furnace hearth is 11.5m, the diameter of the tapping drill pipe is d=0.050m, and the angle of the taphole is α=10°. The selection of the dredging amount of the blast furnace is realized by the following steps:

[0044] 1. According to the diameter of blast furnace hearth (D h ,m) Select the tap hole depth (L t ,m), substituting into formula (1) to get:

[0045] L t =45%×D h / 2=2.6m

[0046] 2. Calculate the amount of mud pumping in the iron mouth channel

[0047] Iron mouth channel volume (V 1 ,m 3 ), substituting into formula (2) to get:

[0048] V 1 =1 / 4×3.14×d 2 × L t =0.005m 3

[0049] Clay bulk density 1.7t / m 3 , then the amount of mud dredging in the iron mouth channel (Q 1 ,kg), substituting into formula (3) to get:

[0050] Q 1 =1.7×V 1 ×1000=9kg

[0051] 3. The amount of mud pumped by the mud bag at the front end of the iron hole:

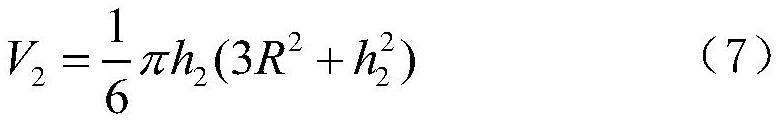

[0052] The mud bag at the front end of the tap hole is required to form...

Embodiment 2

[0068] See figure 1 , the diameter of a blast furnace hearth is 11.5m, the diameter of the tapping drill pipe is d=0.055m, and the angle of the taphole is α=10°. The blast furnace can choose the amount of iron and mud for each time through the following steps:

[0069] 1. According to the diameter of blast furnace hearth (D h ,m) Select the tap hole depth (L t ,m), substituting into formula (1) to get:

[0070] L t =50%×D h / 2=2.9m

[0071] 2. Calculate the amount of mud pumping in the iron mouth channel

[0072] Iron mouth channel volume (V 1 ,m 3 ), substituting into formula (2) to get:

[0073] V 1 =1 / 4×3.14×d 2 × L t =0.007m 3

[0074] Clay bulk density 1.7t / m 3 , then the amount of mud dredging in the iron mouth channel (Q 1 ,kg), substituting into formula (3) to get:

[0075] Q 1 =1.7×V 1 ×1000=12kg

[0076] 3. The amount of mud pumped by the mud bag at the front end of the iron hole:

[0077] The mud bag at the front end of the tap hole is required t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com