Method for calculating pressure of small combustion chamber of double-combustion-chamber solid rocket engine

A solid rocket, dual-combustion chamber technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as no similar mature algorithms, and achieve the effect of speeding up the development progress and facilitating parameter adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings and Table 1.

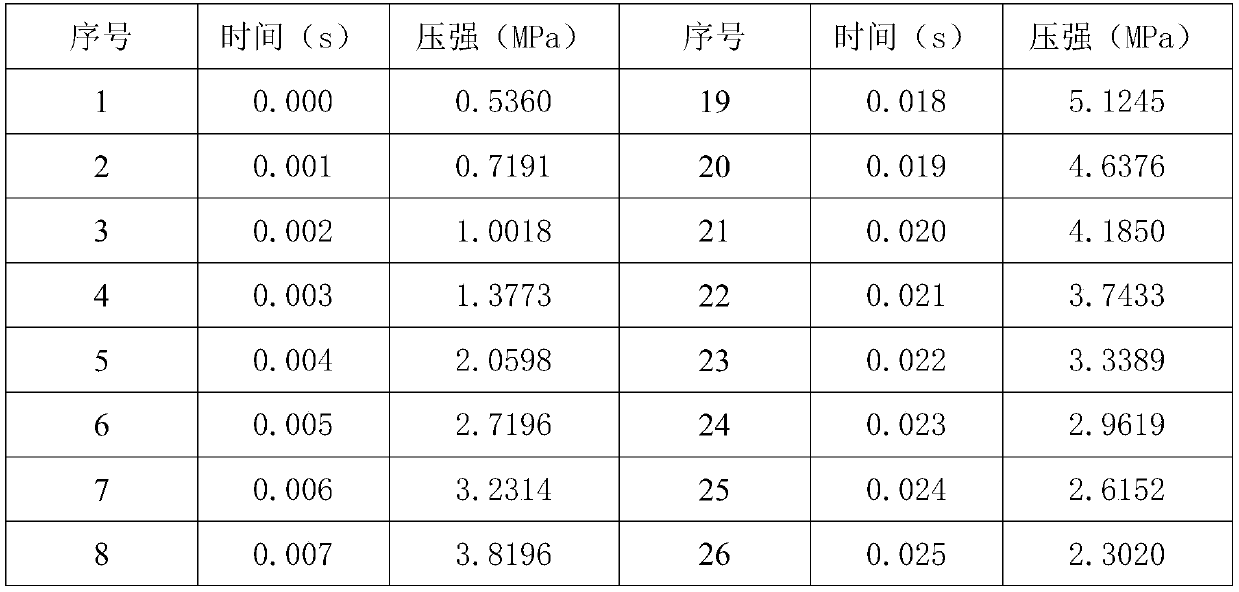

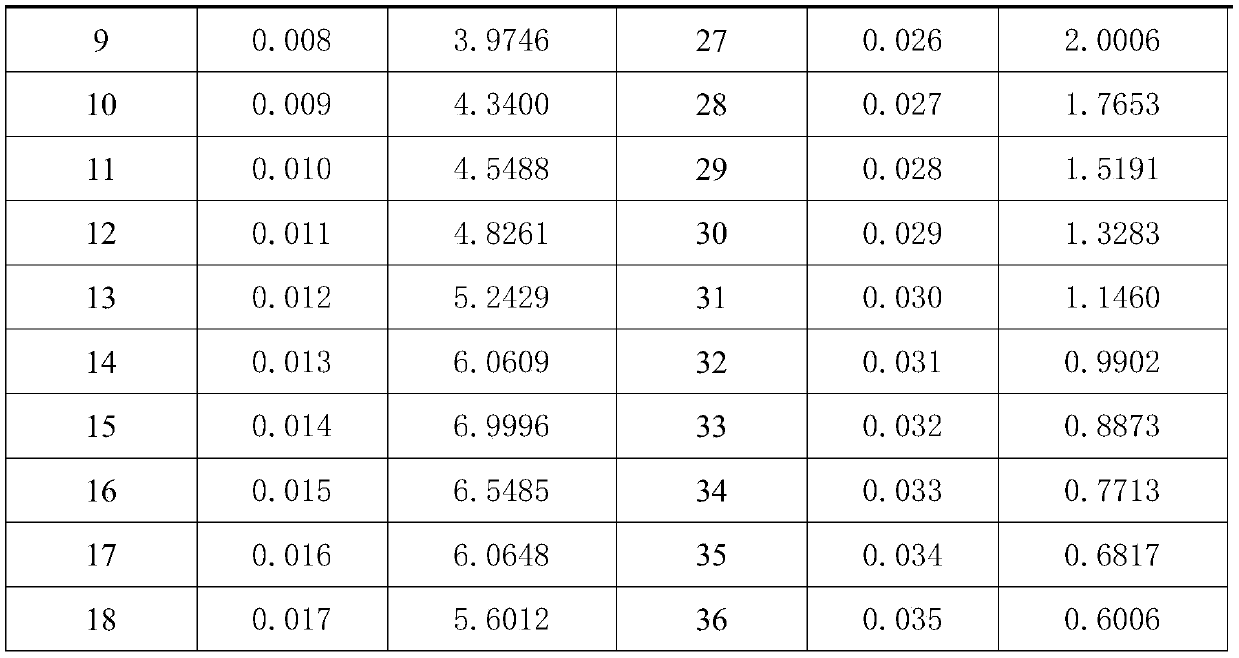

[0032] Table 1 Pressure sampling data of large combustion chamber

[0033]

[0034]

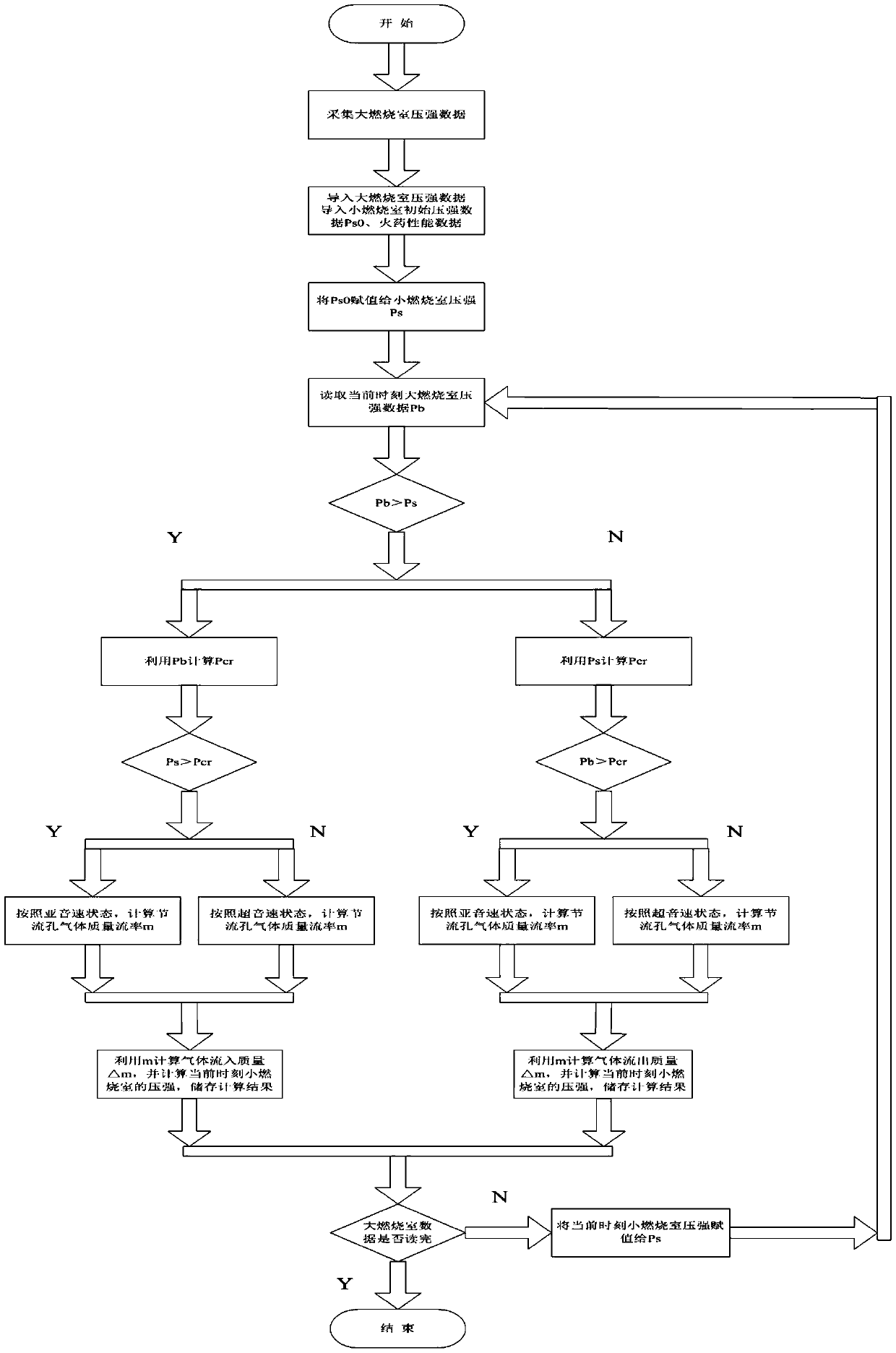

[0035] see figure 1 , the method for calculating the pressure of the small combustor of the dual-combustion chamber solid rocket motor includes the following steps:

[0036] (1) First collect the large combustion chamber pressure data of a certain double combustion chamber solid rocket motor, Table 1 test data (sampling frequency is 1kHz);

[0037] (2) Import the data file, the initial pressure P of the small combustion chamber S 0 is 0.1MPa, and the propellant performance data is total temperature 2800K, gas specific heat ratio 1.22, gas molecular weight 224.6J / (kg·K);

[0038] (3) The initial pressure P of the small combustion chamber S 0 is 0.1MPa assigned to the pressure Ps of the small combustion chamber, and the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com