Chain link unit

A technology of chains and inner chain plates, which is applied in the field of chains and can solve problems such as increased cost and weight, high cost, and easy elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

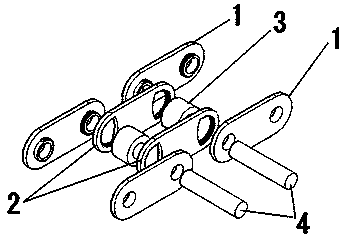

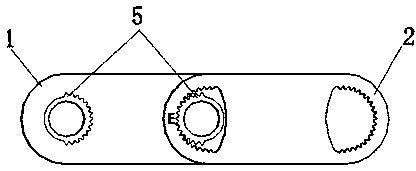

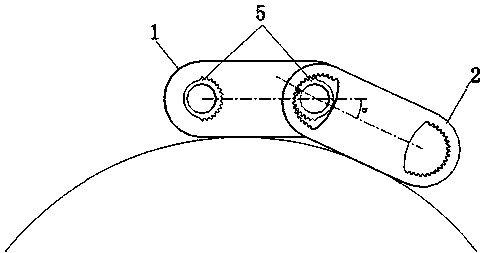

[0008] refer to figure 1 figure 2 , the chain link unit of the present invention includes an outer chain plate 1, an inner chain plate 2, a pin shaft 4, and a shaft sleeve 3. The outer chain plate 1 has pitch holes as required, and some teeth are fixed at the inner pitch holes of the outer chain plate 1. The outer gear ring 5 and the inner chain plate 2 are perforated according to the pitch, and some teeth are processed in the pitch hole of the inner chain plate. During installation, the outer shaft sleeve 3 of the pin shaft 4 is a clearance fit, and then the two ends of the pin shaft 4 respectively pass through the pitch holes of the inner chain plate 2 and then interference fit the pitch holes of the outer chain plate 1. The inner teeth of the inner chain plate 2 mesh with the outer teeth of the outer gear ring 5 of the outer chain plate 1, and the part without teeth in the pitch hole of the inner chain plate 1 and the part without teeth of the outer gear ring 5 fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com