Rotary compressor

A rotary compressor and rotary shaft technology, applied in the field of compressors, can solve the problems of increasing the friction area between blades and cylinders, increasing mechanical friction loss, etc., and achieve the effects of reducing mechanical friction loss, reducing pressure pulsation, and stabilizing the contact state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

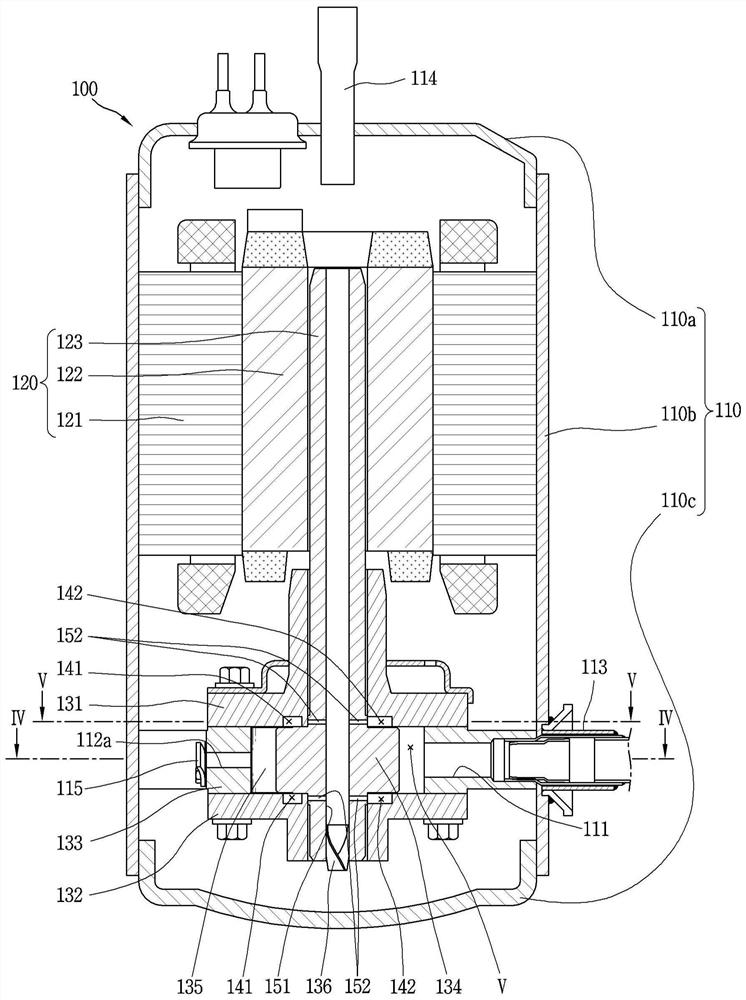

[0059] Hereinafter, the rotary compressor according to the present invention will be described in detail with reference to the accompanying drawings.

[0060] In this specification, expressions in the singular shall include expressions in the plural unless the context clearly indicates otherwise.

[0061] During the description of the embodiments disclosed in this specification, if it is determined that the specific description of the related well-known technology makes the gist of the embodiments disclosed in this specification unclear, the detailed description thereof will be omitted.

[0062] The accompanying drawings are only to help understand the embodiments disclosed in this specification, the technical ideas disclosed in this specification are not limited by the accompanying drawings, and it should be understood that the present invention includes all changes, equivalents and substitutes within the technical scope of the present invention.

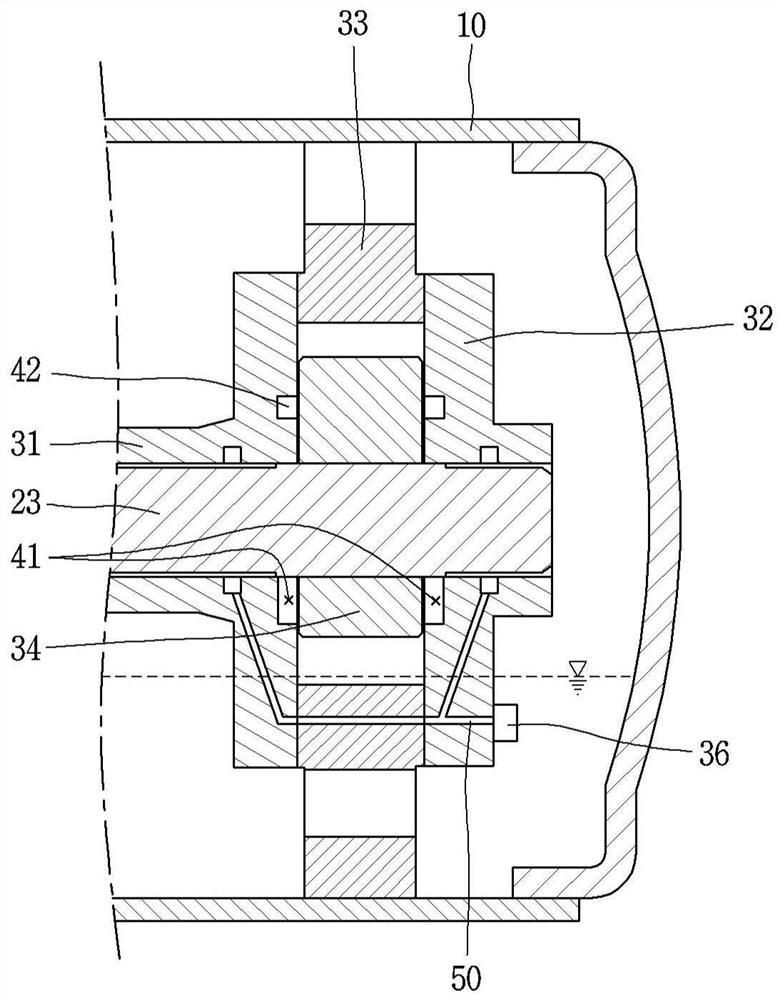

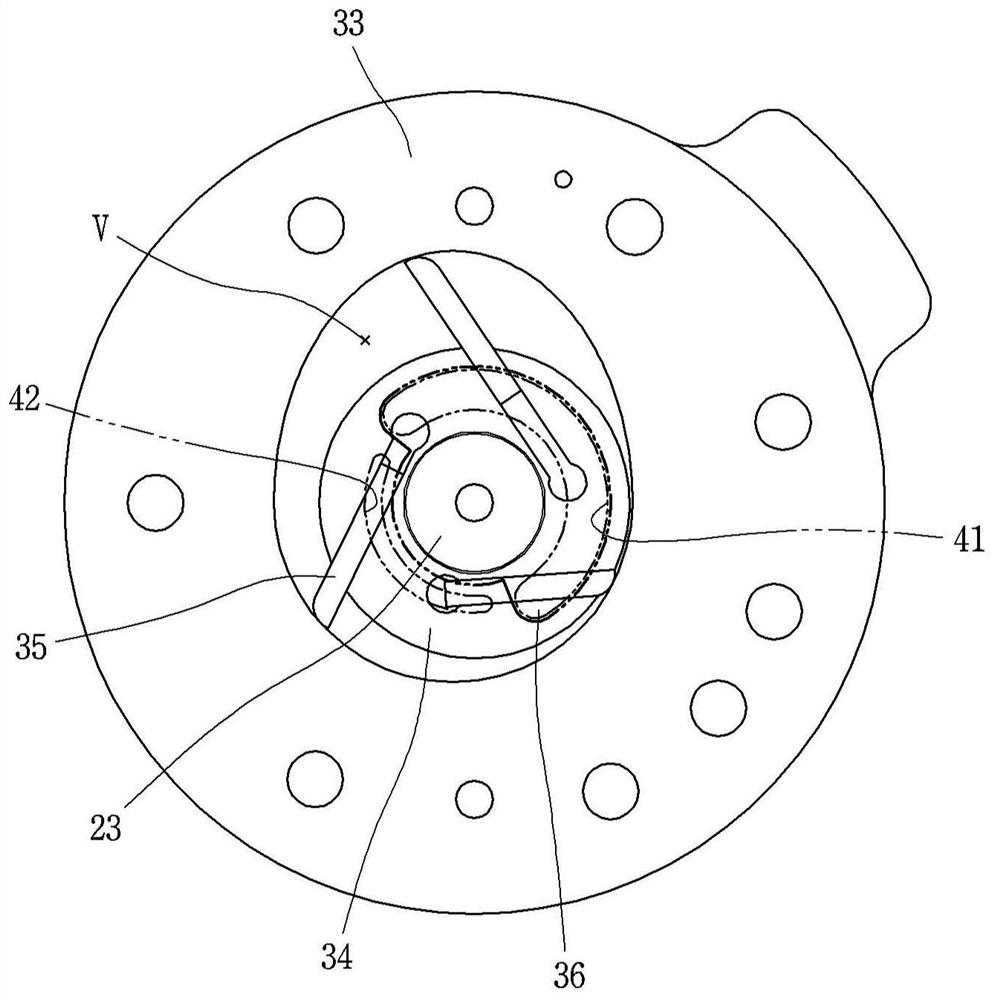

[0063] image 3 It is sect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap