A kind of graphite-like hollow microsphere photocatalyst and its preparation method and application method

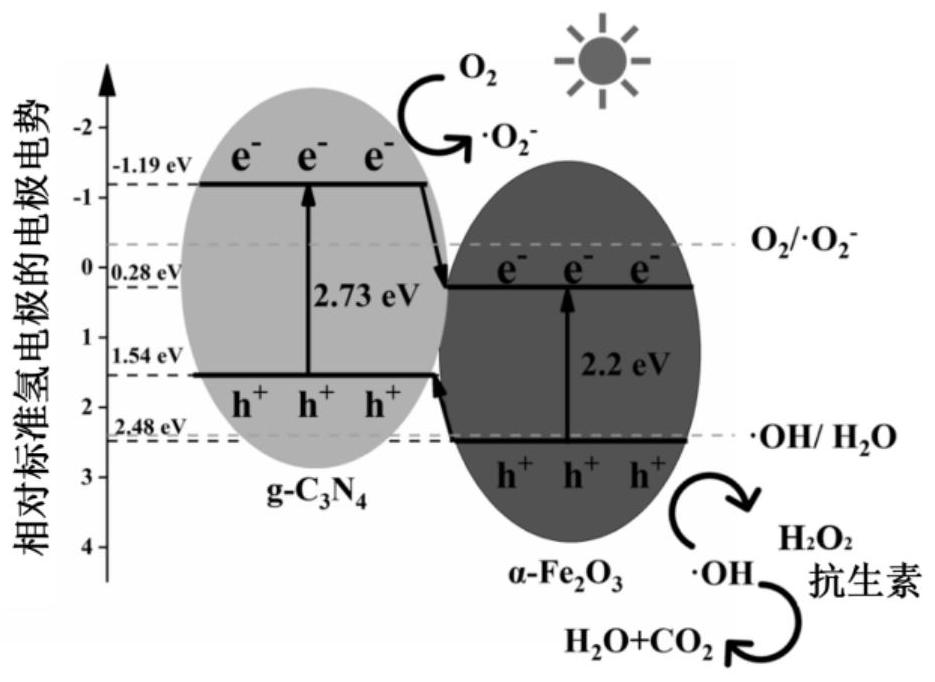

A photocatalyst, hollow microsphere technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Sufficient, morphology limited photon absorption and other issues, to achieve the effect of improving activity and stability, avoiding collapse, and increasing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

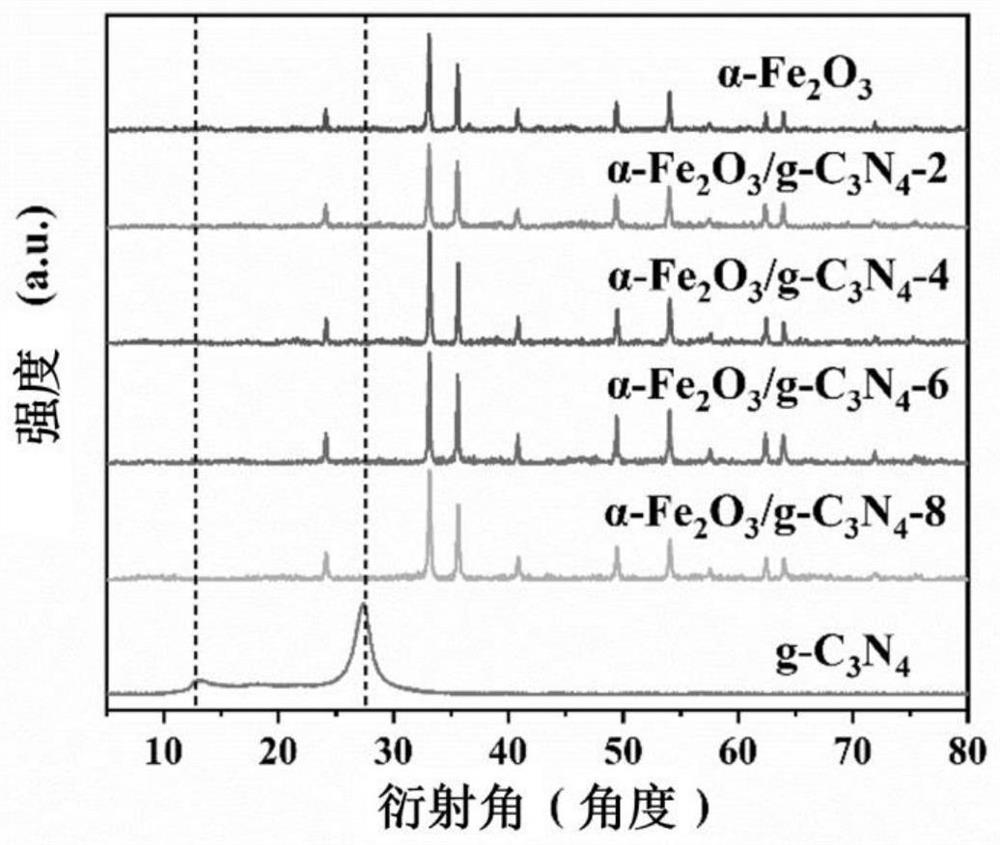

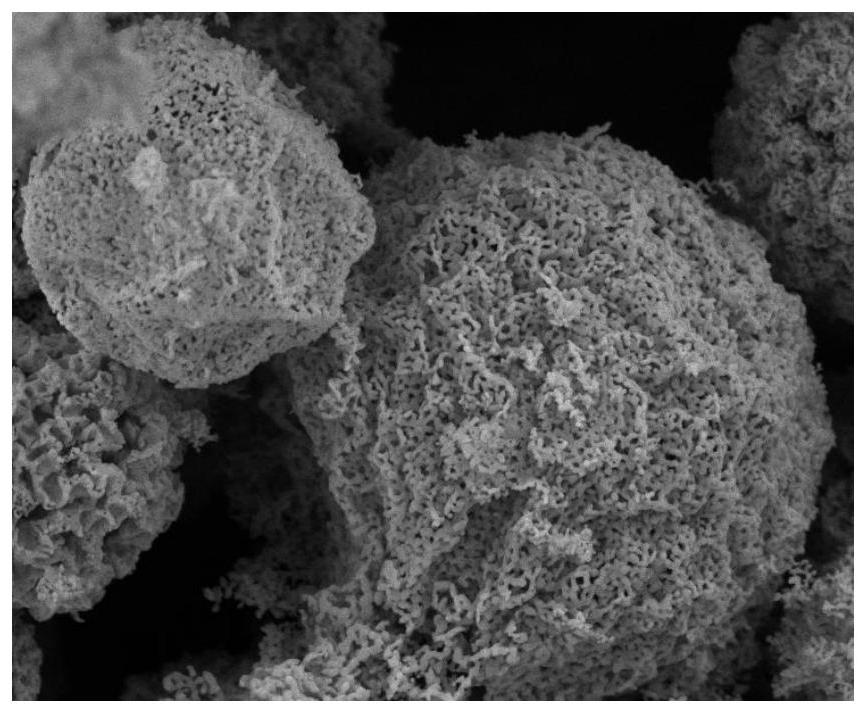

[0036] The graphite-like hollow microsphere photocatalyst of the present embodiment is prepared through the following steps:

[0037] (1) Dissolve 1 mmol of ferric nitrate in 50 mL of deionized water under stirring to form a homogeneous solution. Subsequently, 2 mmol of dicyandiamide and 25 mmol of glucose were introduced, 10 mmol of ethylene glycol was added and the resulting mixture was sonicated for 30 minutes with continuous stirring for 30 minutes;

[0038] (2) Transfer the homogeneous solution into a 100 mL Teflon-lined stainless steel autoclave and heat at 180 °C for 20 h. After naturally cooling to room temperature, the suspension was centrifuged at 8000r / min for 10min, washed with deionized water and absolute ethanol three times, and dried overnight at 80°C in air;

[0039] (3) The product prepared by the former was introduced into an alumina crucible with a cover, and then heated to 550° C. in a muffle furnace at a heating rate of 2° C. / min, and kept for 3 hours. A...

Embodiment 2

[0042] The graphite-like hollow microsphere photocatalyst of the present embodiment is prepared through the following steps:

[0043] (1) Dissolve 1 mmol of ferric nitrate in 25 mL of deionized water under stirring to form a homogeneous solution. Subsequently, 20 mmol of dicyandiamide and 25 mmol of glucose were introduced, 10 mmol of ethylene glycol was added and the resulting mixture was sonicated for 30 minutes with continuous stirring for 30 minutes;

[0044] (2) Transfer the homogeneous solution into a 100 mL Teflon-lined stainless steel autoclave and heat at 180 °C for 20 h. After naturally cooling to room temperature, the suspension was centrifuged at 8000r / min for 10min, washed with deionized water and absolute ethanol three times, and dried overnight at 80°C in air;

[0045](3) The product prepared by the former was introduced into an alumina crucible with a cover, and then heated to 550° C. in a muffle furnace at a heating rate of 2° C. / min, and kept for 3 hours. A...

Embodiment 3

[0048] The graphite-like hollow microsphere photocatalyst of the present embodiment is prepared through the following steps:

[0049] (1) Dissolve 1 mmol of ferric nitrate in 35 mL of deionized water under stirring to form a homogeneous solution. Subsequently, 4 mmol of dicyandiamide and 25 mmol of glucose were introduced, 10 mmol of ethylene glycol was added and the resulting mixture was sonicated for 30 minutes with continuous stirring for 30 minutes;

[0050] (2) The homogeneous solution was transferred to a 100 mL Teflon-lined stainless steel autoclave and heated at 200 °C for 20 h. After naturally cooling to room temperature, the suspension was centrifuged at 8000r / min for 10min, washed with deionized water and absolute ethanol three times, and dried overnight at 80°C in air;

[0051] (3) The product prepared by the former was introduced into an alumina crucible with a cover, and then heated to 550° C. in a muffle furnace at a heating rate of 2° C. / min, and kept for 4 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com