Preparation method and device of translucent self-healing concrete

A concrete and self-repairing technology, which is applied in the field of concrete, can solve problems such as affecting the artistic effect of light-transmitting concrete, reducing product value, and difficult to control precision, so as to meet the needs of industrialized modular production, efficiently and accurately deploy construction, and ensure artistic decoration effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

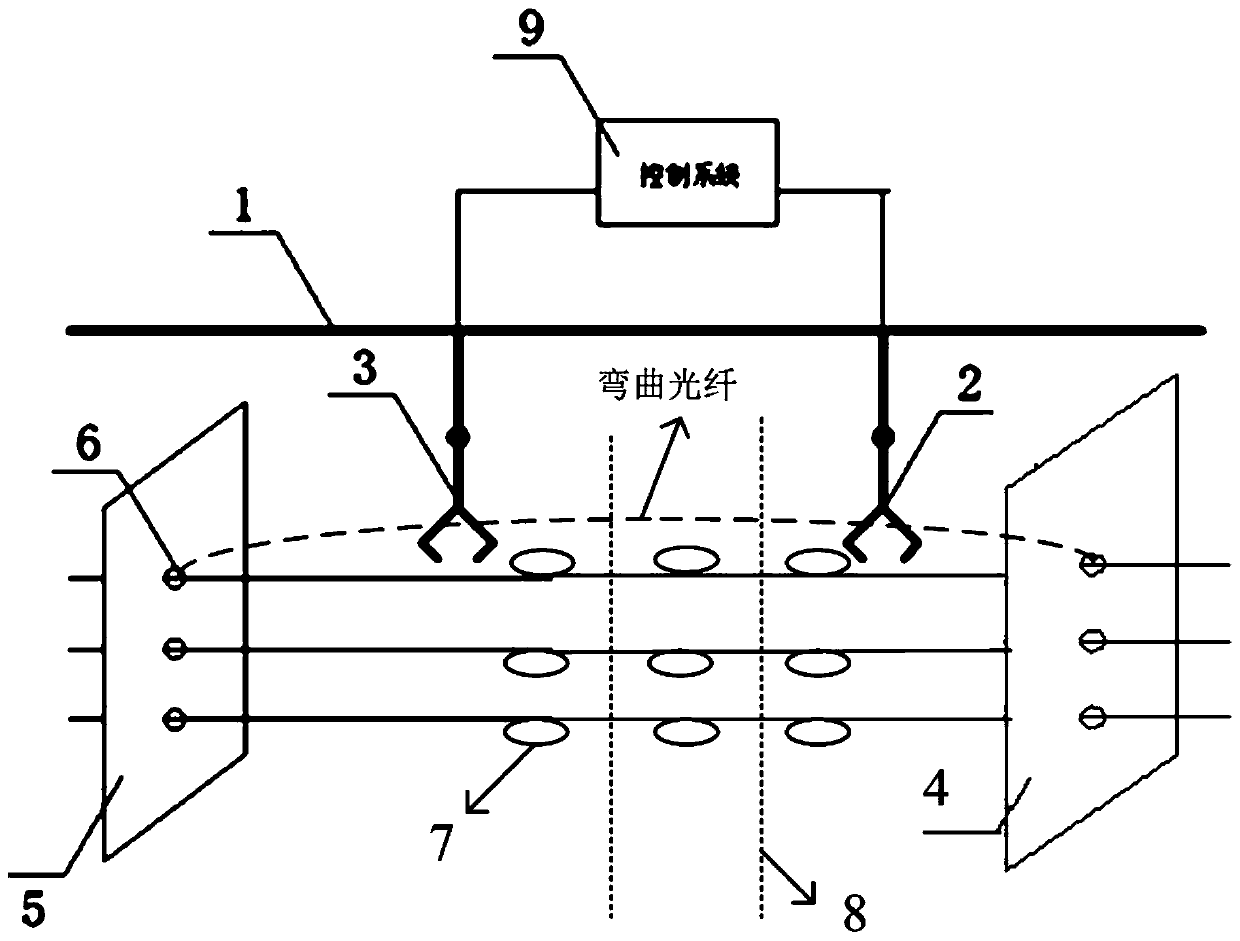

[0032] Combine below figure 1 , detailing the preparation method and device of the light-transmitting self-healing concrete of the present invention.

[0033] A method for preparing light-transmitting self-repairing concrete, comprising:

[0034] Step 1. Paste the self-repairing material 7 on the optical fiber, keep a certain distance between adjacent self-repairing materials 7, and the concrete cutting surface 8 is located within the distance;

[0035] Step 2. According to the layout design drawing of the optical fiber in the concrete, and use the control system 9 to control, wherein, the control system 9 includes a coordinate parameter control system, a bending control system and a motion equation control system, and the optical fiber coordinate parameter control system is set Determine the coordinates of the starting point and end point of the fixture; set the bending angle of the optical fiber in the optical fiber bending control system; set the horizontal and vertical mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com