Turnover device of vehicle-mounted display

A vehicle-mounted display and flipping device technology, which is applied to vehicle parts, transportation and packaging, can solve the problems of display board and flat frame acceleration impact, worm gear damage, etc., and achieve improved reliability, improved service life, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

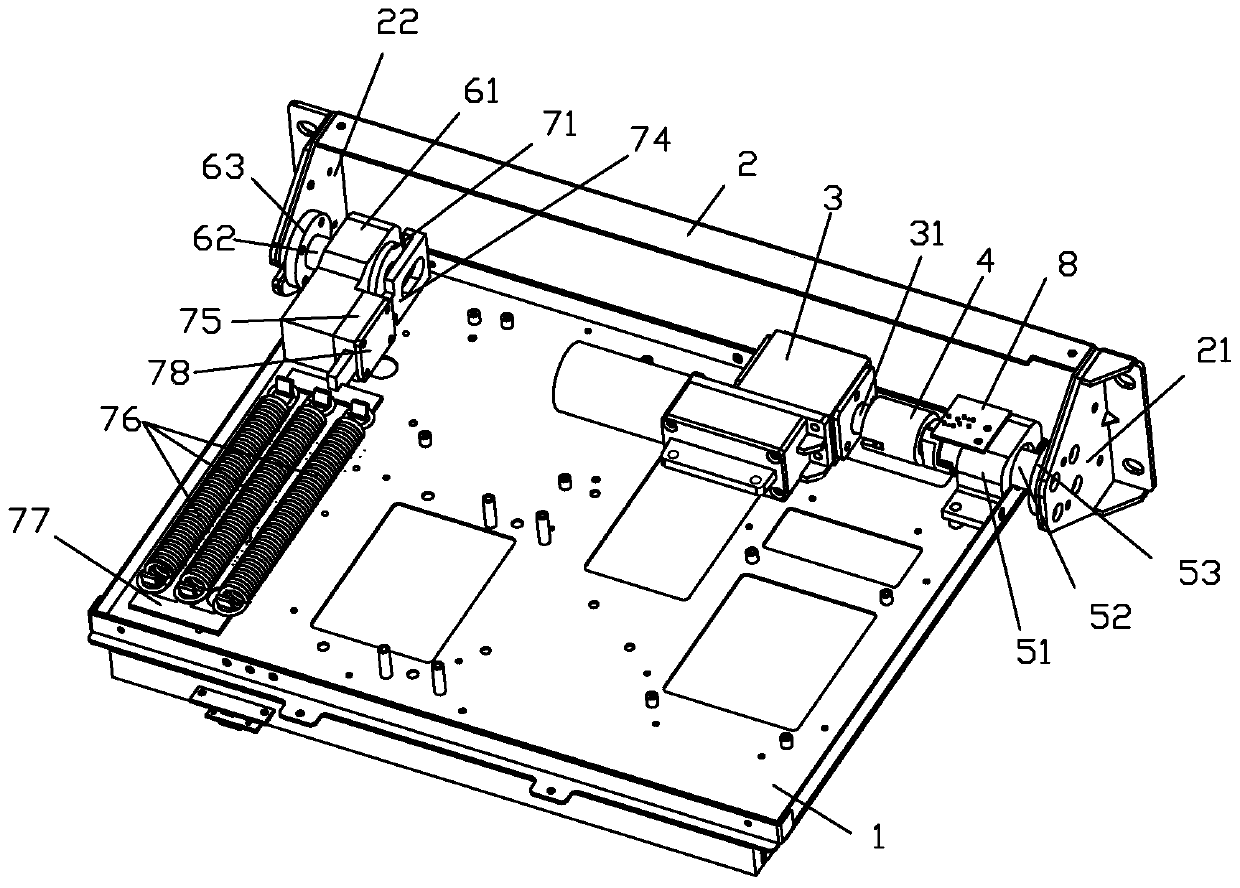

[0064] For the overturning device of the vehicle-mounted display of embodiment one, please refer to figure 1 . The overturning device includes a connecting frame and a mounting frame 2, and the connecting frame is, for example, a flat frame 1. Tablet 1 and display panel ( figure 1 Not shown in ) is connected to the back, the connection is fixed.

[0065] Mounting frame 2 is fixed on the car roof, and its left and right ends are respectively provided with the right lug 21 and the left lug 22 that protrude downwards. On the flat frame 1, a side near the mounting frame 2 is fixedly installed with a left rotating frame part, a driving mechanism and a right rotating frame part in sequence, the left rotating frame part includes a left rotating frame 61, and the right rotating frame part includes a right rotating frame 51.

[0066] The driving mechanism is mounted on the connecting frame and connected to the mounting frame 2 through transmission. If the driving mechanism includes ...

Embodiment 2

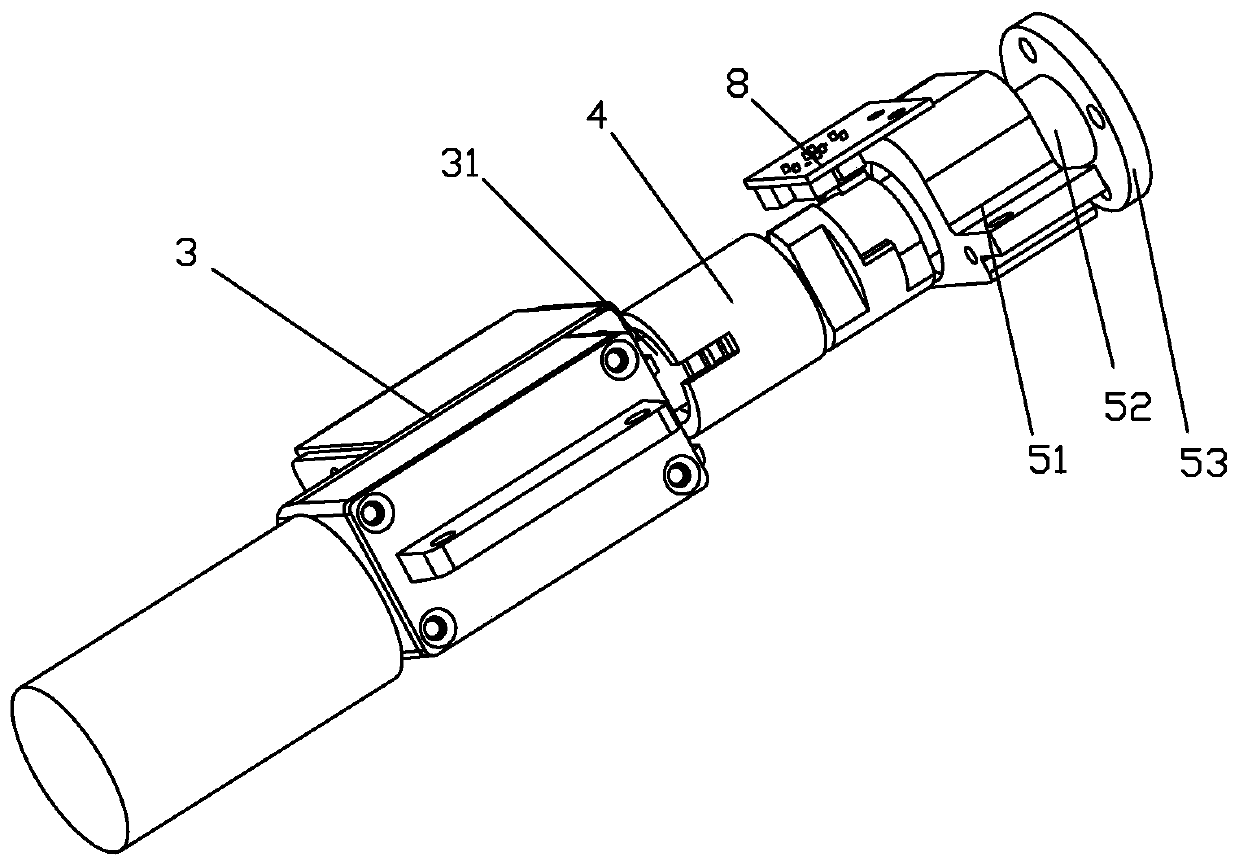

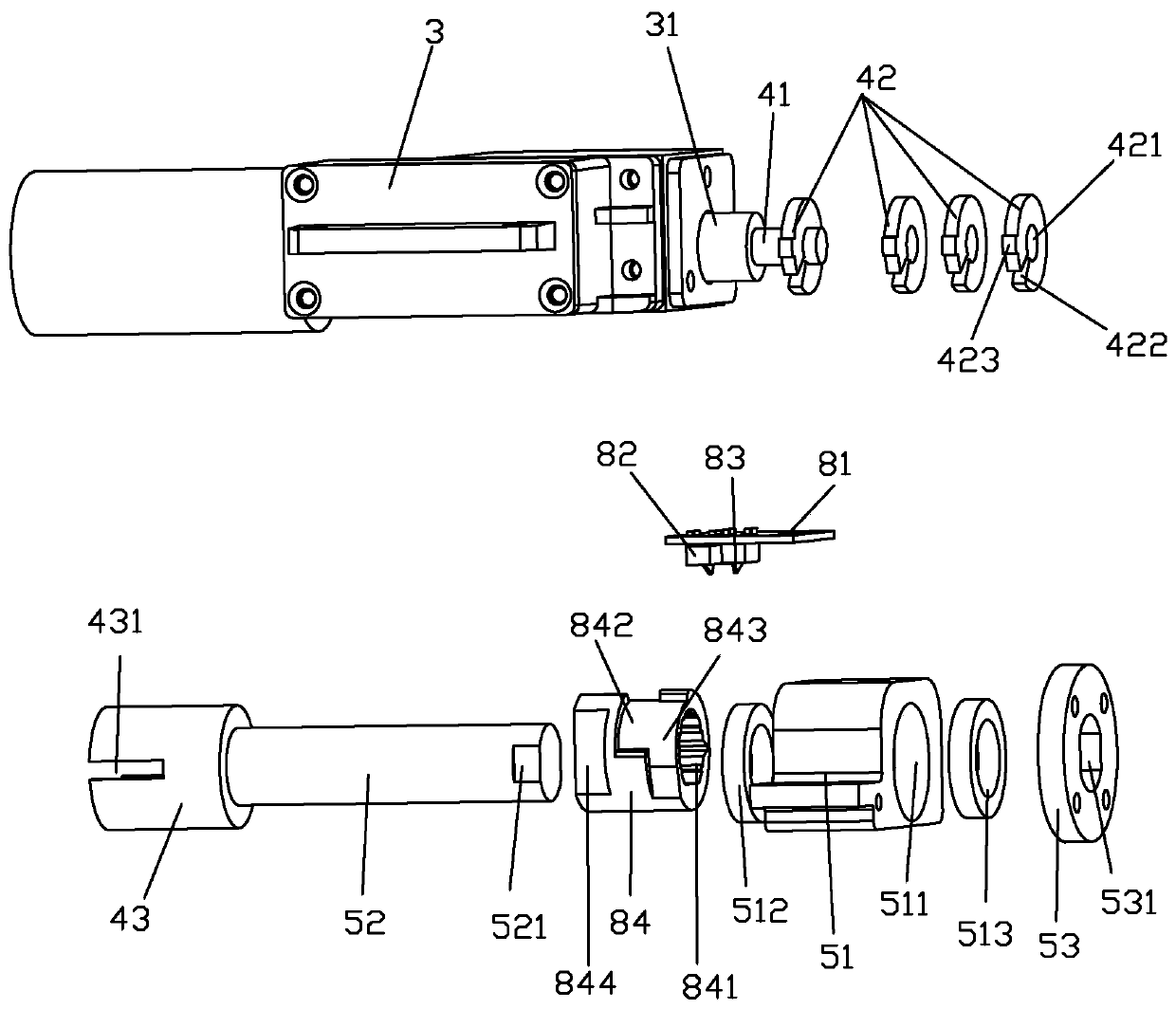

[0083] For the structure of the turning device of the vehicle-mounted display of embodiment two, please refer to Figure 7 . The overturning device has a connecting frame and a mounting frame 2, and the connecting frame includes a flat frame 1. Tablet 1 and display panel ( Figure 7 not shown in the back) connected to the back. Mounting frame 2 is fixed on the car roof, and its left and right ends are respectively provided with the right lug 21 and the left lug 22 that protrude downwards. One side near the mounting frame 2 on the flat frame 1 is fixedly installed with a left rotating frame part, a driving mechanism and a right rotating frame part in sequence, the left rotating frame part includes a left rotating frame 61, and the right rotating frame part includes a right rotating frame 51.

[0084] The drive mechanism includes a geared motor 3 , and the output shaft 31 of the geared motor 3 is coaxially connected to a right fixed shaft 52 sleeved on a right rotating frame ...

Embodiment 3

[0093] It differs from the structure of the turning device of the vehicle-mounted display in Embodiment 1 in that:

[0094] Please see Figure 10 , the driving mechanism and the gravity balance mechanism are respectively arranged on both sides of the flat frame 1, such as being respectively located on the right side and the left side, thereby reducing the thickness of the flat frame, making the combined thickness of the display and the flat frame thinner, reasonable layout, and compact structure. The driving mechanism is fixedly installed on the right side of the mounting frame 2, for example, it can be fixedly mounted on the mounting frame 2 ( Figure 10 (not shown in the middle) on the right lug, or directly fixedly installed on the mounting frame 2. The driving mechanism is connected to the flat frame 1 through transmission to drive the flat frame 1 to rotate around the rotating shaft. As required, the drive mechanism includes a motor 3 with a built-in clutch and a drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com