A kind of tubular nickel electrode for alkaline battery and preparation method thereof

An alkaline battery and nickel electrode technology, which is applied in the field of tubular nickel electrodes for alkaline batteries and their preparation, can solve the problems of small surface capacity of nickel electrodes, shedding of active materials, damage to electrode life, etc., and achieves the total battery capacity. Large, low cost, prolong the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

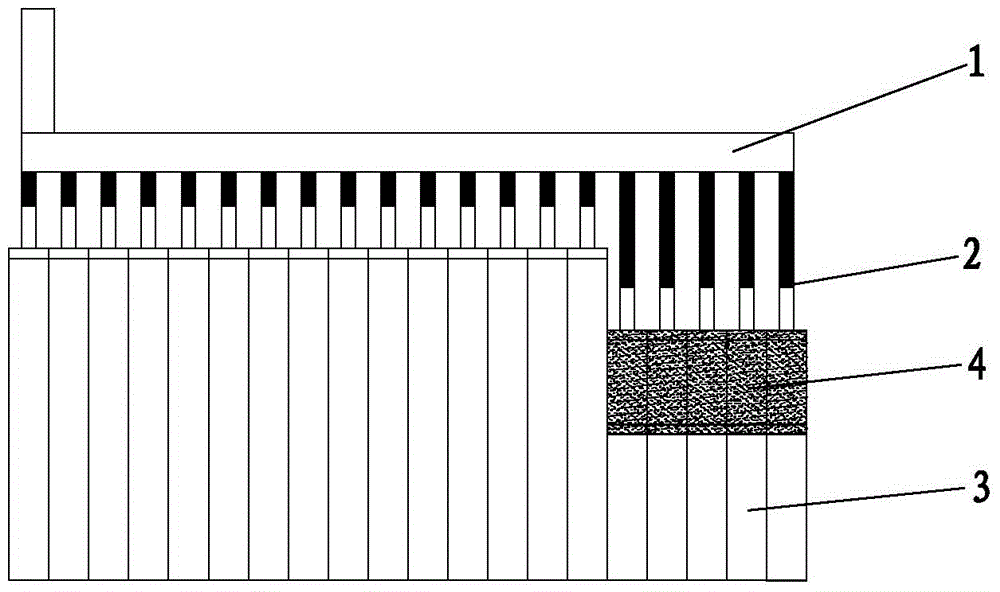

[0032] Such as figure 1 As shown, the tubular nickel electrode for alkaline battery of the present invention comprises 19 diameters of 4.5mm and a length of 70mm porous circular nickel foam strips as the conductive base core 2, which is connected to one end of the conductive base core 2 The collector electrode 1, the material of the collector electrode 1 is nickel-plated stainless steel, the conductive base core 2 is provided with the same number of conductive base cores with a length of 70 mm, an inner diameter of 5 mm, and a circular pipe 3 with a wall thickness of 0.5 mm. The row pipe 3 is braided by nylon silk and cured by a curing agent. The porosity of the row pipe 3 is 50%, and the braided aperture is 50 microns. One end of the row pipe 3 is closed by a polyethylene plastic button with an outer diameter of 5 mm. The other end is in contact with the collector electrode 1, and the contact part between the collector electrode 1 and the row pipe 3 is a low round platform...

Embodiment 2

[0035] A tubular nickel electrode for an alkaline battery, comprising 10 nickel-plated steel pipes with a length of 100 mm, an outer diameter of 4.5 mm, and a wall thickness of 0.5 mm as a conductive base core 2, and a collector electrode integrated with one end of the conductive base core 2 1. The collector 1 is a concave nickel-plated steel sheet with a length of 100 mm and a width of 20 mm. The conductive base core 2 is provided with the same number of conductive base cores with a length of 105 mm, an inner diameter of 5 mm, and a wall thickness of 0.4 mm. Shaped pipe 3, the pipe 3 is braided by polypropylene silk and solidified by a curing agent, the porosity of the pipe 3 is 55%, the diameter of the braided hole is 50 microns, and one end of the pipe 3 is made of polyethylene with an outer diameter of 5 mm. Alcohol plastic buckle bottom is closed, the offset part of the collector 1 and the row pipe 3 is a low round table with an outer diameter of 5mm to seal the row pipe...

Embodiment 3

[0038] A tubular nickel electrode for an alkaline battery, comprising 38 hollow square nickel-plated stainless steel posts with a length of 250 mm and a side length of 5.5 cm as a conductive base core 2, a collector electrode 1 welded to one end of the conductive base core 2, and The electrode 1 is made of nickel-plated stainless steel, and the conductive base core 2 is provided with the same number of circular tubes 3 with a length of 250 mm, an inner diameter of 6 mm, and a wall thickness of 0.5 mm. Vinylidene fluoride is braided and solidified by a curing agent. The porosity of the row pipe 3 is 55%, and the braided aperture is 45 microns. One end of the row pipe 3 is closed by a polyvinyl chloride plastic buckle bottom with an outer diameter of 6mm. The offset part between 1 and row pipe 3 is a low round platform with an outer diameter of 6mm to seal row pipe 3, and the gap between conductive base core 2 and row pipe 3 is filled with uniformly mixed nickel electrode slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com