A film-coated nickel electrode for alkaline storage battery and preparation method thereof

A technology for nickel electrodes and storage batteries, applied in the field of film-coated nickel electrodes for alkaline storage batteries and its preparation, can solve the problems of high production cost of nickel electrodes, shedding of active materials, short cycle life, etc., and improve specific capacity and utilization rate , Coating thickness increases, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The following is an embodiment of the film-coated nickel electrode for alkaline accumulator of the present invention, the structure and the method of making are as described above, and the specific implementation details are as follows:

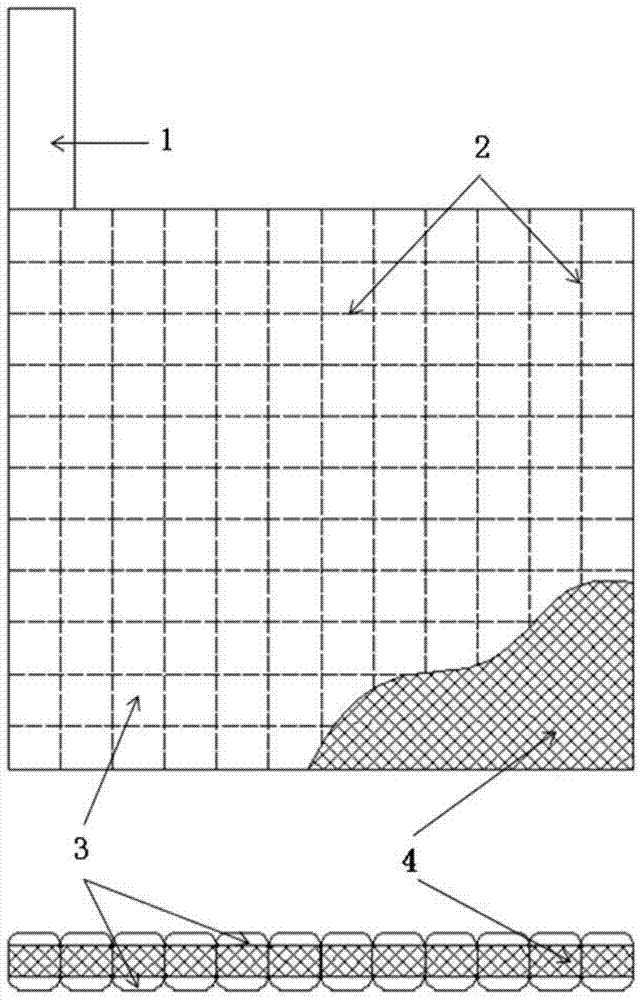

[0046] With the foamed nickel sheet of porous loose structure as the conductive matrix, each component (according to mass fraction) in the described nickel electrode slurry is: nickel hydroxide 34%, nickel powder 34%, cobalt oxide 5%, water 25%, CMC 0.7% and PTFE 1.3%. The alkali-resistant diaphragm 3 is a modified PP non-woven fabric, and the nylon fiber filament with a diameter of 0.5 mm is used as the suture 2 to sew the alkali-resistant diaphragm 3 and the sheet nickel electrode 4 into one body.

Embodiment 2

[0048] The following is an embodiment of the film-coated nickel electrode for alkaline accumulator of the present invention. The structure and manufacturing method are referred to above, and the specific implementation details are as follows:

[0049] With a plurality of (more than 2) foamed nickel sheets of porous and loose structure as the conductive matrix, each component (according to mass fraction) in the nickel electrode slurry is: 50% of cobalt-coated nickel hydroxide, 30% of nickel powder, Toner 3%, Absolute Alcohol 15%, Polyvinyl Alcohol 1%, and PTFE 1%. After rolling, cutting, welding and shaping, the sheet-shaped nickel foam electrode is produced. The alkali-resistant diaphragm 3 is nylon woven cloth, and the alkali-resistant fiber filament with a diameter of 0.2 mm is used as the suture 2 to sew the alkali-resistant diaphragm 3 and the sheet-shaped nickel electrode 4 into one body. Finally, the alkali-resistant sealing material 704 (vulcanized silicone rubber) is ...

Embodiment 3

[0052] The following is an embodiment of the film-coated nickel electrode for alkaline accumulator of the present invention. The structure and manufacturing method are referred to above, and the specific implementation details are as follows:

[0053] The foamed nickel sheet with a porous and loose structure is used as a conductive matrix, and the components (according to mass fraction) in the nickel electrode slurry are: 55% of cobalt-coated nickel hydroxide, 30% of nickel powder, 12% of distilled water, and 1% of CMC and PTFE 2%. After rolling, the active material slurry is loaded again for secondary rolling. After drying and shaping, a bare electrode chip (that is, a sheet-shaped nickel electrode 4) is obtained. The alkali-resistant diaphragm 3 is a polyethylene woven cloth, and a nylon wire with a diameter of 0.3 mm is used as the suture 2 to sew the alkali-resistant diaphragm 3 and the sheet nickel electrode 4 into one body. Finally, the alkali-resistant asphalt dots ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com