Automatic car washer

A car washing machine and automatic technology, which is applied in the field of vehicle cleaning, can solve the problems of time-consuming and laborious, cumbersome disassembly and assembly process, and achieve the effects of ensuring stability, quick disassembly, improving disassembly and assembly efficiency and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

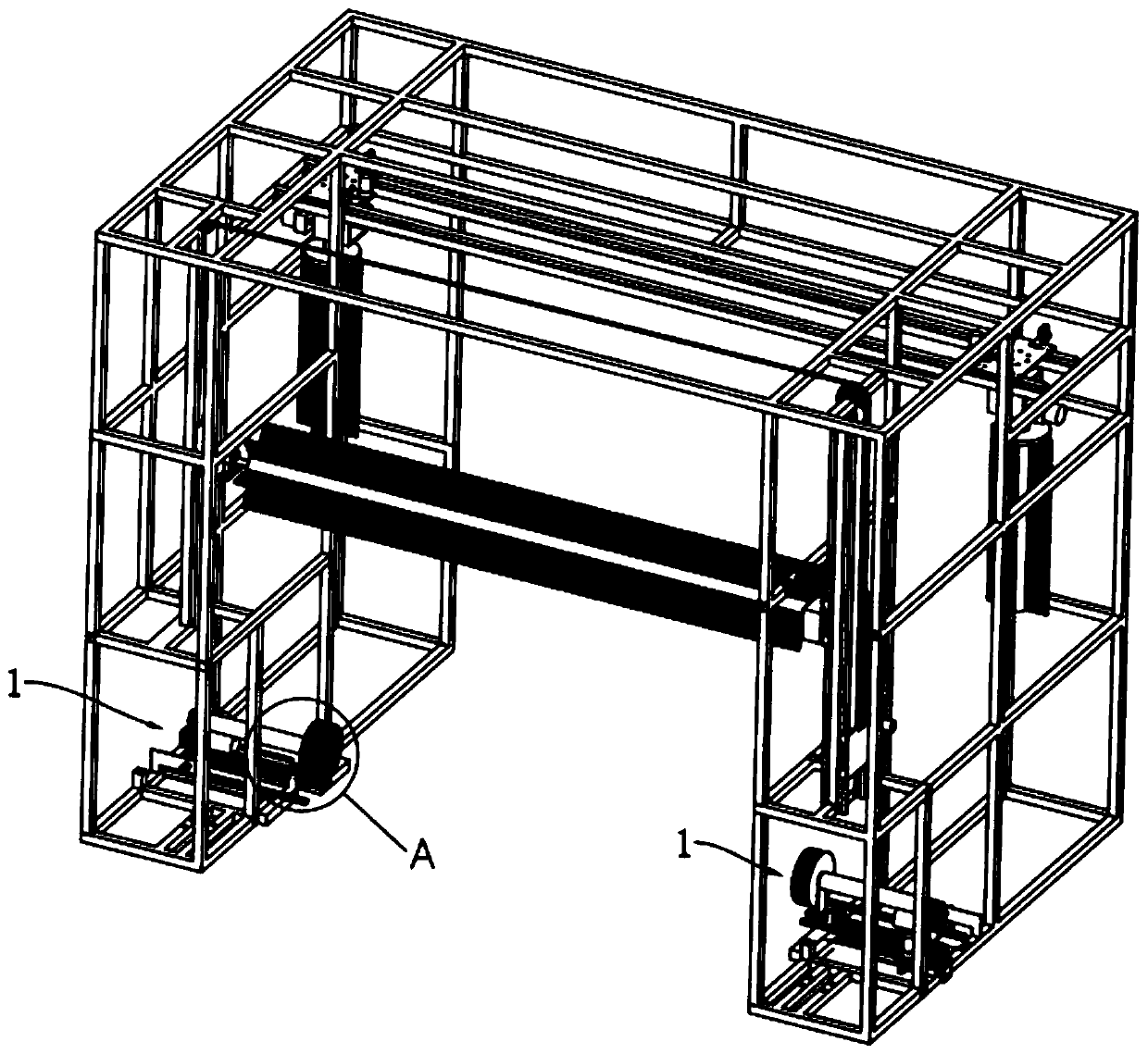

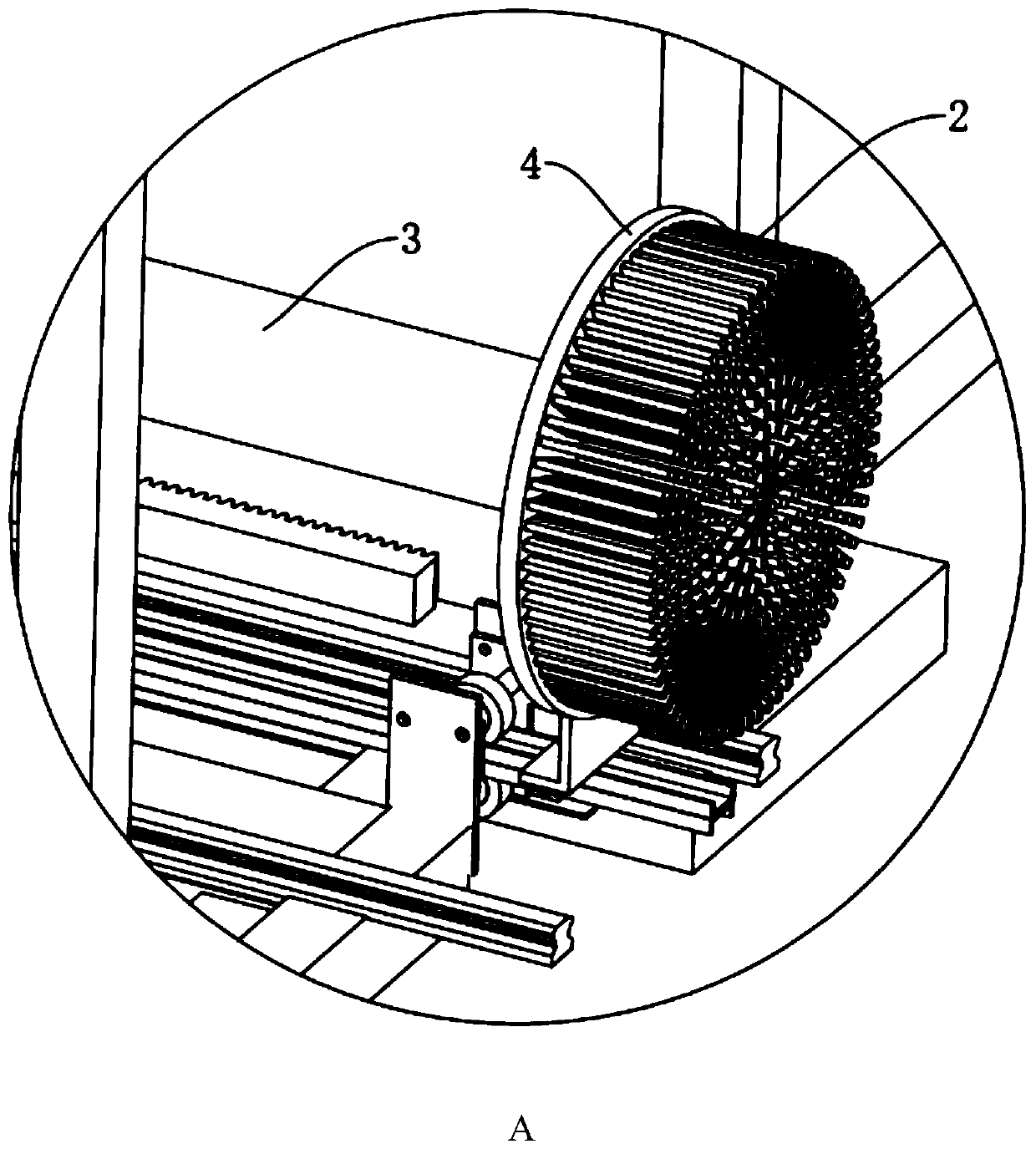

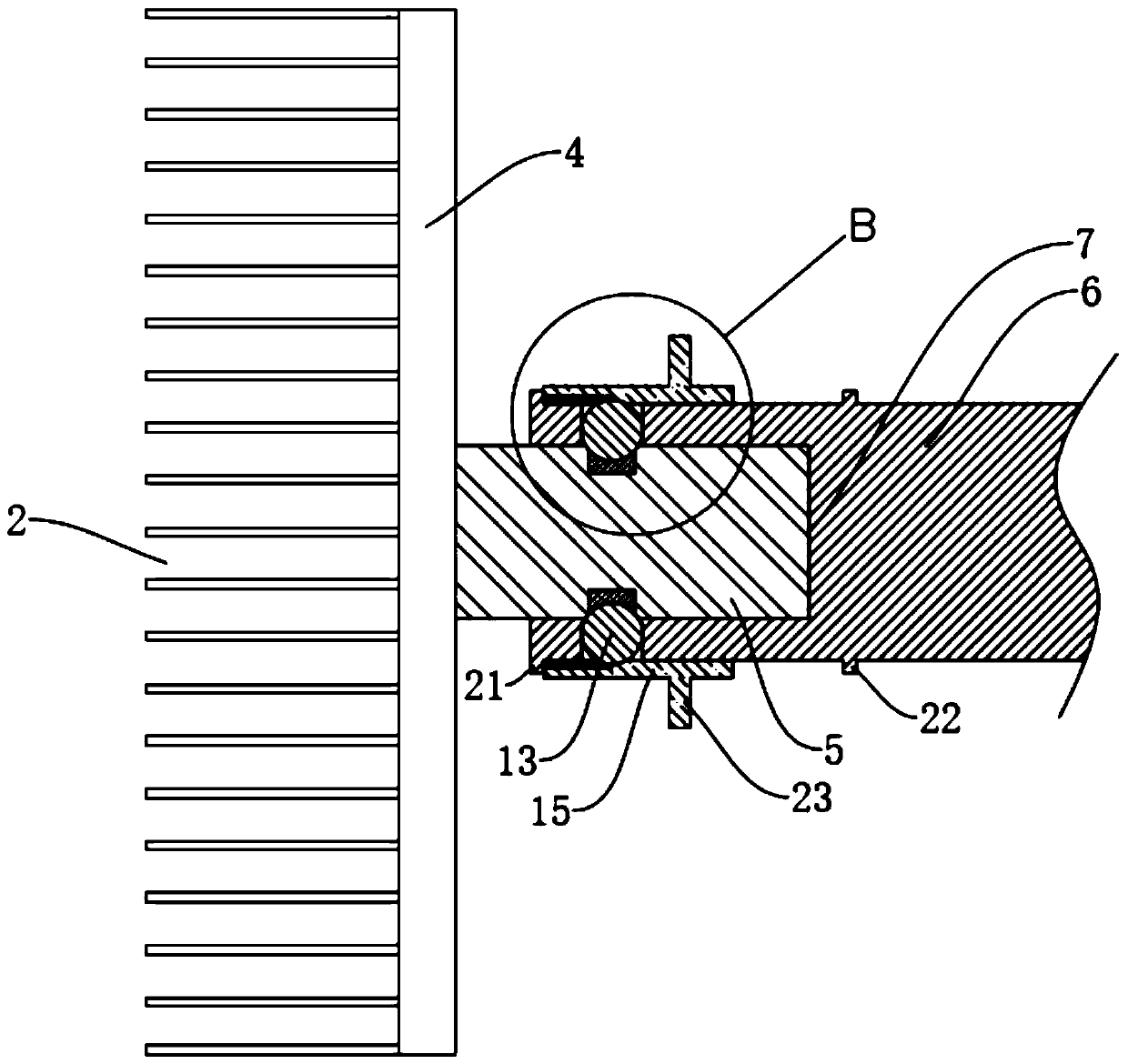

[0021] Such as Figure 1 to Figure 5 As shown, an automatic car washing machine disclosed in this embodiment includes a wheel brush system 1. The wheel brush system 1 includes a wheel brush 2 and a drive motor 3. A connecting shaft 5 extends vertically from the center of the chassis 4 of the wheel brush 2. The connecting shaft 5 is preferably cylindrical. The end face of the output shaft 6 of the drive motor 3 is provided with a slot 7 for connecting the connecting shaft 5. The slot 7 is preferably cylindrical, and its internal space size is adapted to the size of the connecting shaft 5, so that the connecting shaft 5 can be connected with the plugging shaft. Groove 7 is a tight fit. The outer wall of the connecting shaft 5 is provided with an outer limit plane 8 along its length direction, and the inner wall of the slot 7 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com