A Calculation Method of Axle Load of Articulated Three-axle Bus

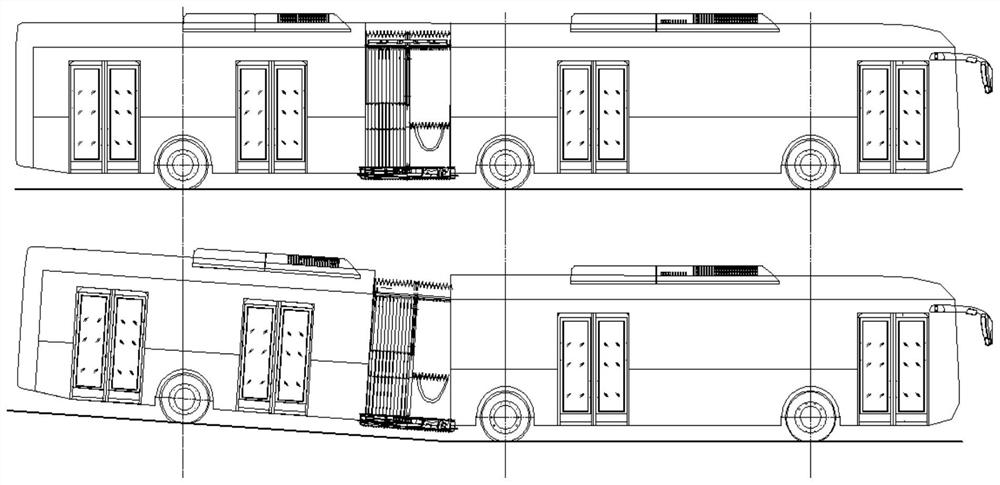

A calculation method and articulated technology, applied in the field of mechanical measurement, can solve the problem of lack of axle load calculation method, and achieve the effect of solving uneven axle load distribution, reducing design changes, and optimizing axle load distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

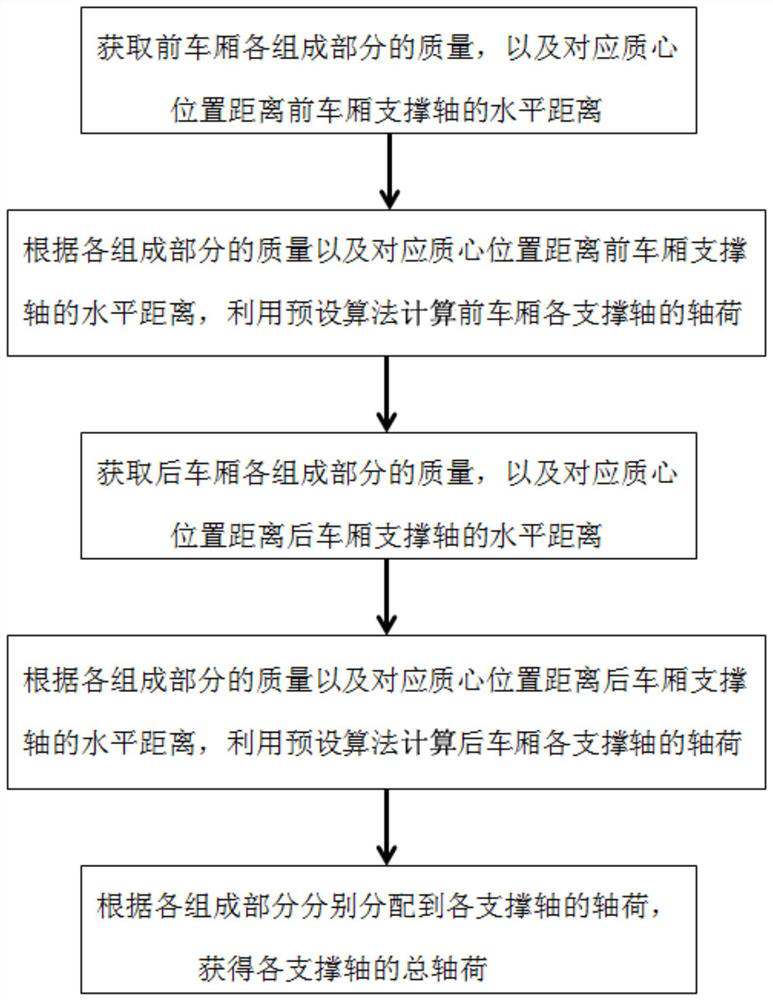

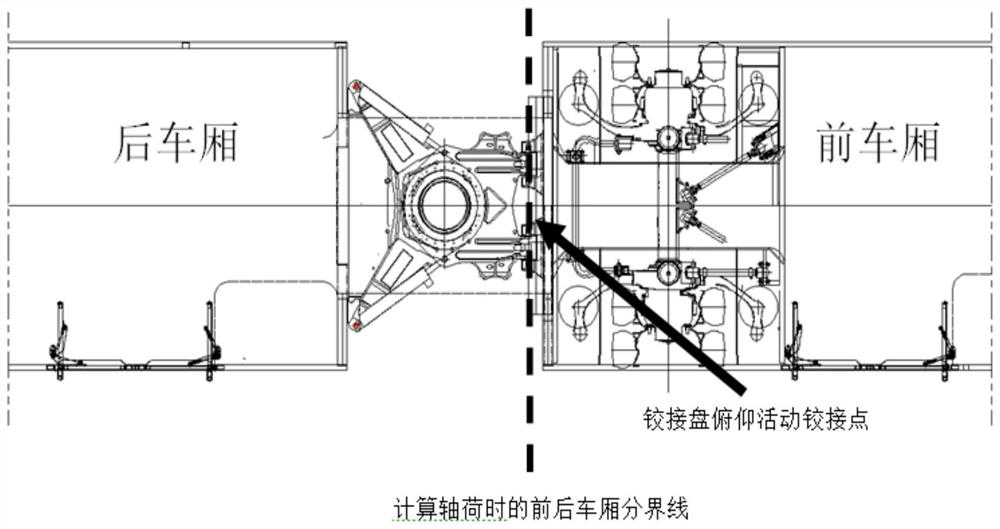

[0046] Such as figure 1 As shown, a method for calculating the axle load of an articulated three-axle passenger car includes the following steps:

[0047] S1: Obtain the mass of each component of the front carriage, and the horizontal distance from the corresponding centroid position to the support axis of the front carriage;

[0048] S2: According to the mass of each component and the horizontal distance from the corresponding centroid position to the support shaft of the front car, use the preset algorithm to calculate the axle load of each support shaft of the front car;

[0049] S3: Obtain the mass of each component of the rear compartment, and the horizontal distance from the position of the corresponding center of mass to the support shaft of the rear compartment;

[0050] S4: According to the mass of each component and the horizontal distance from the corresponding centroid position to the support shaft of the rear compartment, the axle load of each support shaft of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com