Photoluminescent lubricating grease composition, photoluminescent material and preparation methods thereof

A technology of compounds and derivatives, applied in the field of photoluminescent materials, can solve the problems such as the difficulty of grease monitoring, observation, and difficulty in the remaining amount of grease.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

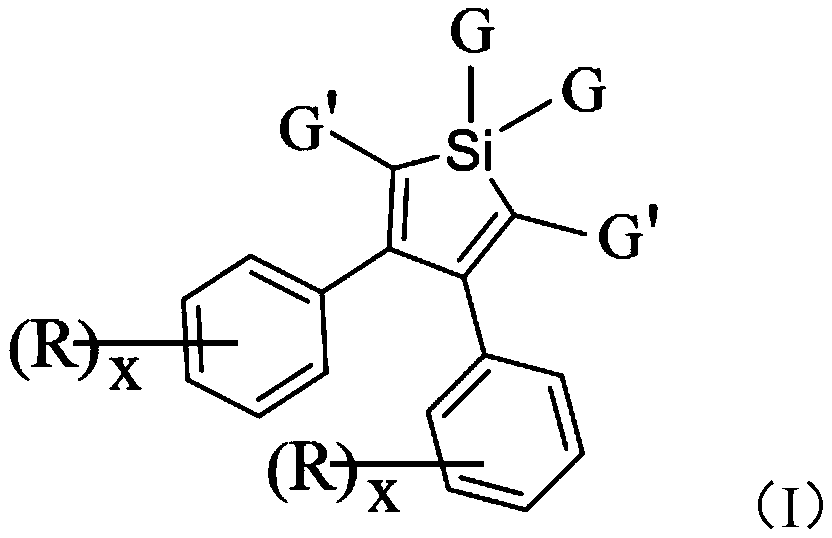

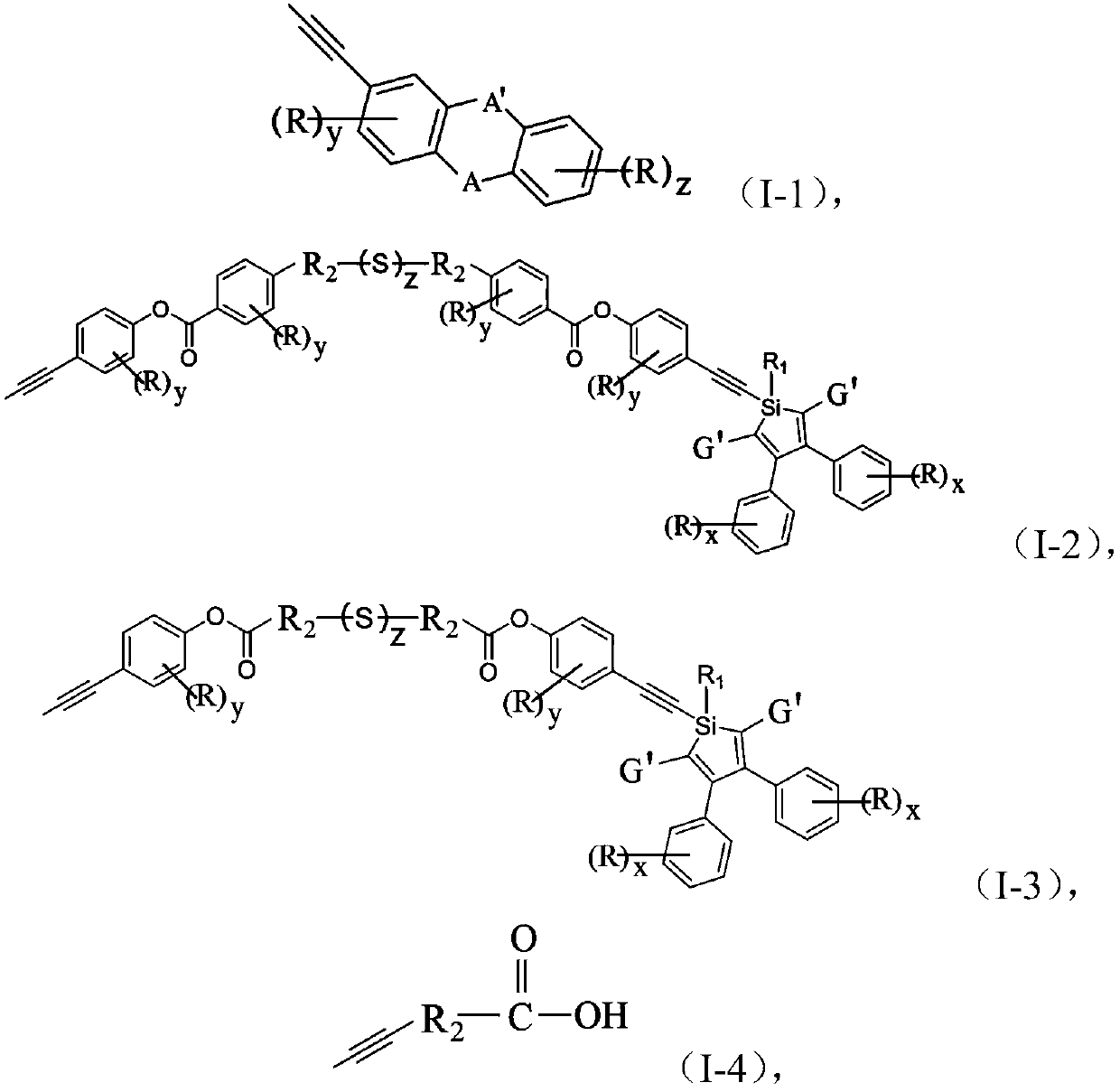

[0085] The present invention provides the first preparation method of the silole derivatives with the general formula (I), comprising: making the silole compound shown in the general formula (III-1) and the general formula (III-1′), ( A step in which one or more alkyne compounds shown in III-2'), (III-3'), (III-4'), (III-5') and (III-6') react,

[0086]

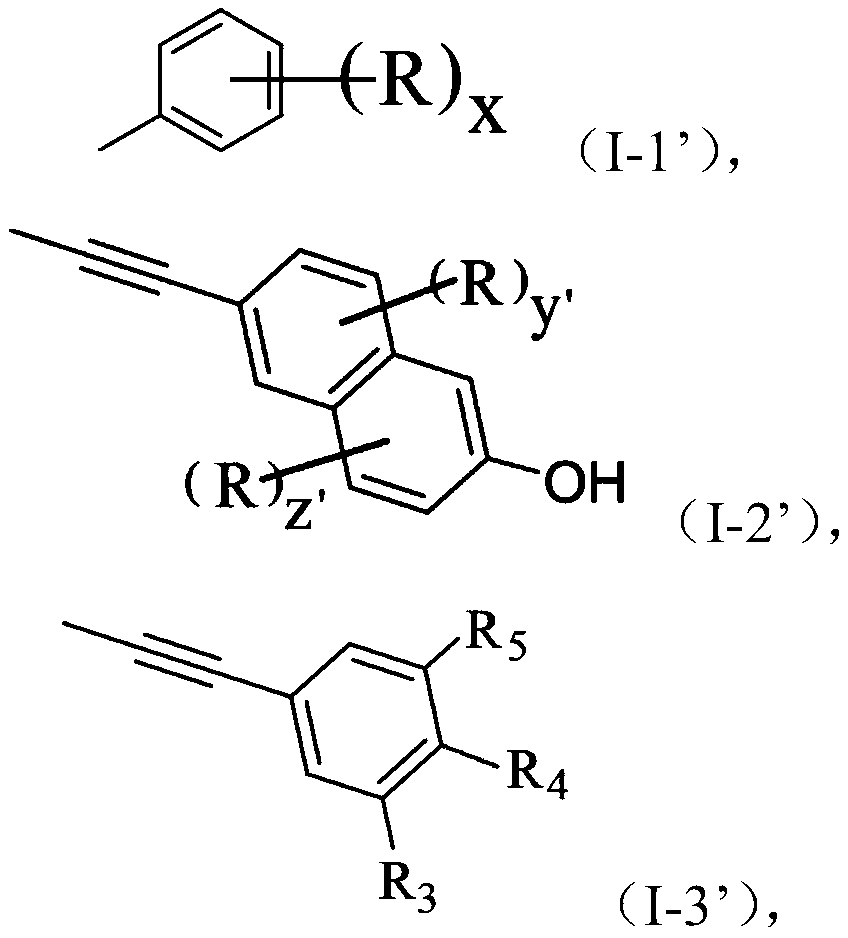

[0087] In the general formula (III-1), each R is independently selected from hydrogen, C 1-6 Straight chain or branched chain alkyl, each x is independently selected from integers between 0-5; each G is independently selected from hydrogen, C 1-6 Straight chain or branched chain alkyl, the group shown in formula (I-1 '), X group; Each G' is independently selected from hydrogen, C 1-6 Straight chain or branched chain alkyl, the group shown in formula (I-1 '), X group;

[0088]

[0089] In formula (I-1'), each R is independently selected from hydrogen, C 1-6 Straight-chain or branched-chain alkyl; each x is independent...

Embodiment

[0152] The following examples will further illustrate the present disclosure, but do not limit the present disclosure thereby.

no. 1 approach

[0154] According to the first embodiment of the present invention, the structure of the silole derivative with general formula (I) is:

[0155]

[0156] In the general formula (I-I), each R is independently selected from hydrogen, C 1-6 Straight chain or branched chain alkyl, each n is independently selected from integers between 0-5; R 1 , R 2 The same or different from each other, each independently selected from hydrogen, C 1-6 Straight chain or branched chain alkyl; R 3 , R 4 , R 5 , R 3 ’, R 4 ’, R 5 ' are the same or different from each other, each independently selected from hydrogen, C 1-300 Straight chain or branched chain alkyl (preferably C 1-10 straight chain or branched chain alkyl or number average molecular weight Mn is the polyolefin base of 300-3000), the group shown in general formula (II-I), provided that R 3 , R 4 , R 5 In at least one group is the group shown in general formula (II-I), R 3 ’, R 4 ’, R 5 At least one group in ' is a group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com