Ultrahigh-performance concrete distributing apparatus and application method thereof

A material distributing device, ultra-high-performance technology, applied in the direction of measuring devices, height/level measurement, erection/assembly of bridges, etc., can solve problems such as difficult mixing and paving, uneven feeding, and the impact of continuous laying of concrete to achieve high efficiency The effect of operation and reduction of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

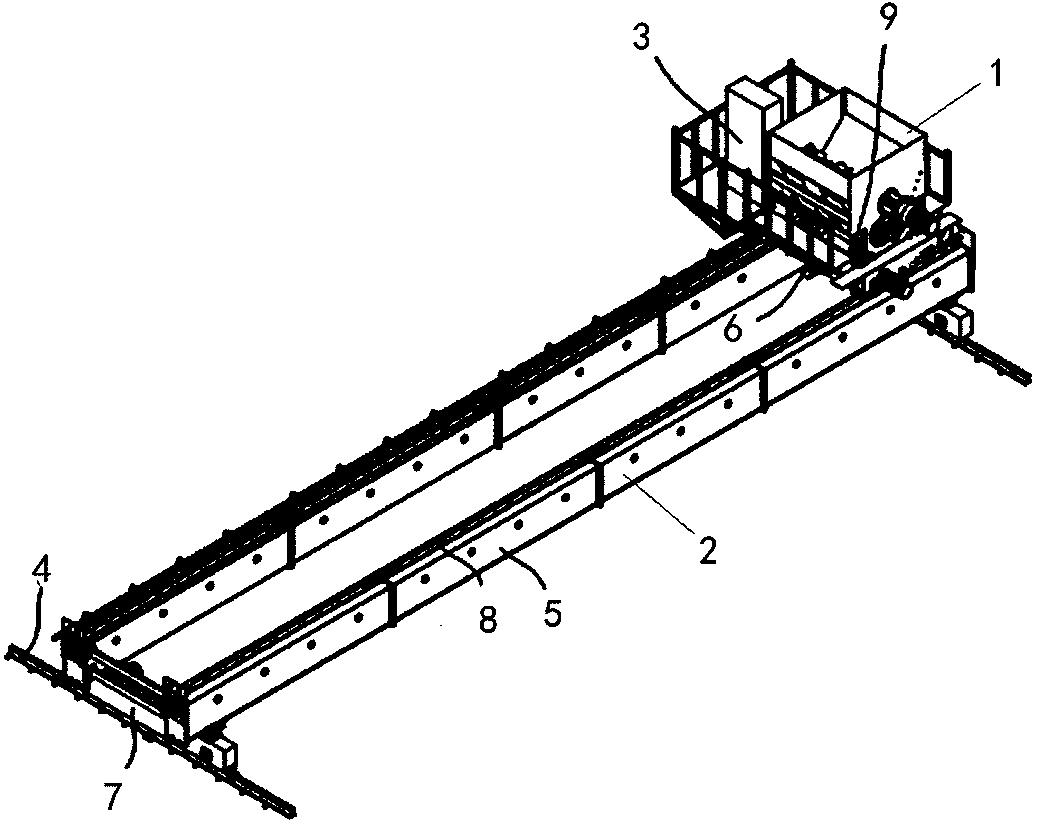

[0026] Example: such as figure 1 As shown, the ultra-high performance concrete distribution device in this embodiment includes a quantitative feeding device 1, a dynamic weighing device 8 for a silo, a translation device 2, and a distribution intelligent control device 3, wherein the quantitative feeding device 1 is set up on the translation device Upper 2, the quantitative unloading device 1 is mainly used to lay ultra-high performance concrete in the material distribution area, the translation device 2 is mainly used to drive the quantitative unloading device 1 to move in the material distribution area, and the dynamic weighing device 8 of the silo is connected to the quantitative lower Both sides of the lower end of the feeding device 1 are used to measure the stocking state and the decreasing value of the stocking material in the hopper of the quantitative feeding device 1. The quantitative feeding device 1 and the translation device 2 are under the control of the cloth int...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap