High pressure water pump

A high-pressure water pump and pump housing technology, applied in pump control, pump components, variable capacity pump components, etc., can solve the problems of unstable commutation, instability, affecting production efficiency, etc., to achieve compact size, space and parts saving , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

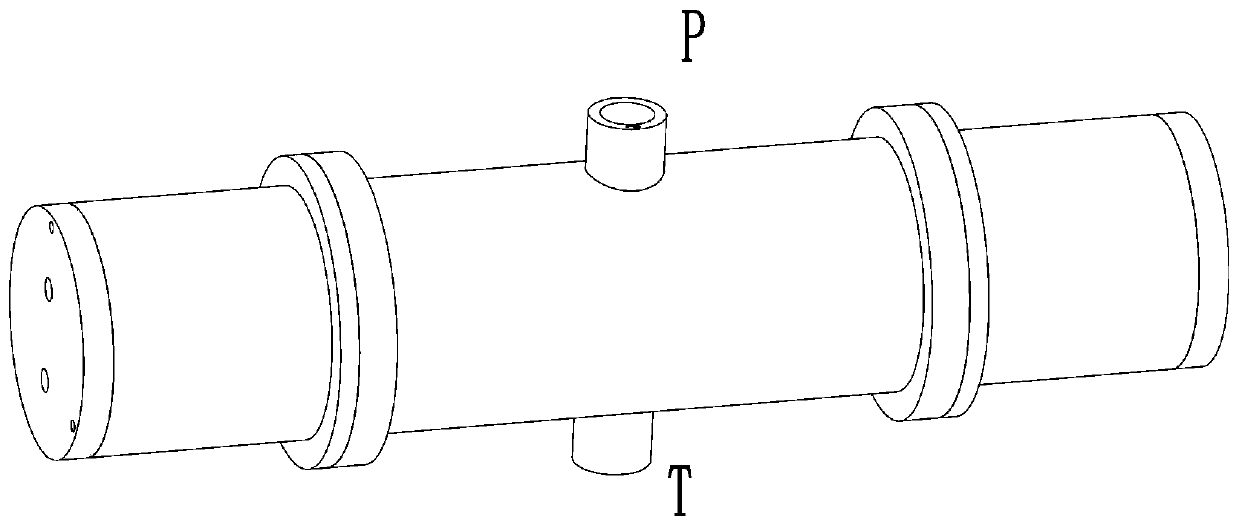

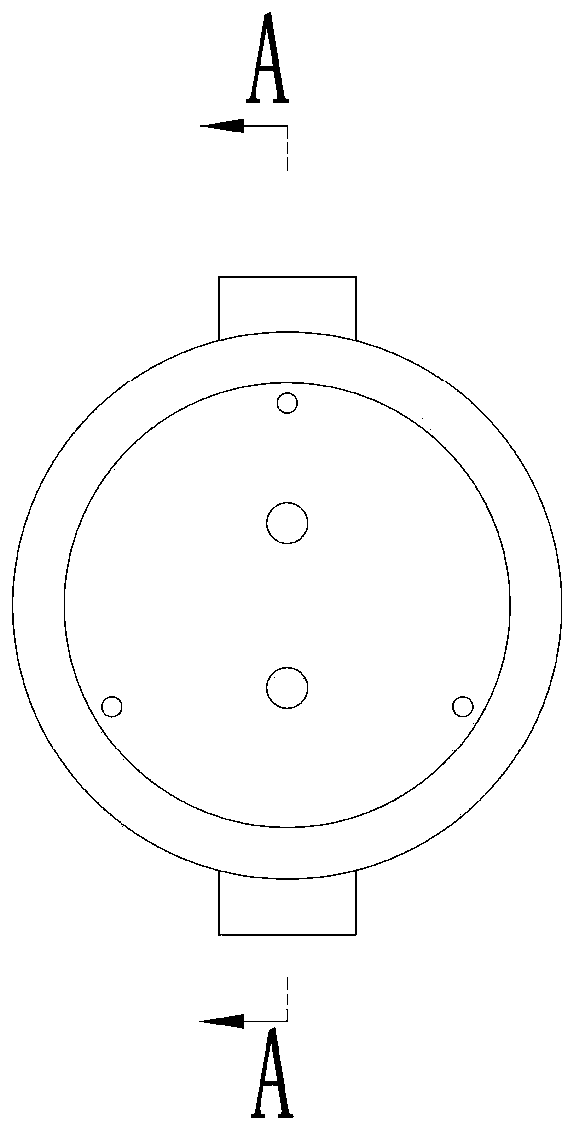

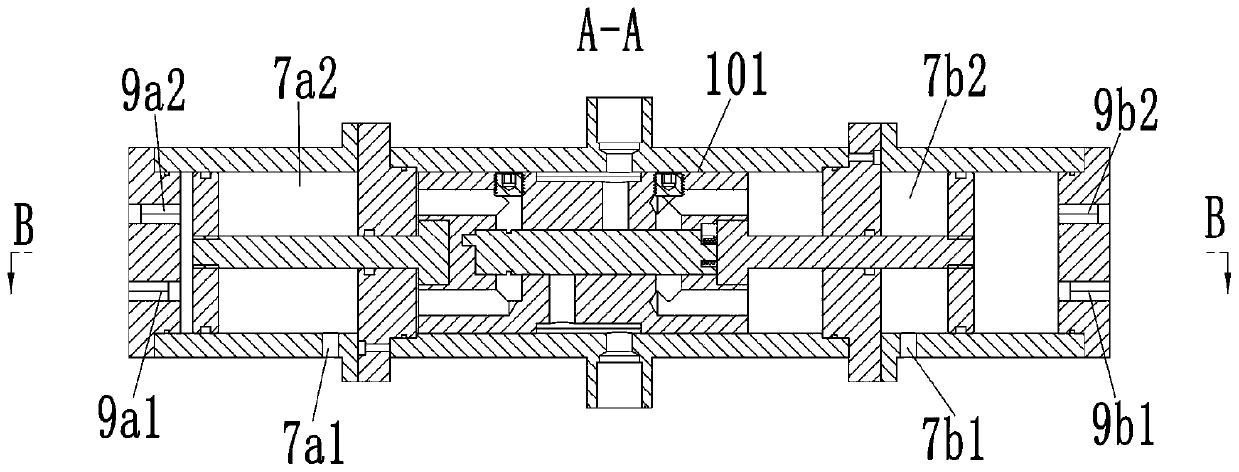

[0024] See Figure 1-23 As shown, a high-pressure water pump includes a pump body 1, which is provided with a left and right through mounting hole 101, a left end cover 6a is fixedly mounted on the left end of the pump body 1, and a right end cover 6b is fixedly mounted on the right end; A piston body 2 that moves left and right is slidingly connected to the mounting hole 101. A sliding guide hole 201 is provided on the piston body 2 along its movement direction. A sliding connection is provided between the left end cover 6a and the right end cover 6b. The anti-rotation guide slide bar 10 in the guide slide hole 201; a left pump casing 7a is fixedly installed on the left side of the left end cover 6a, and a left cover 9a is fixedly installed on the left end of the left pump casing 7a. A right pump casing 7b is fixedly installed on the right side of the right end cover 6b, and a right cover 9b is fixedly installed on the right end of the right pump casing 7b; the left end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com