Servo valve automatic centering device and method

An automatic centering and servo valve technology, applied in the field of servo valves, can solve the problems of low precision and low efficiency of manual centering of servo valves, achieve controllable accuracy, improve centering efficiency and precision, and save operating space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

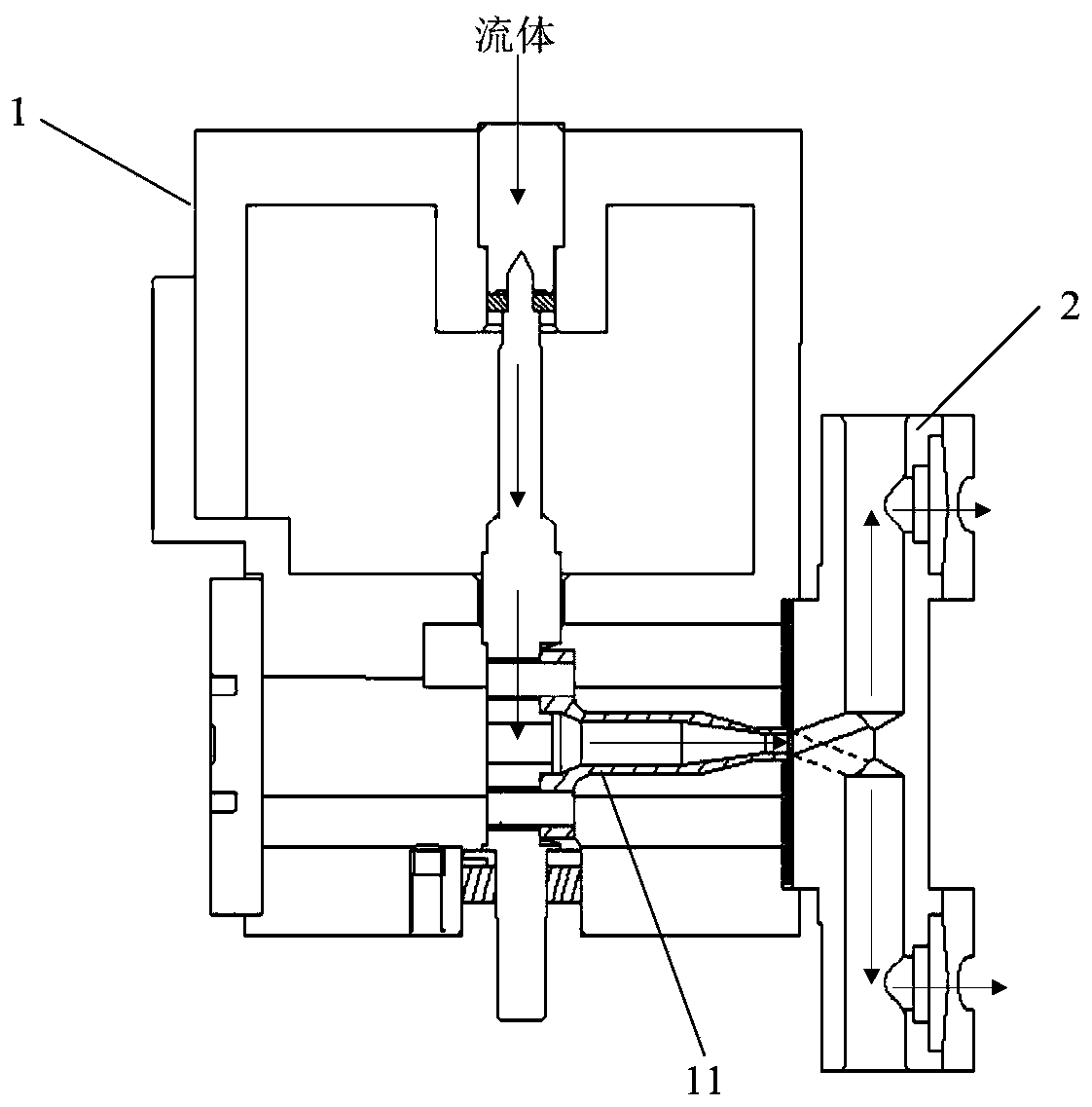

[0050] This embodiment provides an automatic centering device for a servo valve, which is used to feed air into the center of the valve 11 of the servo valve body 1 (the servo valve includes the servo valve body 1 and the receiver 2) and the two airflow channels of the receiver 2 The middle positions of the air inlets (hereinafter referred to as air inlet A and air inlet B) are aligned, and this process is referred to as valve centering.

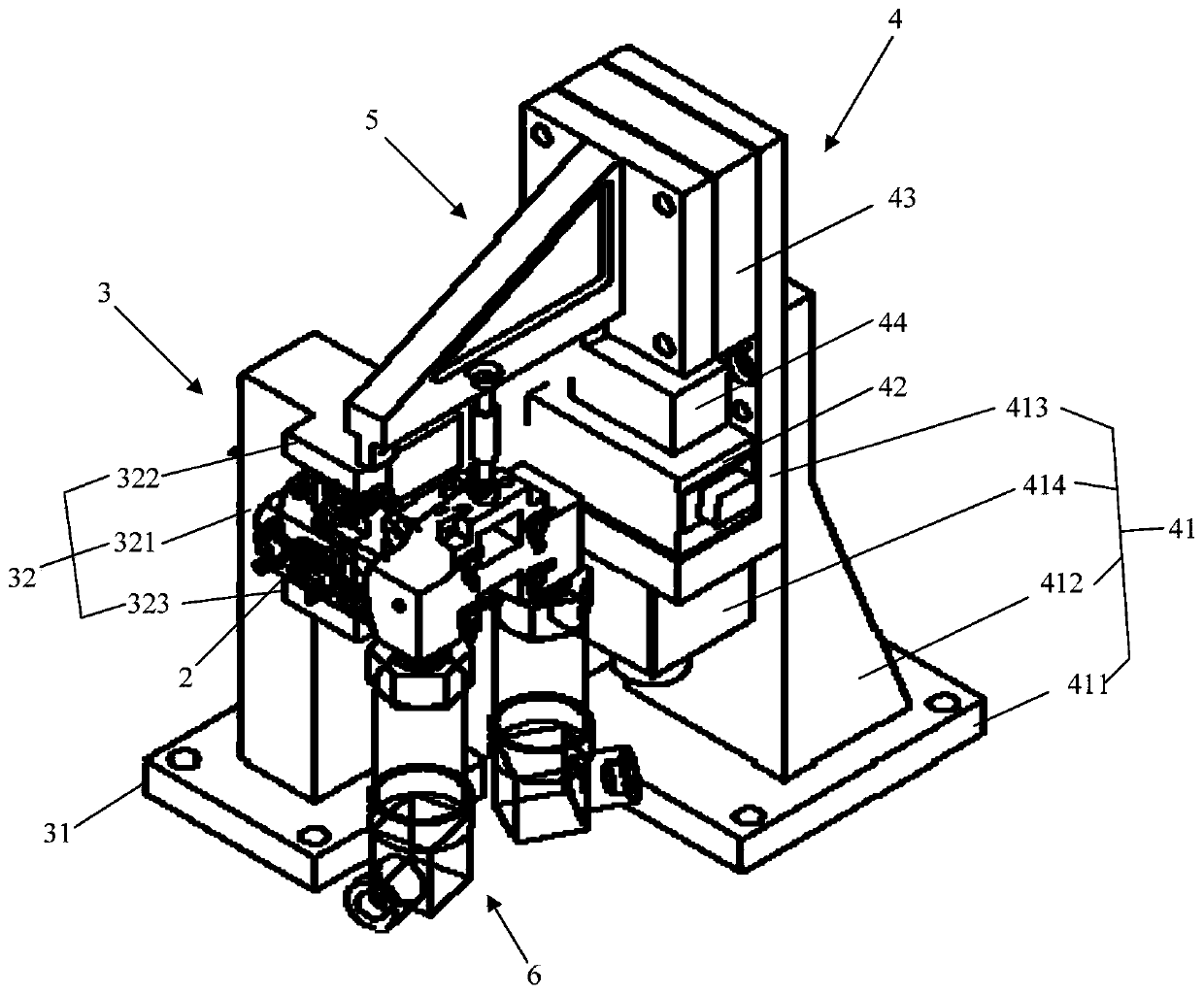

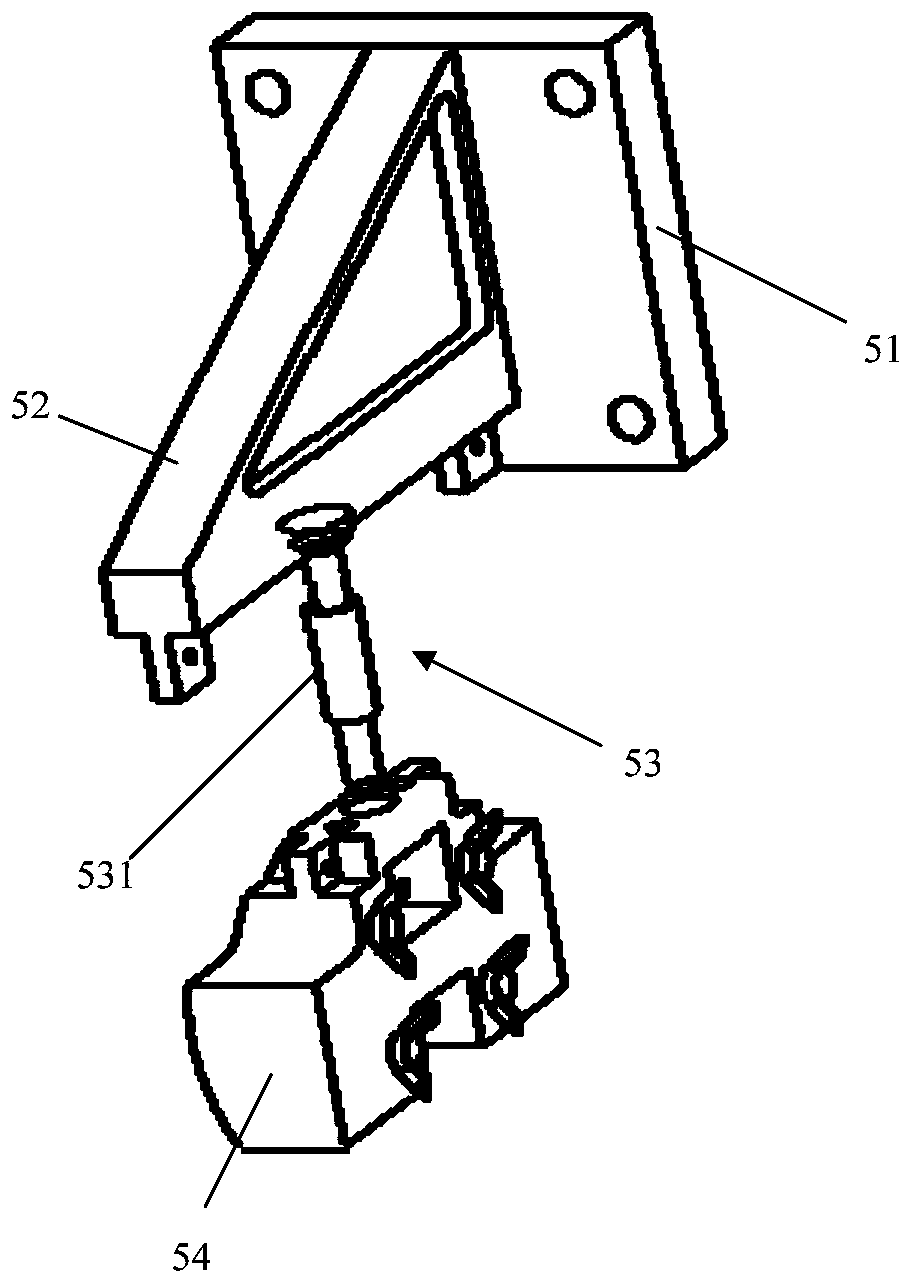

[0051] Such as Figure 1-Figure 4As shown, the servo valve automatic centering device (hereinafter referred to as the centering device) includes a mounting seat 3, a servo unit 4, a connecting rod unit 5, a detection unit 6 and a control unit 7, and the servo valve body 1 is set on the mounting seat 3 , the servo unit 4 is connected with the receiver 2 of the servo valve through the connecting rod unit 5, so that the receiver 2 can move relative to the servo valve body 1 with the connecting rod unit 5, the servo unit 4, the detection unit 6 ...

Embodiment 2

[0077] This embodiment provides an automatic centering method for a servo valve, using the above-mentioned servo valve automatic device for automatic centering, including the following steps:

[0078] Step 1: Install the servo valve body 1 on the mounting seat 3, loosen the positioning bolts connecting the receiver 2 and the servo valve body 1, and the receiver 2 can move relative to the servo valve body 1 under the action of external force;

[0079] Specifically, the servo valve body 1 is installed between the upper plate 322 and the lower plate 323, and is connected with the outlet of the air flow channel of the column 321, so that the servo valve body 1 can be connected with the external air source; the positioning bolt makes the receiver 2 and the servo valve The body 1 is connected and can move relative to the servo valve body 1;

[0080] Step 2: Connect the connecting rod unit 5 with the receiver 2, and connect the detection unit 6 with the air outlet A and the air outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com