Device and method for quickly detecting performance of OLED micro display

A micro-display and detection device technology, which is applied in the direction of measuring devices, optical instrument testing, and optical performance testing, to achieve the effects of reducing labor intensity, stable system operation, and improving measurement efficiency and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

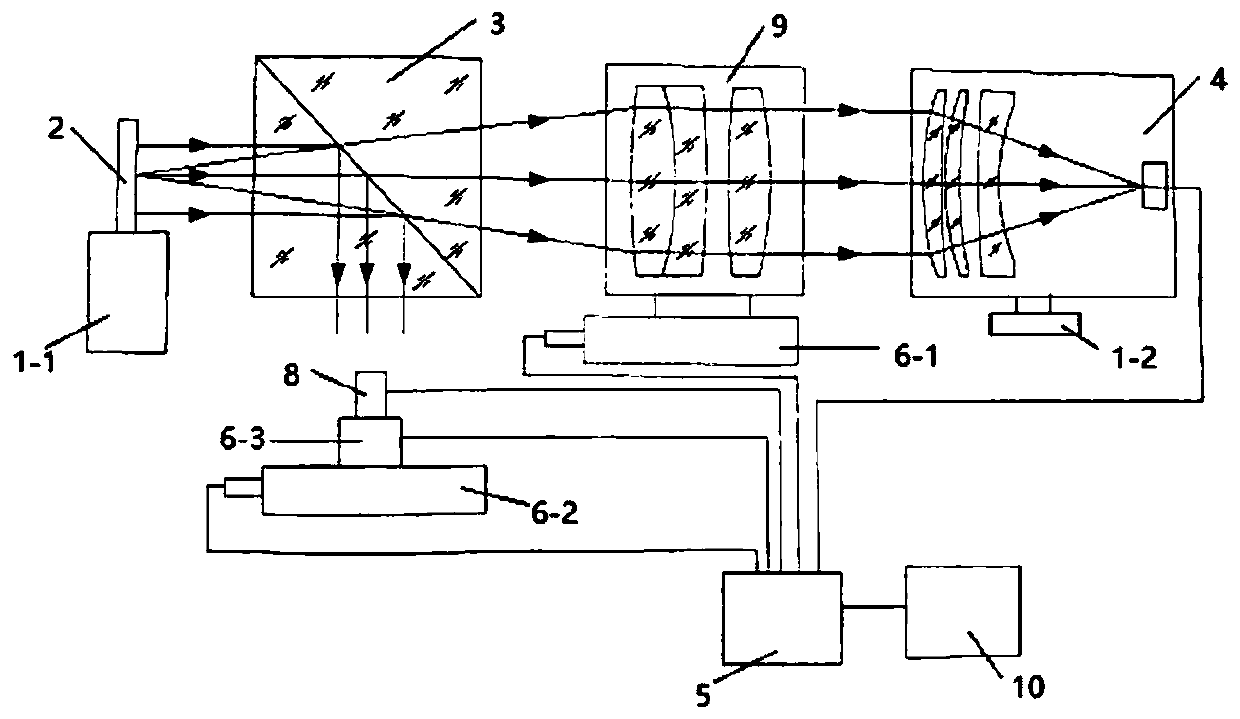

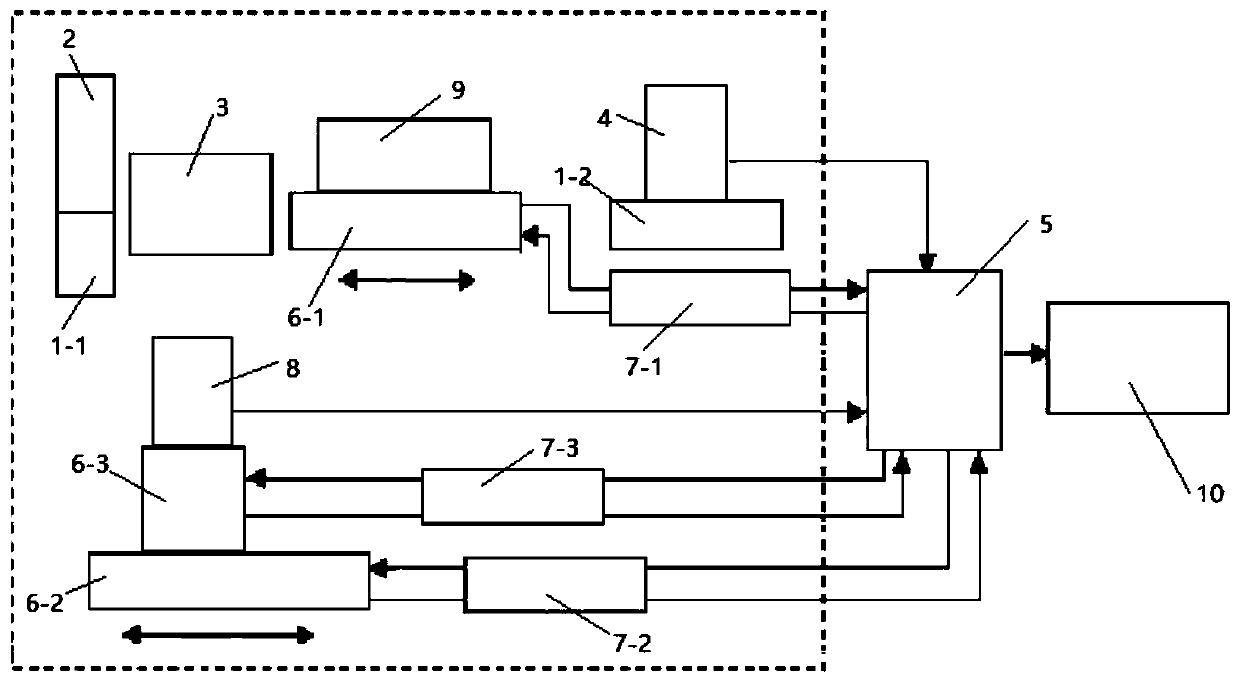

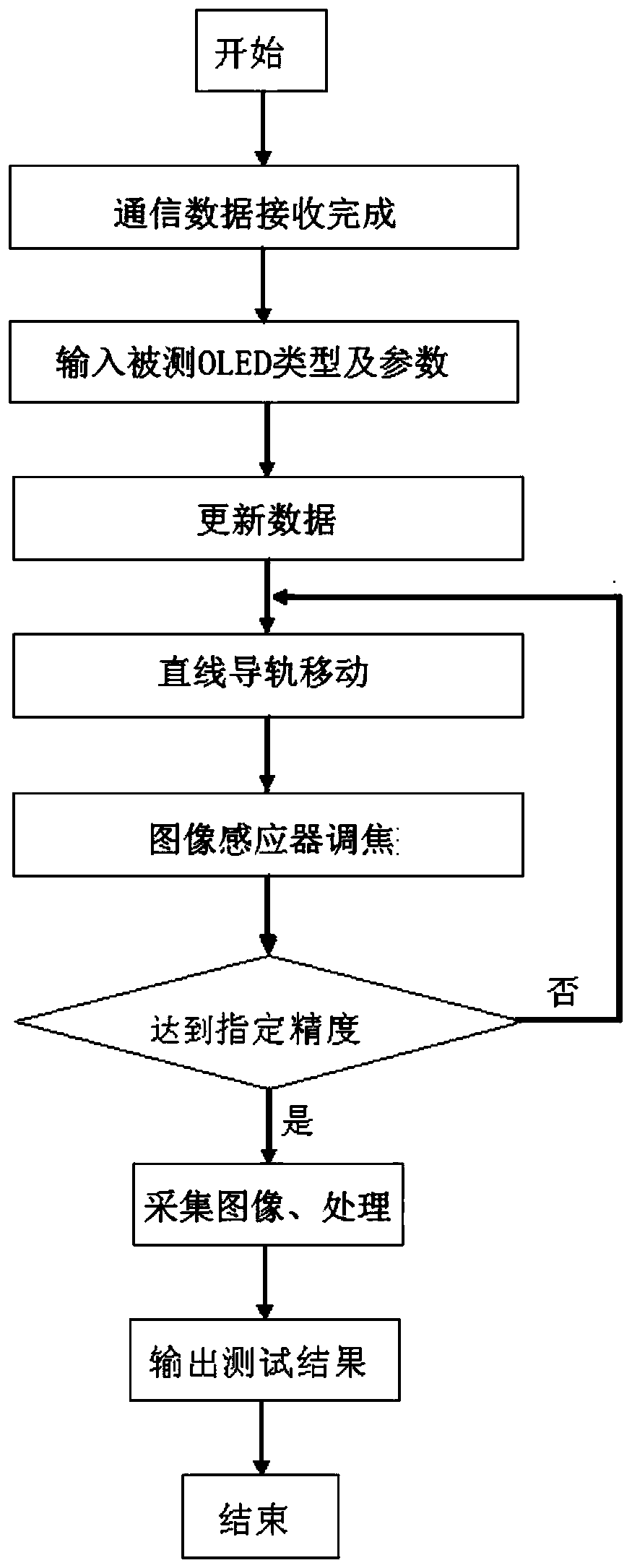

[0019] Example 1, such as Figures 1 to 4 As shown, the hardware composition of the present invention includes: a tooling bracket, a high-precision linear guide rail, a large field of view microscope objective lens, an image sensor, a luminance meter, a computer, a display, and the like. The OLED micro-display 2 is fixed on the tooling bracket I1-1, the semi-transparent and semi-reflective dichroic prism 3 is placed behind the OLED micro-display, and the image sensor 4 connected to the computer 5, the high-precision linear guide rail I6-1, and the high-precision linear guide rail II6 -2. High-precision linear guide rail Ⅲ6-3 and display 10, wherein the image sensor 4 is fixed on the tooling bracket Ⅱ1-2, and the high-precision linear guide rail Ⅰ6-1 is fixed on the large-field microscope objective lens assembly 9, and the high-precision linear guide rail Ⅲ6-3 is fixed on the high-precision linear guide rail Ⅱ6-2. The high-precision linear guide rail Ⅱ and the high-precision li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com