Method and system for identifying falling fault of rail wagon hook lifting rod

A technology for fault identification and railway wagons, applied in neural learning methods, character and pattern recognition, instruments, etc., can solve the problems of low accuracy rate, achieve the effect of improving accuracy rate, enhancing generalization ability, and reducing mis-segmented regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

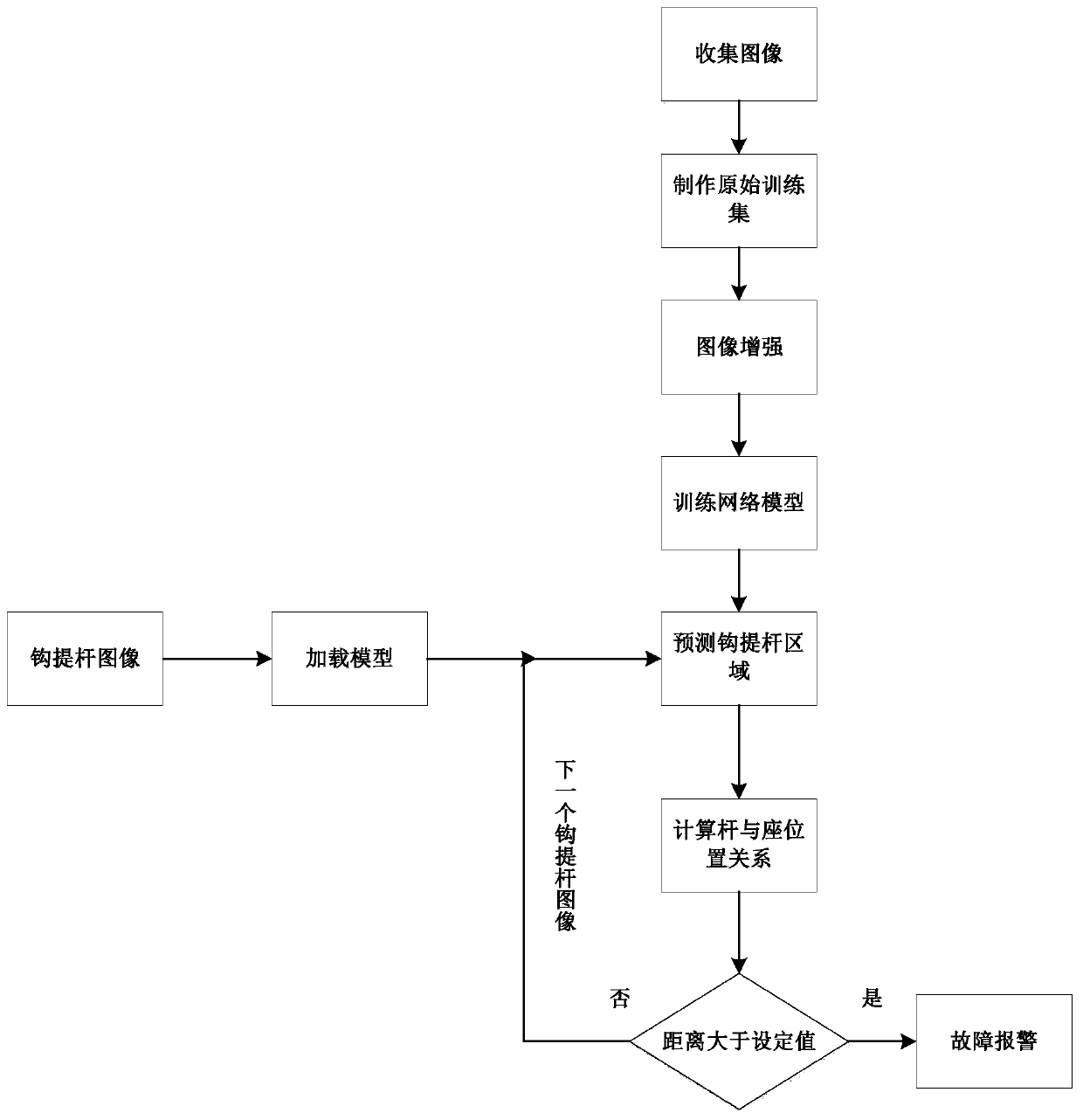

[0046] Specific implementation mode one: refer to figure 1 To describe this embodiment in detail,

[0047] The method and system for identifying the failure of the railway freight car hook lifting rod falling off described in this embodiment includes the following steps:

[0048] 1. Establish the training set required for the deep learning model

[0049] The high-definition grayscale image acquisition of the hook lifting rod is completed through the image acquisition equipment on both sides of the truck running rail. Since the truck is running in the open air, the hook lifting rod will be affected by natural conditions (such as: rain stains, mud stains, rust) and Man-made conditions (such as: oil stains) affect different grayscale changes in the image. Therefore, when collecting the data samples of the hook lifting rod in the early stage, it is necessary to ensure the diversity of the data as much as possible, and ensure that the samples cover the images of the hook lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com