Wagon coupler joist breaking detection method

A railway wagon and detection method technology, which is applied in the field of railway wagon safety, can solve problems such as low reliability, and achieve the effects of ensuring reliability, high accuracy of results, and improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

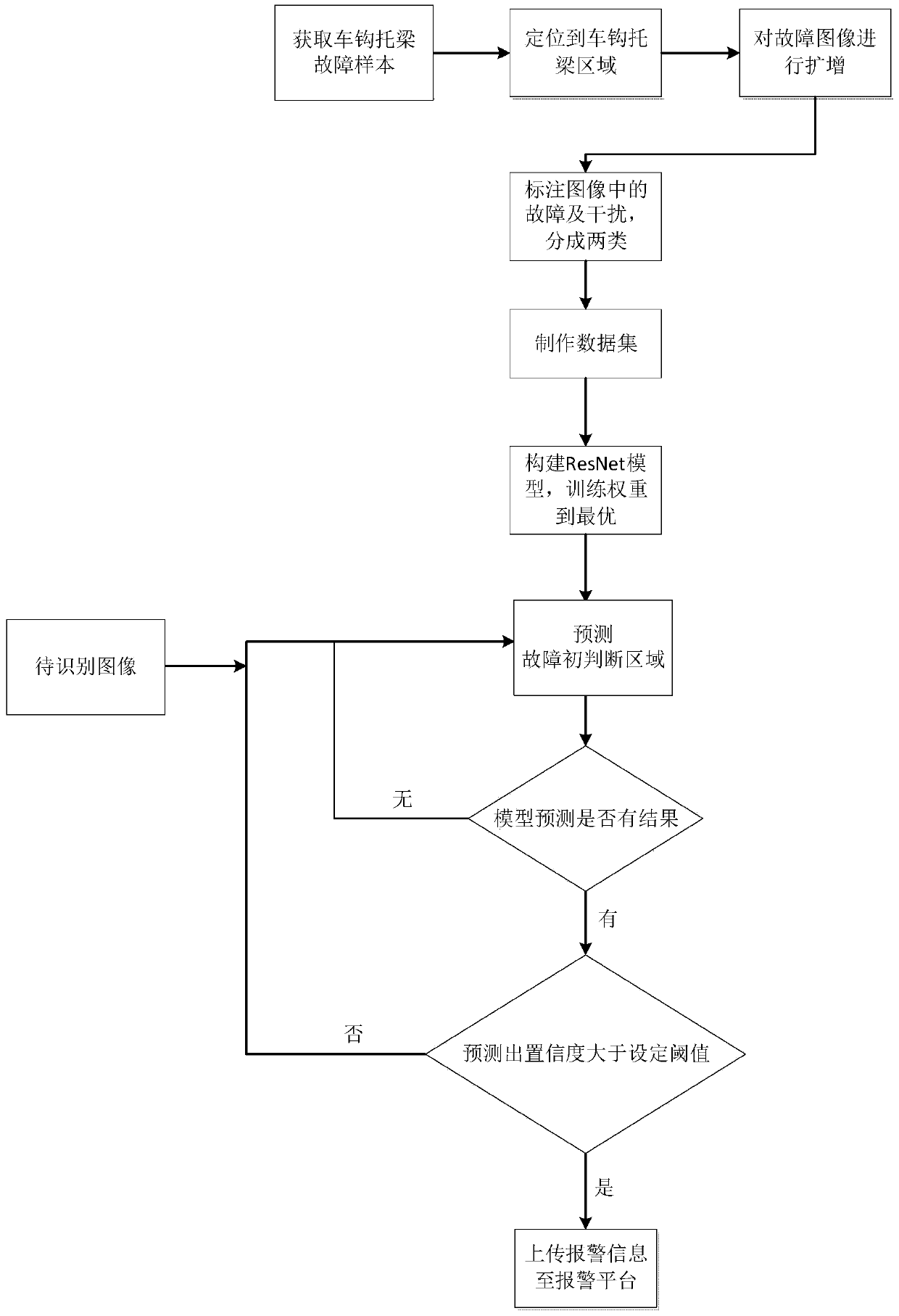

[0024] Specific implementation mode 1. Combination Figure 1 to Figure 3 As shown, the present invention provides a method for detecting the breakage of a railway wagon coupler joist, comprising the following steps:

[0025] Step 1: Establish a data set for training, mark the fault area or suspected fault area of the coupler joist fault sample in the data set, and mark the recognition frame by block, and configure a category label for each recognition frame, and the category label includes the fault class label and interference labels;

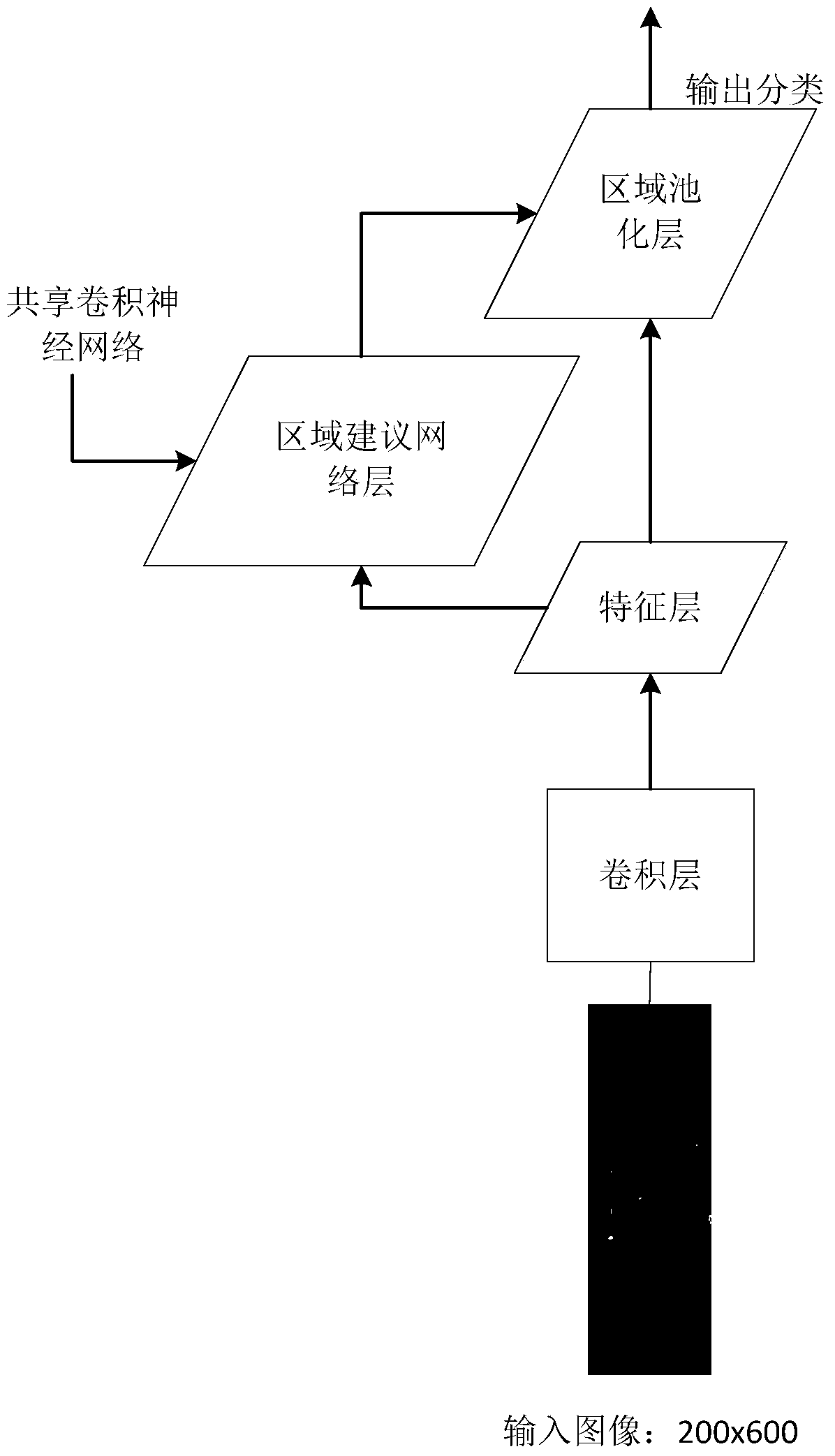

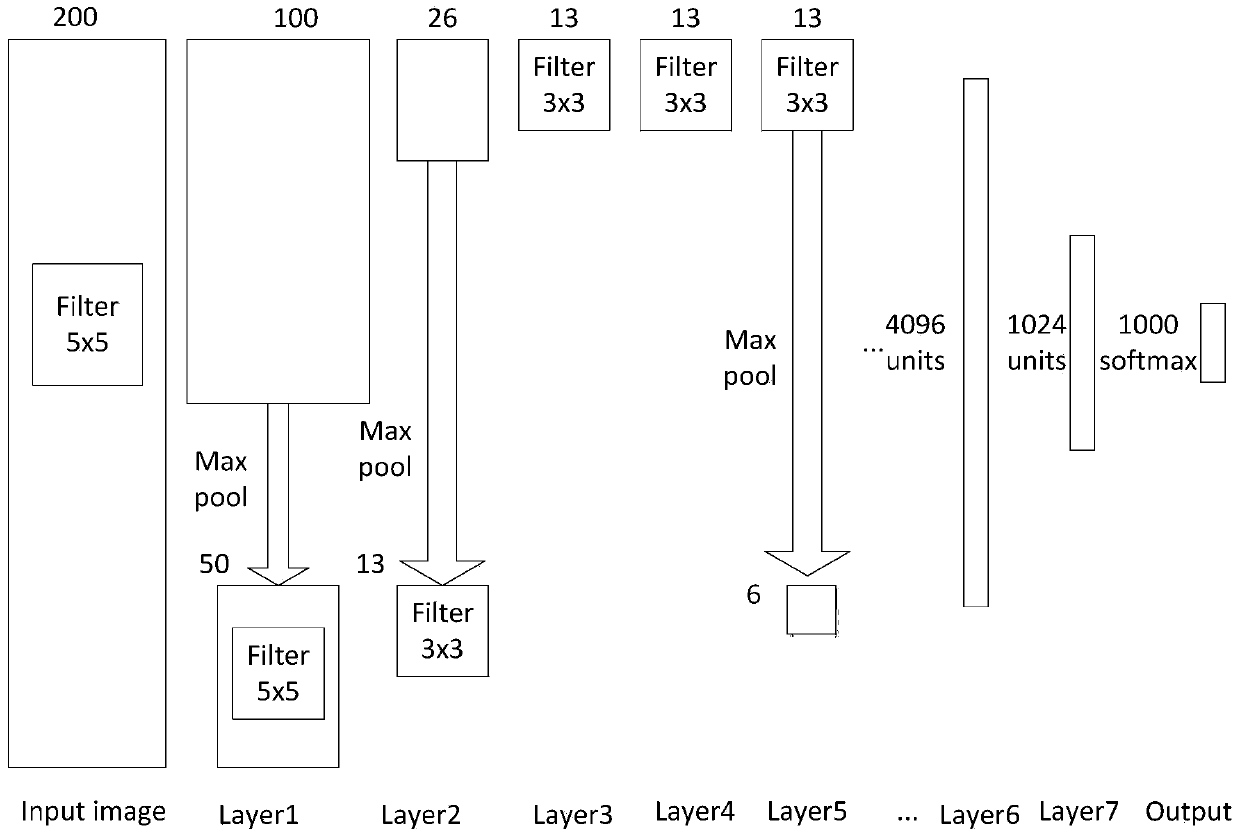

[0026] Step 2: Build a Faster-Rcnn model based on the ResNet detection model. The Faster-Rcnn model uses a convolutional layer, an activation function, and a pooling layer to extract the feature map of the input coupler joist fault sample; The convolution calculation generates a detection suggestion box; the area pooling layer extracts the suggestion feature from the detection suggestion box; the suggestion feature is sent to the fully conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com