Catalyst for improving para-selectivity of phenol hydroxylation reaction product, preparation method and application thereof

A technology of phenol hydroxylation and reaction product is applied in the field of catalyst preparation for improving the para-selectivity of phenol hydroxylation reaction product, and can solve serious environmental pollution, small production scale, and low yields of catechol and hydroquinone. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

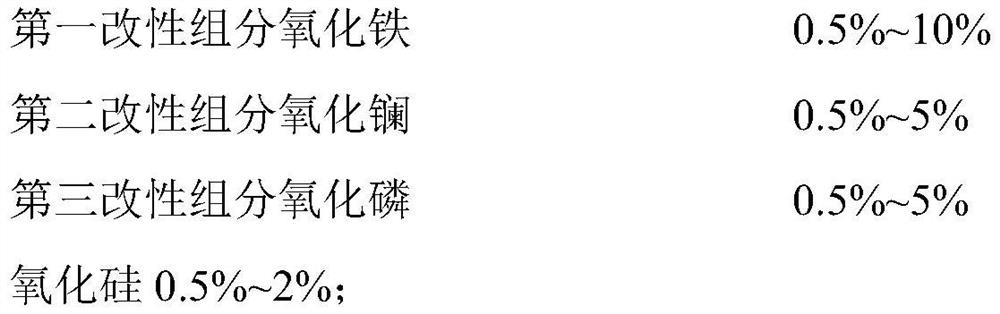

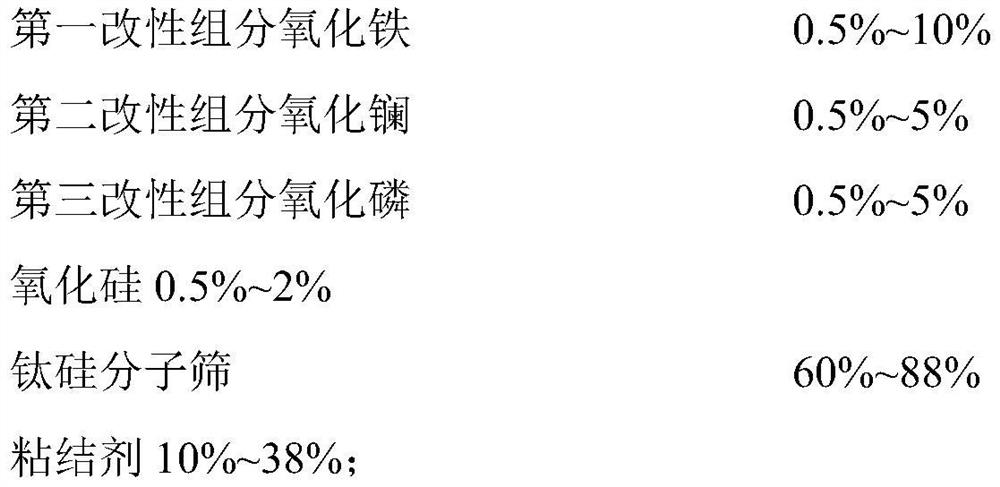

Method used

Image

Examples

preparation example Construction

[0038] Preparation of Extruded Ti-Si Molecular Sieve Catalyst

[0039] The above molecular sieve mother liquor was centrifuged, dried and calcined at 540° C. for 4 hours to obtain a titanium silicon molecular sieve. Weigh 500g of titanium-silicon molecular sieve, 446g of silica sol (28wt%) and 20g of scallop powder, mix them uniformly, add appropriate amount of deionized water, fully knead and shape in extruder. Place at room temperature for 12h. Then it was dried at 100°C for 12h, and then calcined at 540°C for 3h.

[0040] Preparation of Microspherical Ti-Si Molecular Sieve Catalyst

[0041]Weigh 1000g of titanium-silicon molecular sieve mother liquor, the molecular sieve solid content is 12%, add 250g of silica sol (28wt%), stir for 24h, and adopt spray drying to form. The spray drying molding conditions are: inlet temperature: 200°C, outlet temperature: 110°C. After molding, it is dried at 35-120°C and calcined at 500-600°C to obtain microspherical titanium-silicon mol...

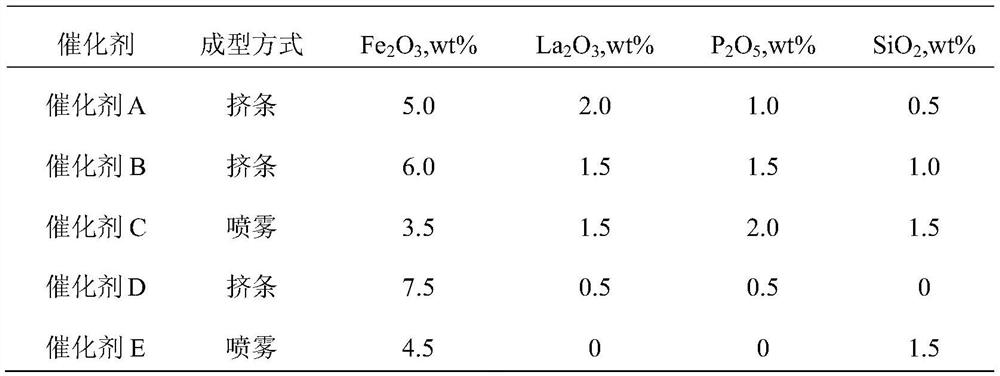

Embodiment 1

[0043] Mix 5.1 g of ferric nitrate with 15 ml of deionized water to obtain an iron-containing impregnation solution. 20 g of the extruded titanium-silicon molecular sieve catalyst was impregnated with the above impregnating solution at room temperature for 12 hours. Dry at 100°C for 12h, and bake at 540°C for 4h. Then 1.1 g of lanthanum nitrate, 0.4 g of diammonium hydrogen phosphate and 15 ml of deionized water were mixed. The above catalyst was placed in the impregnation solution for 12h. Dry at 100°C for 12h, and bake at 540°C for 4h. The catalyst was then immersed in 15 mL of a cyclohexane solution containing 0.3 g of tetraethylorthosilicate. Immerse at room temperature for 6h, dry at 100°C for 12h, and bake at 540°C for 4h. Catalyst A is obtained.

Embodiment 2

[0045] Mix 6.0 g of ferric chloride with 15 ml of deionized water to obtain an iron-containing impregnation solution. 20 g of the extruded titanium-silicon molecular sieve catalyst was impregnated with the above impregnating solution at room temperature for 12 hours. Dry at 100°C for 14h, and bake at 550°C for 4h. Then 1.5 g of lanthanum nitrate, 1.5 g of diammonium hydrogen phosphate and 15 ml of deionized water were mixed. The above catalyst was placed in the impregnation solution for 12h. Dry at 100°C for 16h, and bake at 550°C for 6h. The catalyst was then immersed in 15 mL of a cyclohexane solution containing 0.7 g of tetraethylorthosilicate. Immerse at room temperature for 6h, dry at 100°C for 12h, and bake at 540°C for 4h. Catalyst B is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com