Rolling forming method of T-type cross section full fiber gear ring

A full-fiber, cross-section technology, applied in metal rolling, metal processing equipment and other directions, can solve the problems of poor forging streamline, low material utilization rate, large processing allowance in the production of T-section ring gear, etc., to reduce processing The effect of surplus, good flow, and improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, taking a ring gear forging with a material of 42CrMoA and a specification of Φ1495mm×Φ1220mm×Φ1080mm×360mm×70mm (Df0×df0×df1×H×Hf) as an example.

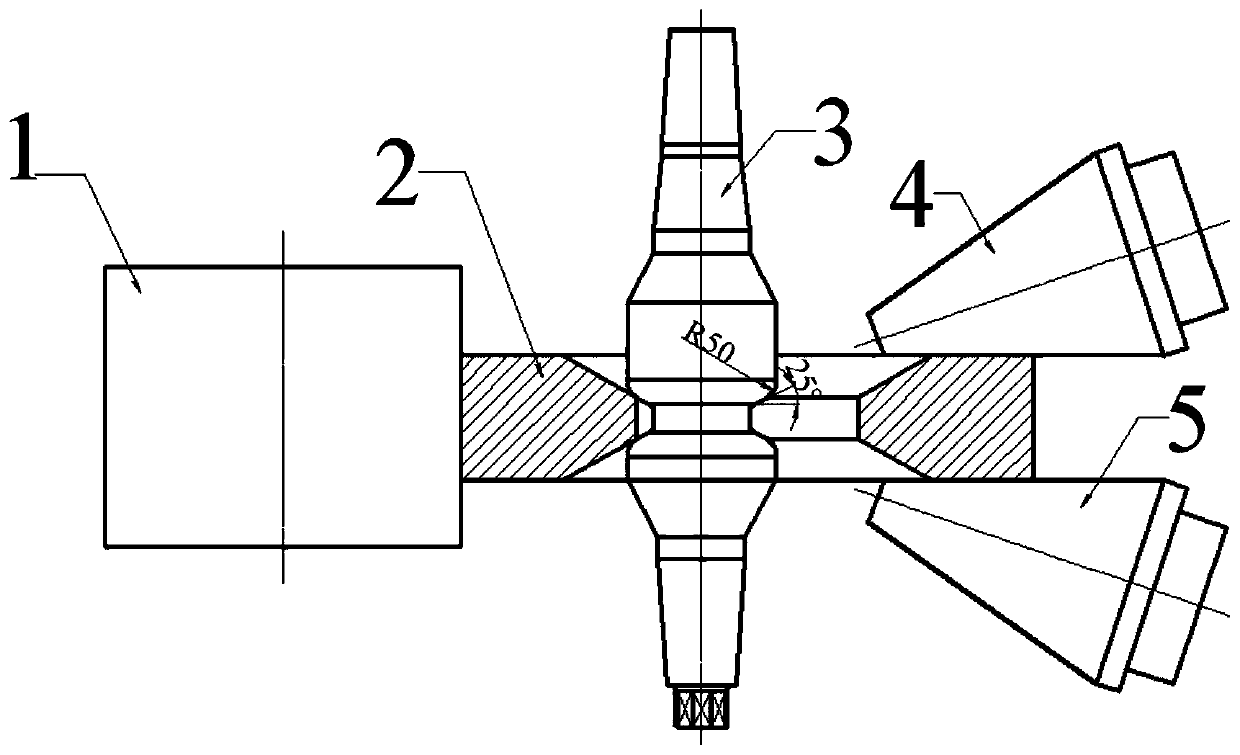

[0028] Such as image 3 As shown, a rolling forming method of a T-shaped cross-section full-fiber ring gear specifically includes the following steps:

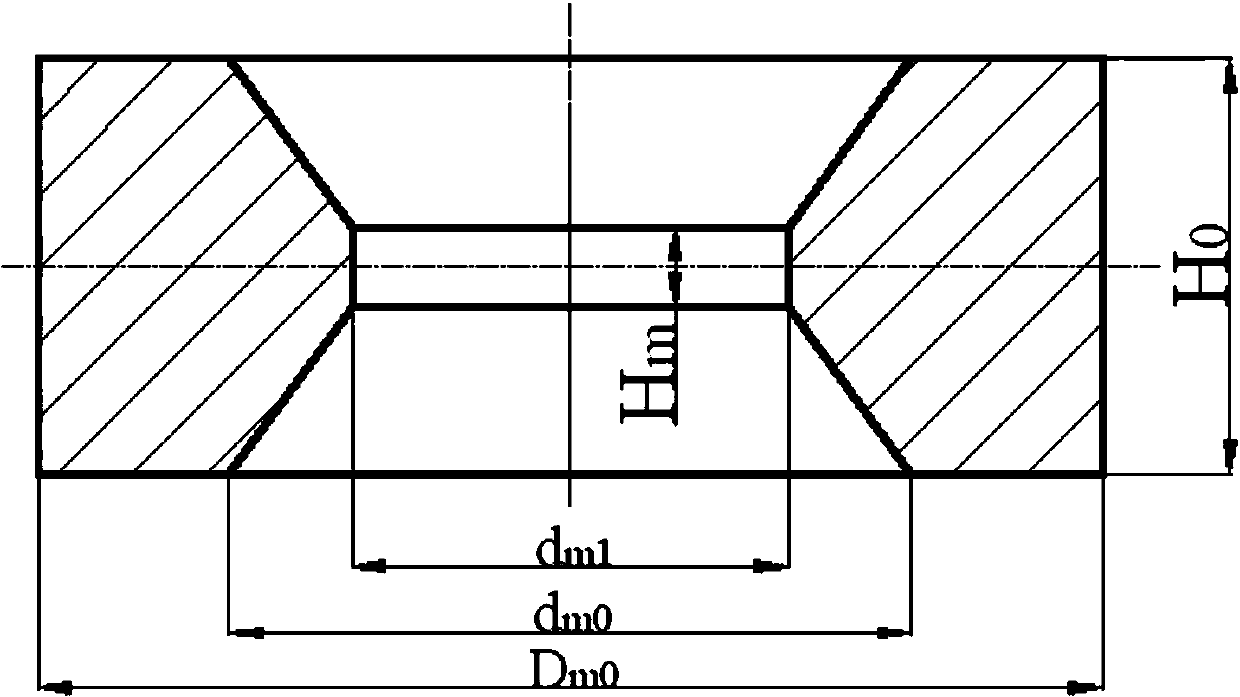

[0029] Step 1. Ring blank design: design the ring blank 2 according to the forging size, core roll size, deformation distribution ratio, deformation law and cross-section similarity principle, among which D m0 1035mm, d mo 600mm, d m1 370mm, H 0 360mm, H m 70mm.

[0030] Step 2. Blanking and heating: Blanking is carried out according to the weight of the forging, heated to 850°C and kept for 1-2 hours, then continue to heat up to the initial forging temperature of 1150°C, and kept for 2-3 hours;

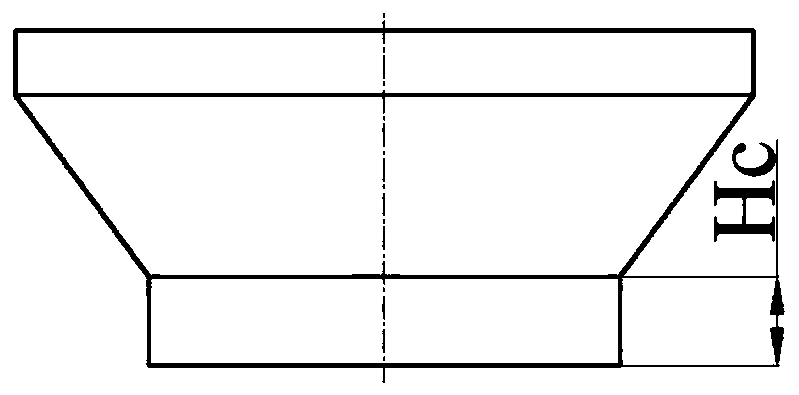

[0031] Step 3. Billet making: Upsetting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com