A kind of graphene composite sand-in-sand colorful coating and preparation method thereof

A graphene composite and colorful coating technology, applied in the field of coatings, can solve the problems of shortened service life, limited scope of application, poor stain resistance, etc., and achieve the effects of improved stain resistance, excellent flexibility, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

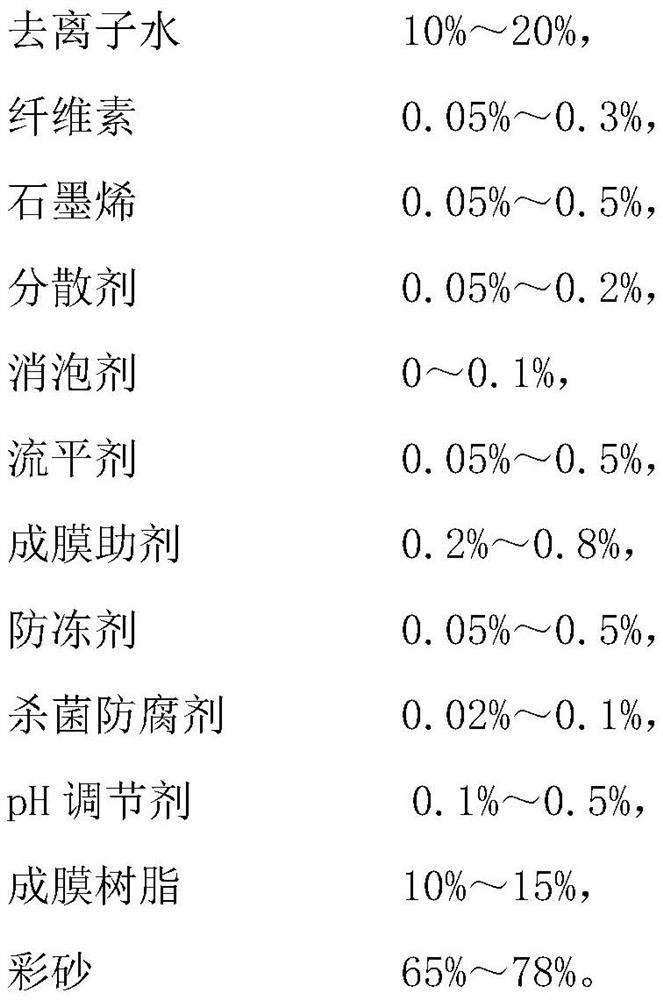

[0035] A graphene composite sand-in-sand multi-color paint, mainly composed of protective colloid solution, base paint solution and continuous phase solution, the mass ratio of protective colloid solution, basic paint solution and continuous phase solution is 1:2:3, wherein the protective colloid The solution is composed of the following raw materials and their mass percentages: deionized water 95%, protective rubber powder 4.8%, bactericidal preservative 0.2%; the base paint solution is composed of the following raw materials and their mass percentages: deionized water 31.05%, cellulose 0.7% , 0.2% graphene, 0.5% defoamer, 0.4% dispersant, 0.7% film-forming aid, 0.7% antifreeze, 0.15% pH regulator, 5% protective gel solution, 0.3% thickener, bactericidal preservative 0.3%, film-forming resin 15%, curing agent 2%, colored sand 43%; the continuous phase solution consists of the following raw materials and their mass percentages: deionized water 10%, cellulose 0.15%, graphene 0.2...

Embodiment 2

[0042] A kind of graphene composite sand-in-sand colorful coating, mainly is made up of protective colloid solution, basic paint solution and continuous phase solution, and the mass ratio of protective colloid solution, basic paint solution and continuous phase solution is 1:1:3, wherein protective colloid The solution is composed of the following raw materials and their mass percentages: 96% deionized water, 4% protective rubber powder; the base paint solution is composed of the following raw materials and their mass percentages: 40% deionized water, 0.3% cellulose, 0.05% graphene, 0.1% defoamer, 0.05% dispersant, 0.4% film-forming aid, 0.2% antifreeze, 0.05% pH regulator, 2% protective glue solution, 0.1% bactericidal preservative, 10% film-forming resin, colored sand 46.75 %; The continuous phase solution is composed of the following raw materials and their mass percentages: 11.43% deionized water, 0.05% cellulose, 0.05% graphene, 0.05% dispersant, 0.05% leveling agent, 0.2%...

Embodiment 3

[0049] A kind of graphene composite sand-in-sand colorful coating, mainly is made up of protective colloid solution, basic paint solution and continuous phase solution, and the mass ratio of protective colloid solution, basic paint solution and continuous phase solution is 1:2:5, wherein protective colloid The solution is composed of the following raw materials and their mass percentages: deionized water 90%, protective rubber powder 9.2%, bactericidal preservative 0.8%; the base paint solution is composed of the following raw materials and their mass percentages: deionized water 25%, cellulose 1% , 0.5% graphene, 0.8% defoamer, 0.8% dispersant, 1% film-forming aid, 1.2% antifreeze, 0.3% pH regulator, 8% protective gel solution, 0.8% thickener, bactericidal preservative 0.5%, film-forming resin 20%, curing agent 4%, colored sand 36.1%; the continuous phase solution consists of the following raw materials and their mass percentages: deionized water 20%, cellulose 0.3%, graphene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com