A municipal rainwater pipeline assembly module and construction method

A rainwater and pipeline technology, applied in the field of municipal rainwater pipeline assembly modules and construction, can solve problems such as dislocation of drainage pipelines, reduced service life, irregular load of pipelines, etc., to achieve uniform pressure conduction, increase service life, and improve the protection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

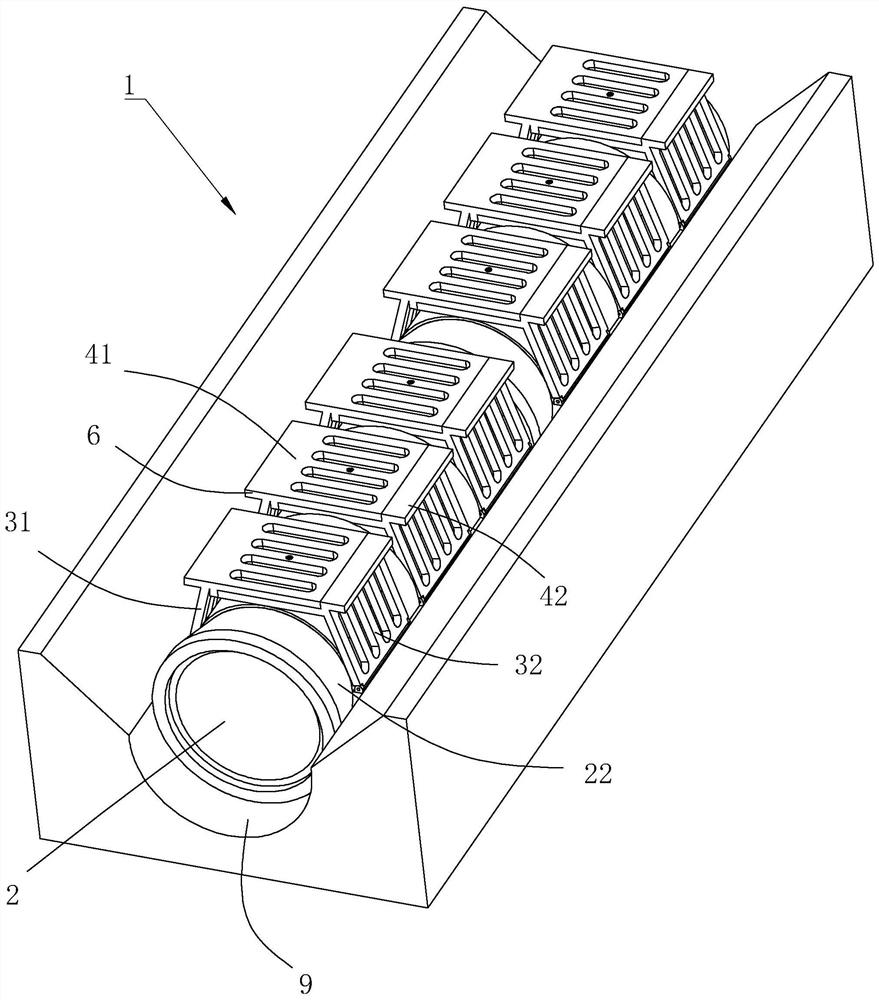

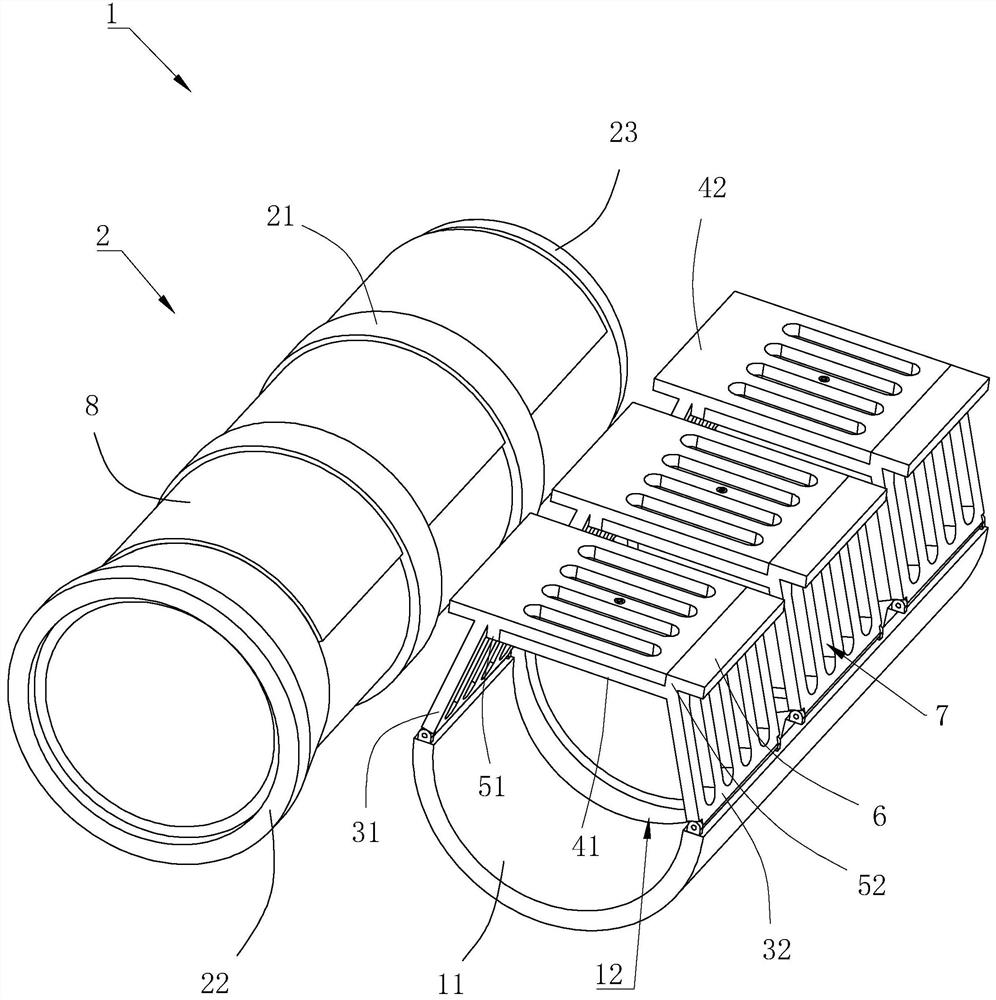

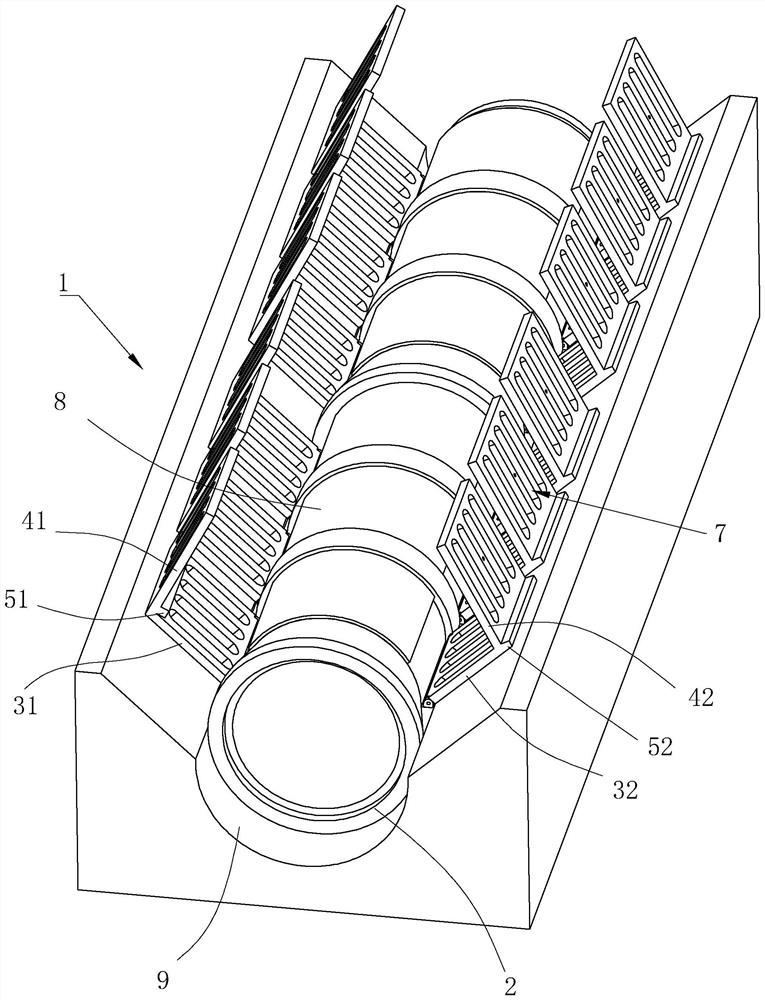

[0040] Such as Figure 1 to Figure 2 As shown, a municipal rainwater pipeline assembly module disclosed by the present invention includes a number of interconnected module monomers 1. The module monomer 1 includes an arc-shaped support base 11 for placing at the bottom of the groove 9. The support base The arc opening of 11 is set upwards, and the cylindrical socket pipe 2 is clamped in the support base 11, and the support base 11 fits the socket pipe 2 and the central angle of the support base 11 is not greater than 180 degrees. The socket 22 and the socket 23 are fixed at both ends of the socket pipe 2, and the socket 22 and the socket 23 are set out from the support base 11. Sockets 23 are inserted into each other to realize connection.

[0041] Wherein the outer peripheral surface of the socket pipe 2 is fixed with several spacer rings 21 at intervals, and the opening of the supporting base 11 is provided with a spacer groove 12 corresponding to the position of the spacer...

Embodiment 2

[0047] A municipal rainwater pipeline assembly module construction method, comprising the following steps:

[0048] a. Prefabricated and assembled modules in the factory;

[0049] b. On-site measurement and setting out, excavation of trenches 9;

[0050] c. Install the assembly module in the groove 9;

[0051] d. Trench 9 backfill.

[0052] The implementation principle of this embodiment is:

[0053] The assembly modules are prefabricated by the factory to reduce costs, and the support base 11 and the socket pipe 2 are prefabricated and hoisted into the groove 9 together, and the adjacent assembly modules are connected to each other through the socket pipe 2. Then backfill the excavated earthwork assembly into the trench 9, bury the assembly module, and fill up the first support plate 31, the second support plate 32, the first support plate 31, the first support plate 32, and the first support plate with the finely divided earth through the through hole 7. The gap between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com