Fireproof door leaf structure

A technology of door leaves and packing columns, which is applied in the field of furniture, can solve problems such as affecting the opening or closing of fire doors, affecting the fire resistance of fire doors, and existing safety hazards, so as to reduce the possibility of deformation, avoid extrusion, and avoid deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

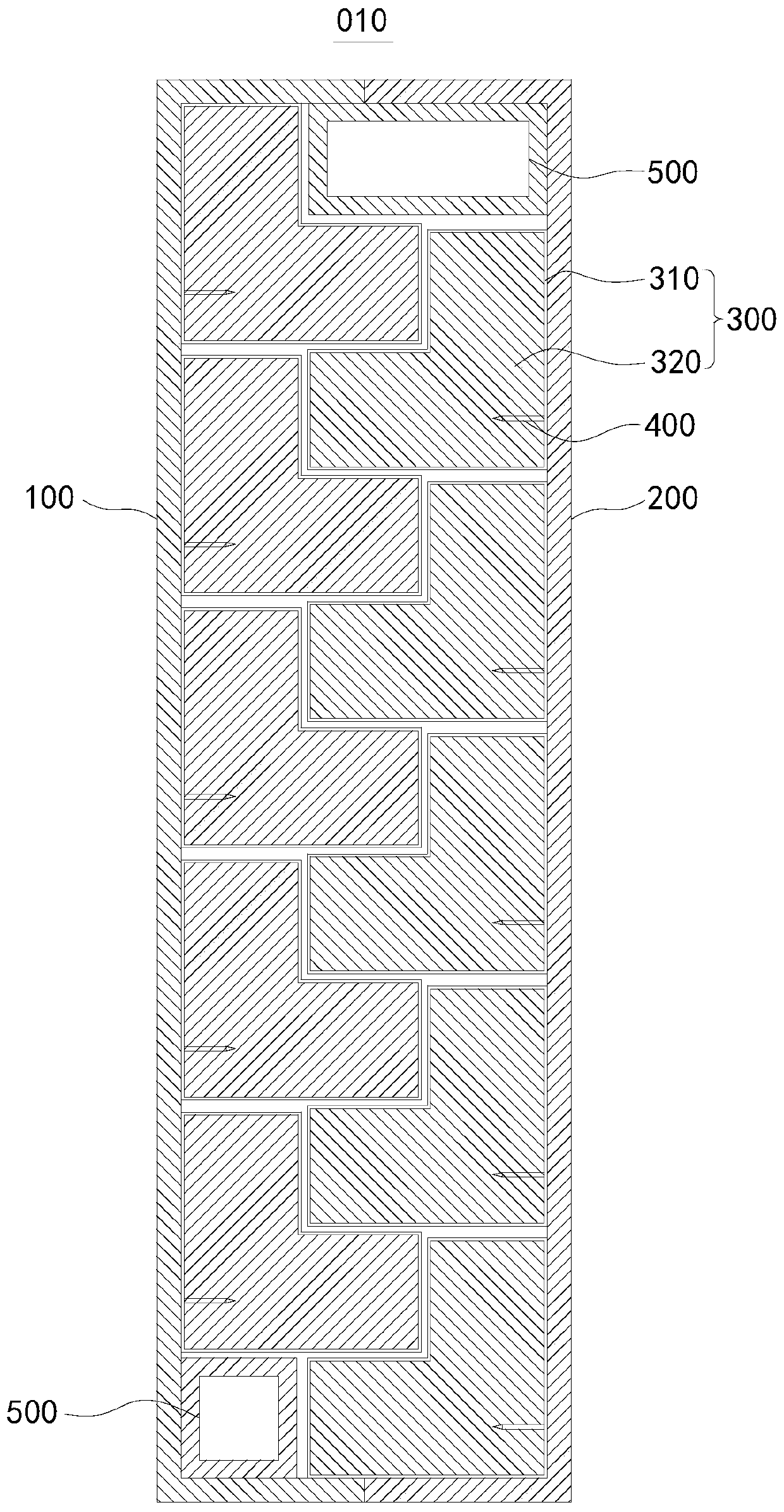

[0029] figure 1 A schematic diagram of the fire door structure 010 provided in this embodiment. Please refer to figure 1 , The fireproof door leaf structure 010 provided in this embodiment includes a door leaf panel 100 , a door leaf back plate 200 and a packing column 300 .

[0030] The door panel 100 and the door back panel 200 can be matched by means of welding or buckle connection. In this embodiment, the door panel 100 and the door back panel 200 are fitted together by welding. The door panel 100 and the door back panel 200 jointly form a stuffing chamber.

[0031] Packed column 300 includes bundled mesh 310 and packing 320 . The beam net 310 is made of iron wire, and the filler 320 can use fireproof materials such as asbestos. The filler 320 is filled into the bundle-type mesh 310 , thereby forming the filler column 300 . A plurality of packing columns 300 are disposed within the packing cavity. The packing column 320 extends along the vertical direction of the pa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap