Packing device for pump shaft

A technology for pump shafts and packing glands, applied to parts, pumps, and pump components of pumping devices for elastic fluids, which can solve problems such as leakage, and achieve the effects of avoiding leakage, easy filling, and uniform compression deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

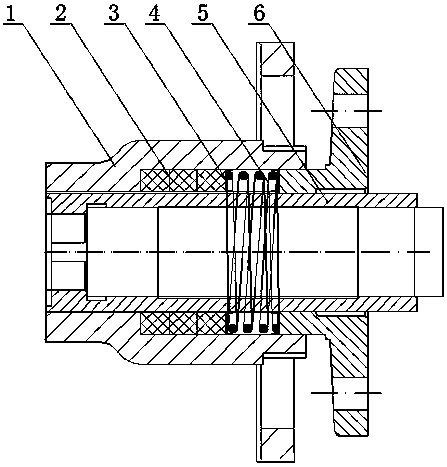

[0013] As shown in the figure, the automatic compensation shaft seal device for a pump includes a pump cover 1 , a packing 2 , a thrust plate 3 , a thrust spring 4 , a shaft sleeve 5 and a packing gland 6 . The shaft sleeve 5 is coaxially arranged in the pump cover 1 to form a cavity, and the cavity is tightly filled with packing 2, and the packing 2 is in close contact with the left convex surface of the pump cover 1 to seal, and the right end surface of the pump cover 1 is provided with a packing Gland 6, packing gland 6 is coaxially socketed on the shaft sleeve 5 through its central round hole, the head of the packing gland 6 extends into the inner cavity of the pump cover 1, the head of the packing gland 6 and the packing The two rooms are provided with a thrust spring 4, the left side of the thrust spring 4 is extruded by the thrust plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com