High-speed multi-station piston ring-cylinder liner sliding pair friction test machine

A friction testing machine, multi-station technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of slow test process, unsuitable for high-speed occasions, unable to test friction and wear conditions, etc., to speed up the test process, Ingenious design, avoiding the effect of wire being pulled off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

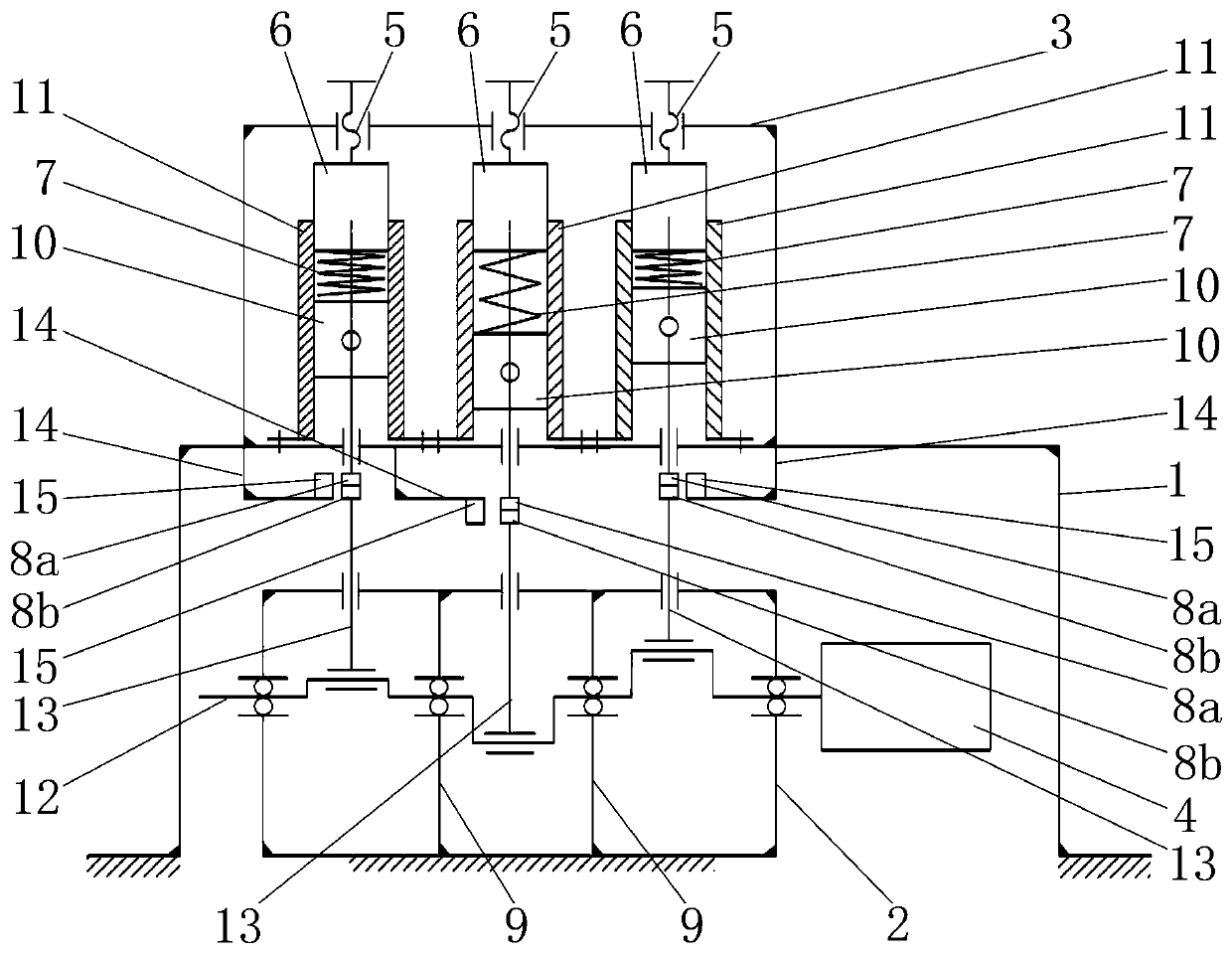

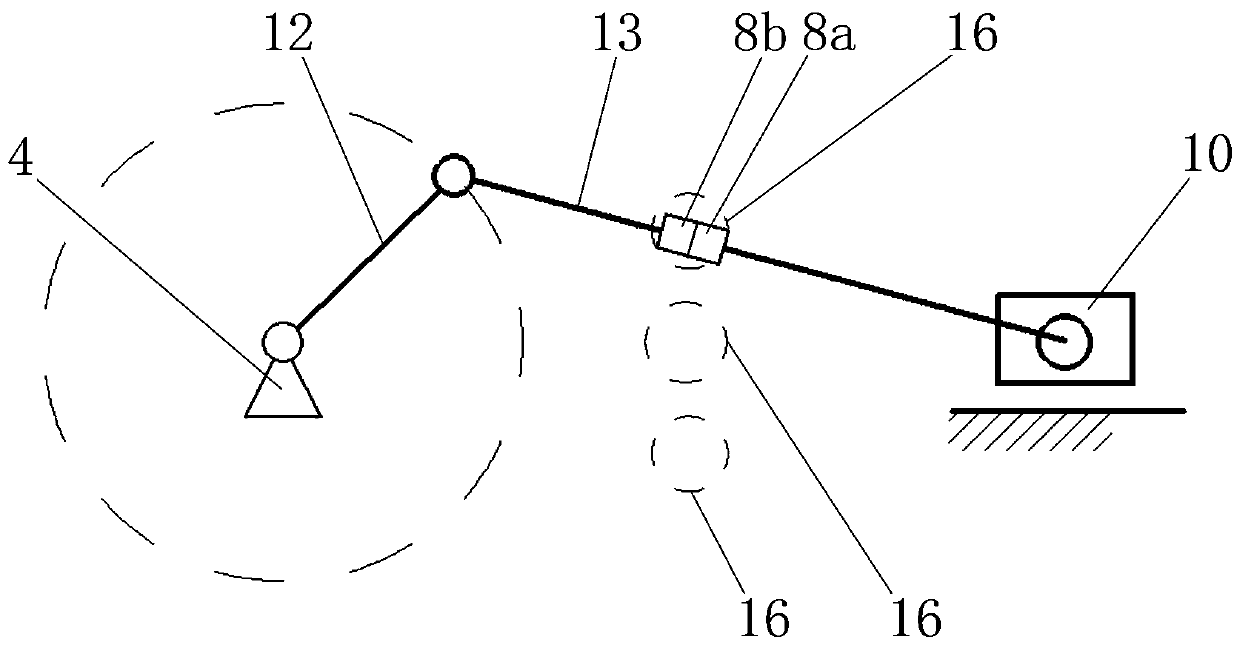

[0016] A high-speed multi-station piston ring-cylinder liner sliding pair friction testing machine, including a first box-shaped frame 1, a second box-shaped frame 2, a third box-shaped frame 3, a crank connecting rod mechanism, and a frequency conversion motor 4 , N loading screws 5, N pressure sensors 6, N compression springs 7, N wireless passive strain gauge sensors 8a, N wireless passive inclination sensors 8b; N is a positive integer, and N≥2;

[0017] Wherein, the first box-shaped frame 1 is fixed on the ground; the lower end, the front end and the rear end of the first box-shaped frame 1 are all provided with openings; the upper side wall of the first box-shaped frame 1 is provided with N The first through hole, and N first through holes are arranged equidistantly from left to right; the second box-shaped frame 2 is fixed on the ground, and the second box-shaped frame 2 is located inside the first box-shaped frame 1 cavity; the front end and rear end of the second box-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com