Monitoring of MEMS mirror properties

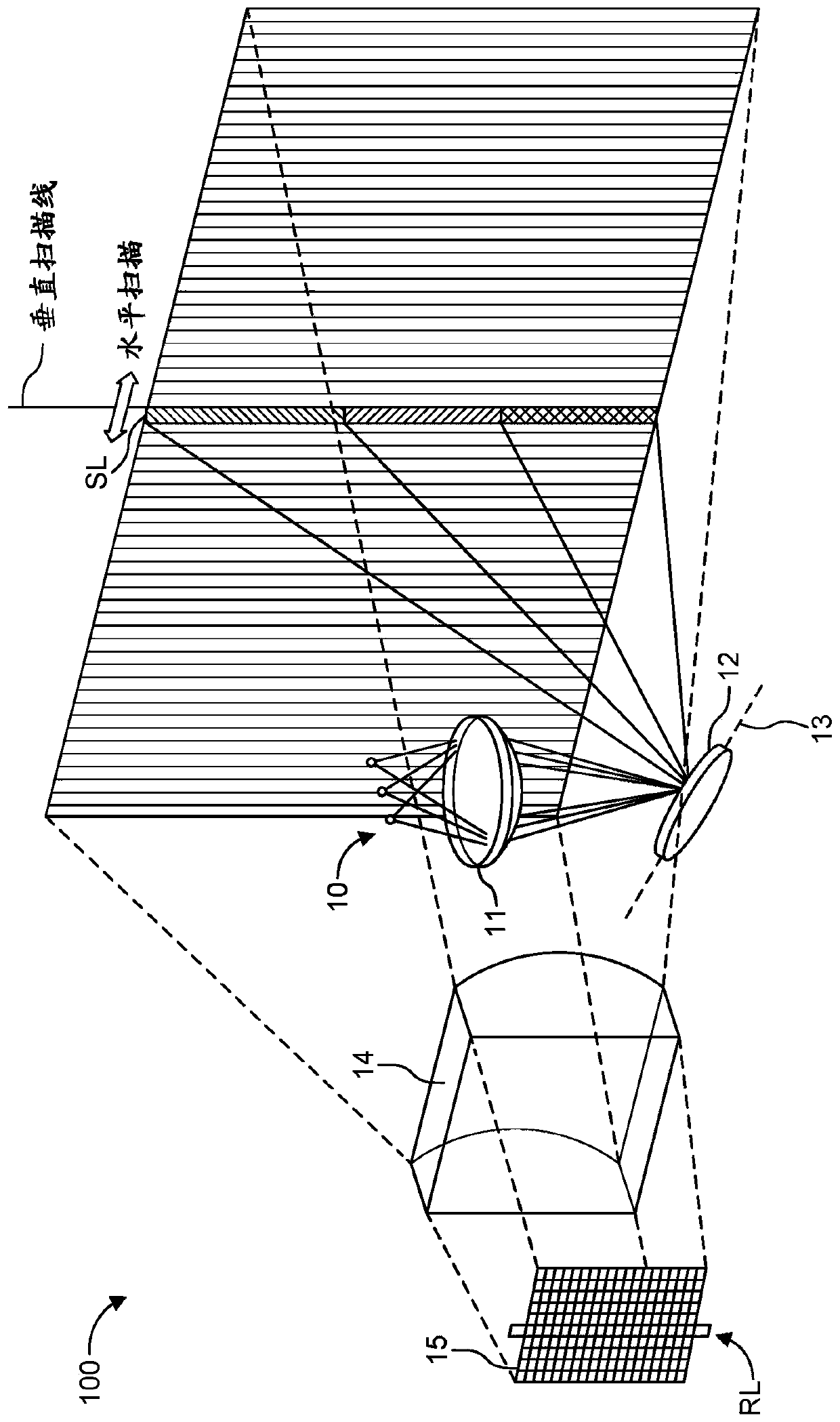

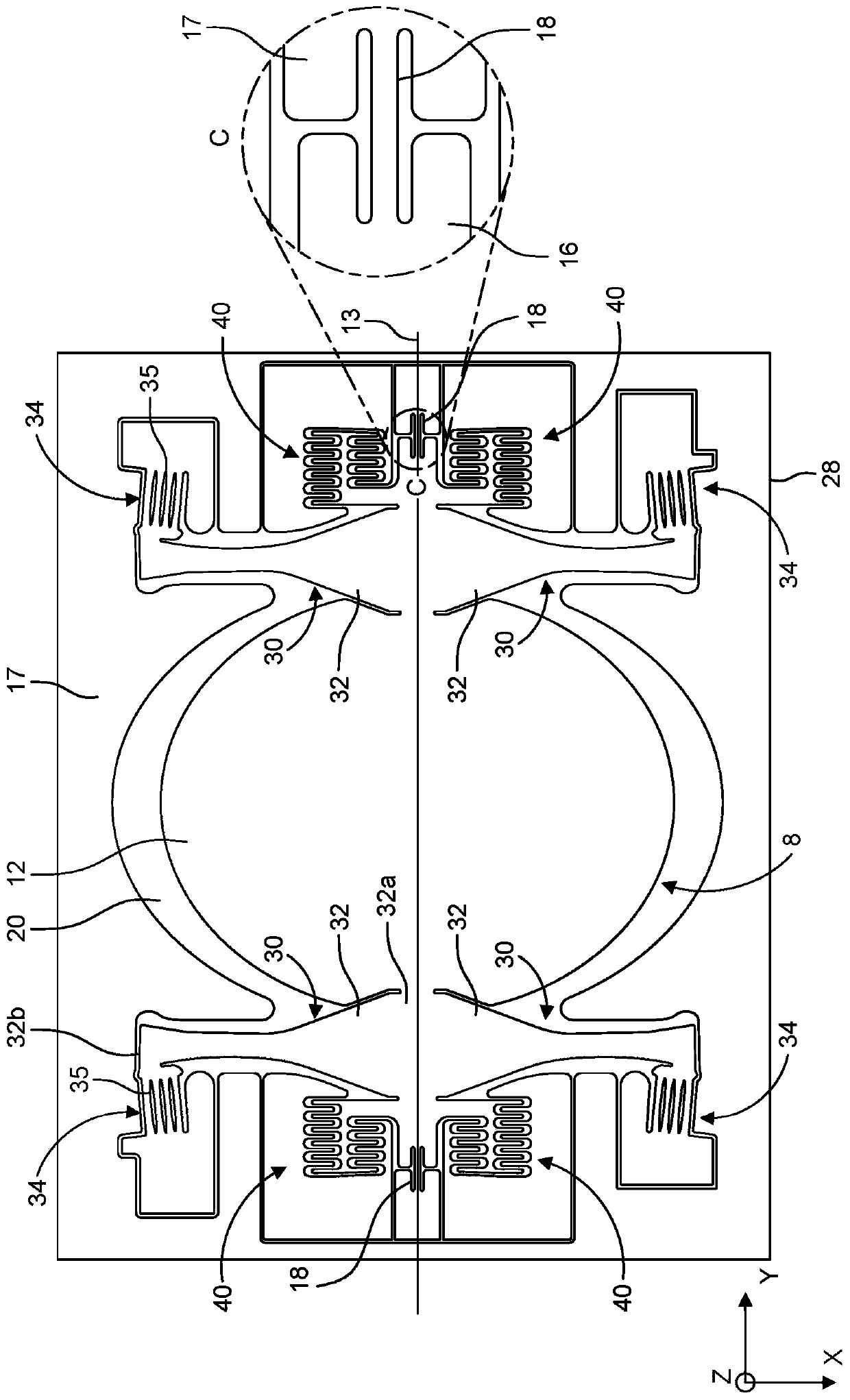

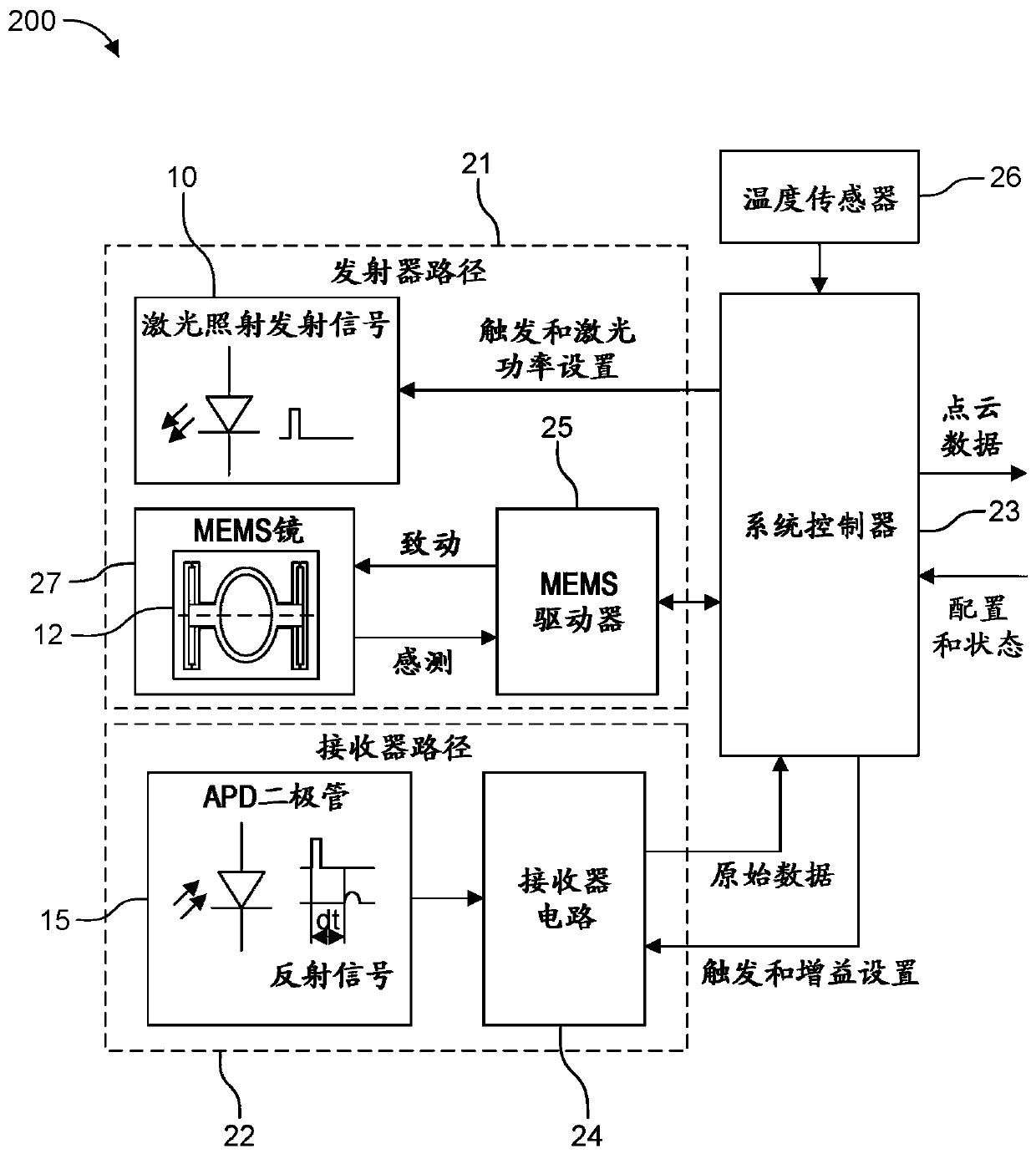

A characteristic, nonlinear resonance technology used in the field of MEMS oscillatory systems to solve problems such as mismatches, laser shooting/printing errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, various embodiments will be described in detail with reference to the accompanying drawings. It should be noted that these examples are for illustrative purposes only and should not be construed as limiting. For example, although an embodiment may be described as including several features or elements, this should not be interpreted as indicating that all such features or elements are required to practice the embodiment. Conversely, in other embodiments, some features or elements may be omitted, or may be substituted for alternative features or elements. Furthermore, other features or elements than those explicitly shown and described may be provided, for example conventional components of a sensor device.

[0019] Unless specifically stated otherwise, features from different embodiments may be combined to form other embodiments. Variations or modifications described with respect to one of the embodiments may also be applicable to the other embodiments. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com