Photosensitive coloring composition, cured film, method for forming pattern, color filter, solid-state imaging element and image display device

A coloring composition, a photosensitive technology, applied in photosensitive material processing, photoengraving process of pattern surface, photosensitive material used in optomechanical equipment, etc., can solve problems such as low heat resistance, and achieve excellent discoloration resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0365]

[0366] The photosensitive coloring composition of this invention can mix and prepare the said component. When preparing the photosensitive coloring composition, all the components can be dissolved and / or dispersed in the solvent at the same time to prepare the photosensitive coloring composition, and each component can also be properly prepared as two or more kinds of solutions or dispersions according to needs, And these are mixed at the time of use (at the time of coating), and the photosensitive coloring composition is prepared.

[0367] Moreover, when preparing the photosensitive coloring composition containing a pigment, the process of dispersing a pigment is also preferable at the time of preparing a photosensitive coloring composition. In the step of dispersing the pigment, compression, extrusion, impact, shearing, cavitation and the like are mentioned as the mechanical force used in the dispersion of the pigment. Specific examples of these steps include bea...

Embodiment 1

[0420] After mixing and stirring the raw materials shown below, it filtered with the nylon filter (manufactured by NIHONPALL LTD.) with a pore diameter of 0.45 micrometers, and the photosensitive coloring composition was prepared.

[0421] ·Pigment dispersion P1...60.0 parts by mass

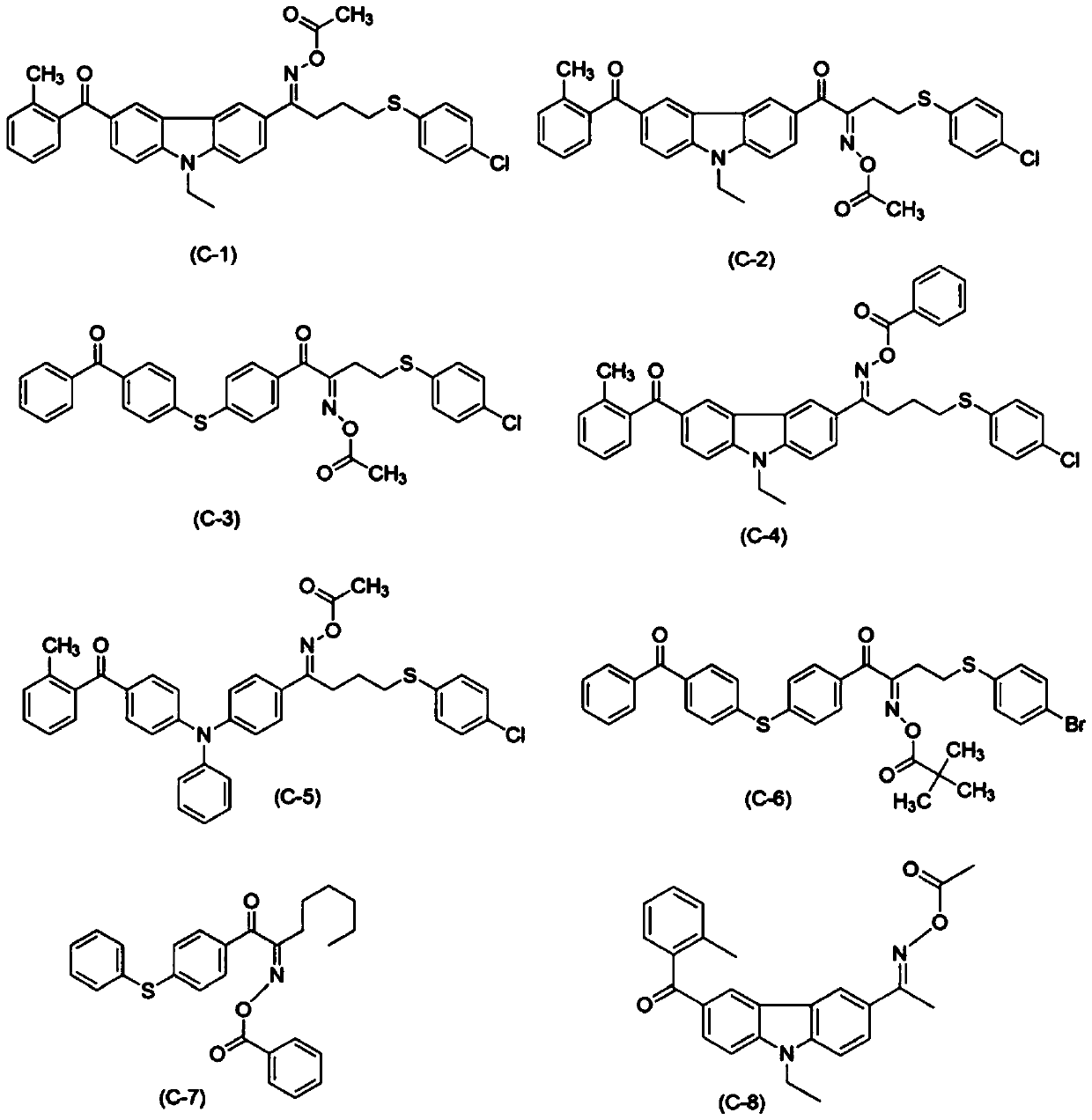

[0422] ・Photopolymerization initiator (initiator 1)...1.68 parts by mass

[0423] ・Photopolymerization initiator (initiator 4)...0.63 parts by mass

[0424] ・Alkali-soluble resin (resin A)...0.60 parts by mass

[0425] ・Polymerizable compound (M1)...6.00 parts by mass

[0426] ・Dye (V1)...20.0 parts by mass

[0427] · Epoxy compound (EHPE 3150, manufactured by Daicel Chemical Industries Ltd.) ... 0.66 parts by mass

[0428] · Polymerization inhibitor (p-methoxyphenol)...0.0007 parts by mass

[0429] Surfactant (1 mass % cyclohexanone solution of a compound of the following structure (Mw=14000, the value of % representing the ratio of the repeating unit is mole %)... 2.50 parts by mass

[04...

Embodiment 2~18、 comparative example 1~4

[0434] As described in the following table, the type of pigment dispersion liquid, the type and content of photopolymerization initiator, the type of alkali-soluble resin, the type of dye, and the type of polymerizable compound were respectively changed, except that it was the same as in Example 1. The photosensitive coloring composition was prepared by the method. In addition, the numerical value of content described in the photoinitiator column of the following table|surface is content in the total solid content of a photosensitive coloring composition.

[0435] [Table 1]

[0436]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Volume resistance | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com