Adhesive composition, adhesive composition for polarizing plates, adhesive for polarizing plates, and polarizing plate formed using same

A technology of adhesives and compositions, applied in the direction of non-polymer organic compound adhesives, non-polymer adhesive additives, adhesives, etc., can solve the problems of curing state deviation, etc., and achieve excellent adhesion, good adhesion Excellent adhesion and decolorization resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

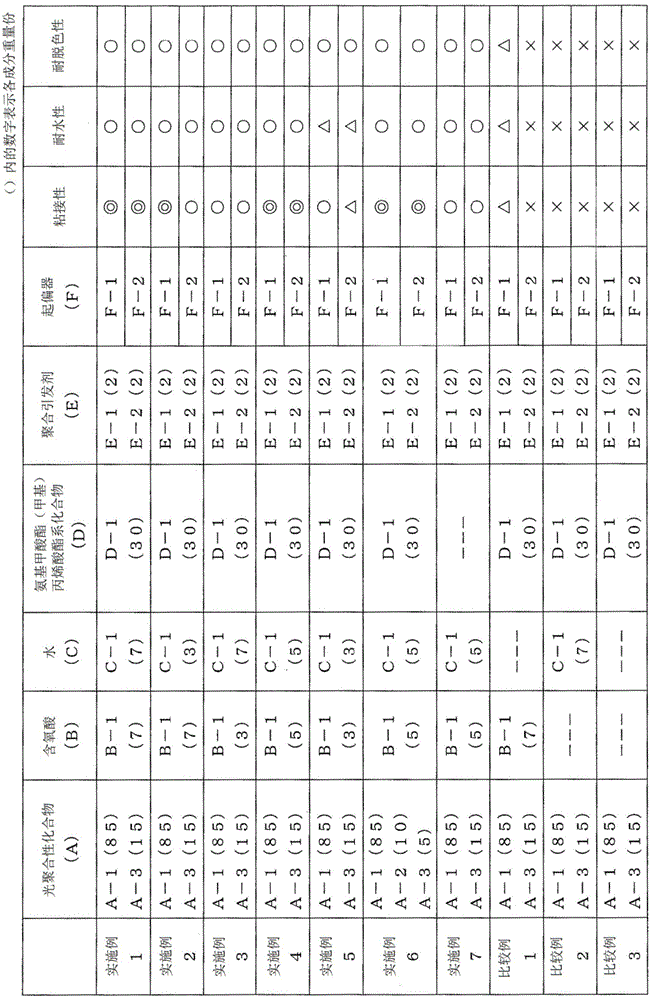

[0155] Although an Example is given below and this invention is demonstrated more concretely, this invention is not limited to the following Example unless the summary is exceeded. In addition, "part" and "%" in an example refer to a basis of weight.

[0156] Prepare the following ingredients.

[0157] [Photopolymerizable compound (A)]

[0158] · (A-1) Dimethacrylamide ("DMAA" manufactured by KJ Chemicals Corporation)

[0159] (A-2) Acryloylmorpholine ("ACMO" manufactured by KJ Chemicals Corporation)

[0160] ・(A-3) Ethylene glycol diacrylate (“FA-222A” manufactured by Hitachi Chemical Co., Ltd.)

[0161] 〔Oxoacid (B)〕

[0162] ・(B-1) Boric acid (manufactured by Wako Pure Chemical Industries, Ltd.)

[0163] [Water (C)]

[0164] ·(C-1) Ion-exchanged water

[0165] [Urethane (meth)acrylate compound (D)]

[0166] ・(D-1) Bifunctional polyether-based urethane acrylate obtained by the following synthesis example

Synthetic example 1

[0168] Add 0.3 g of dibutyltin dilaurate, 0.2 g of 4-methoxyphenol as a polymerization inhibitor, and 166 g of polytetramethylene glycol (molecular weight 650) to a 500 ml reaction vessel equipped with a stirrer, and stir them while The liquid temperature was heated to 40°C.

[0169] 200 g of hydrogenated diphenylmethane diisocyanate was slowly added to the reaction solution, and the temperature was raised to 60° C. over 1 hour. After continuing the reaction at 60°C until the free NCO% was 8.6%, 134 g of 2-hydroxyethyl acrylate was added, and the reaction was continued until the free NCO% was 0.5% or less to obtain a bifunctional polyether-based urethane acrylate (D-1).

[0170] The obtained bifunctional polyether-based urethane acrylate (D-1) had a weight average molecular weight of 3000 and a viscosity of 12000 mPa·s / 60°C.

[0171] [Polymerization initiator (E)]

[0172] ・(E-1) 1-Hydroxycyclohexyl phenyl ketone ("IRGACURE 184" manufactured by BASF Corporation)

[0173] ・...

Embodiment 1

[0175]

[0176]Put 85 parts of dimethylacrylamide (A-1) and 7 parts of boric acid (B-1) into the preparation flask at the same time, heat the liquid temperature to 60°C while stirring them, and continue mixing for 1 hour until the boric acid ( B-1) Completely dissolved. After cooling to room temperature, 15 parts of ethylene glycol diacrylate (A-3), 7 parts of ion-exchanged water (C-1), 30 parts of urethane acrylate (D-1), IRGACURE 184 (E-1) 2 parts and 2 parts of Lucirin TPO (E-2) were mixed, and the adhesive composition for polarizing plates was obtained by mixing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com