Special tool for disassembling socket head cap screw

A hexagonal screw and screw technology, applied in the direction of manufacturing tools, screwdrivers, wrenches, etc., can solve the problems of screw and installation screw machine damage, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0051] A. The material of the main assembly component of the special tool for dismantling the hexagon socket head cap screw described in the specific embodiment 1 is common tool steel;

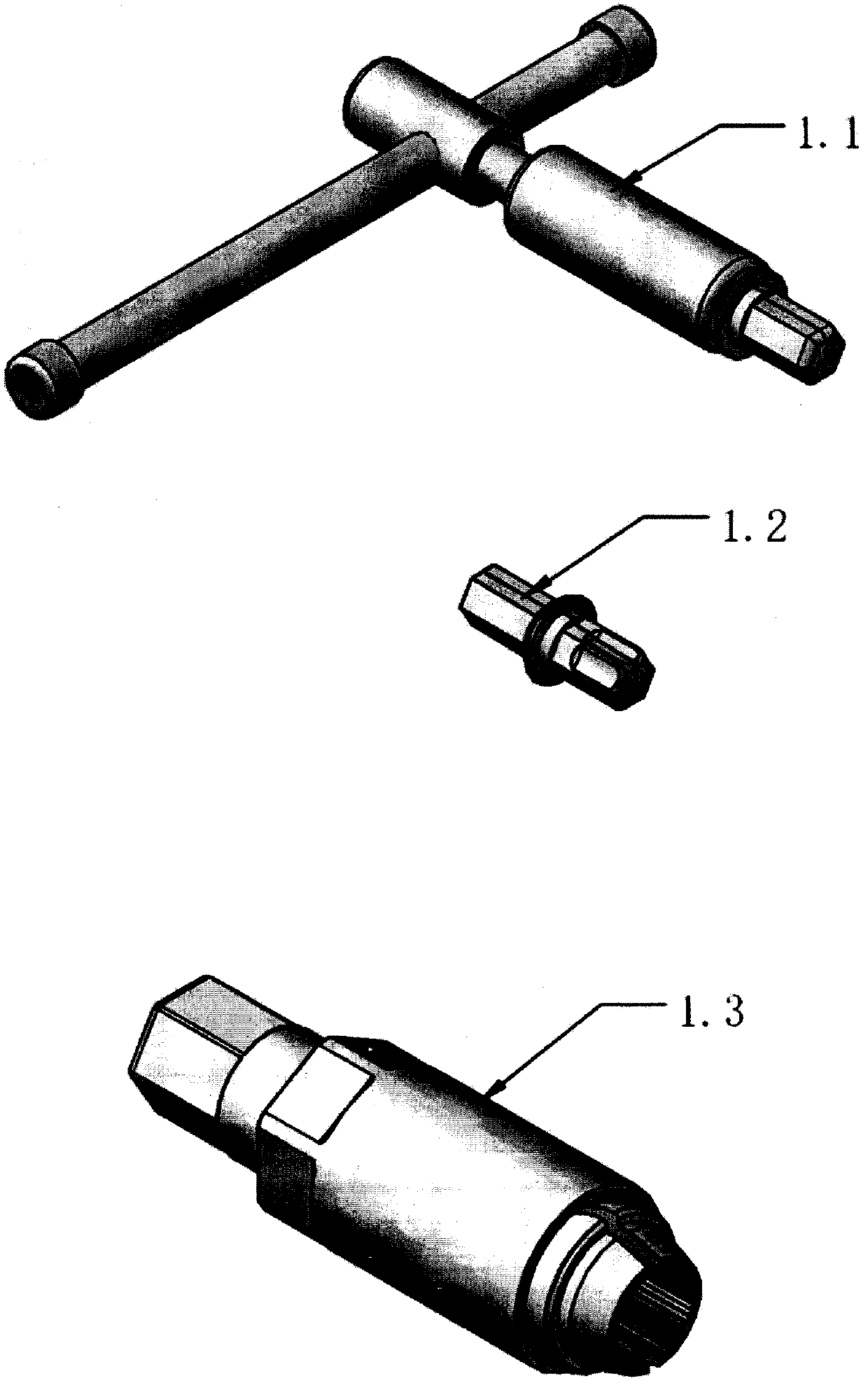

[0052] B. The special tool for dismantling the hexagon socket screw described in the specific embodiment 1 will be made into two tools of the commonly used hexagon socket wrench (1.1) and strong wrench (1.3);

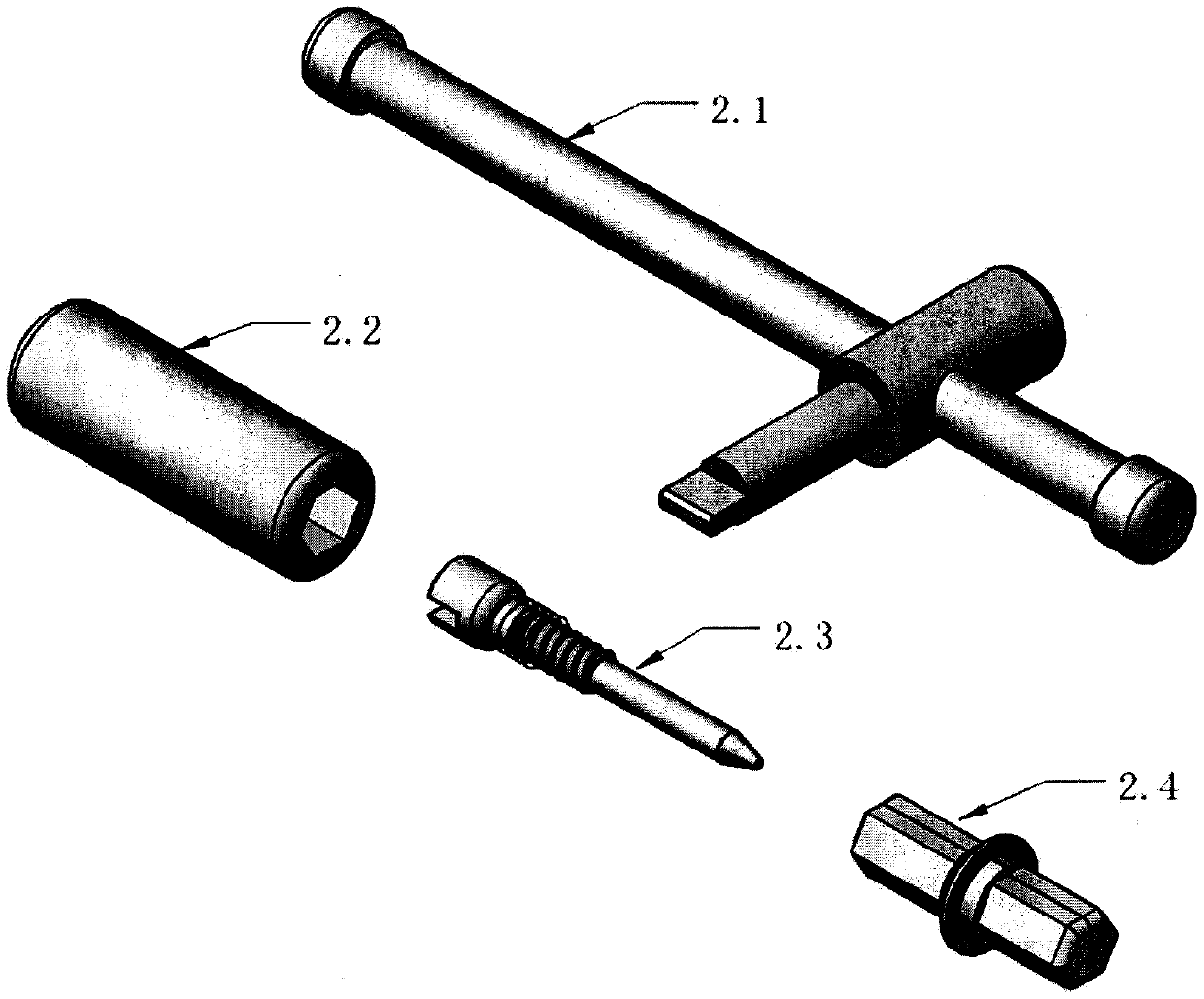

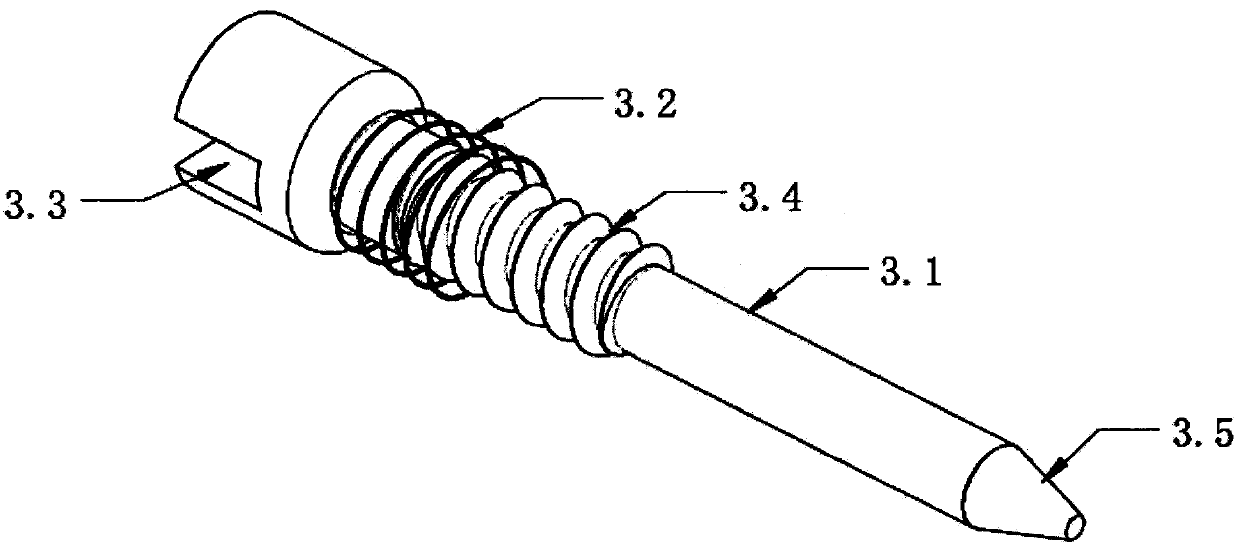

[0053] C. The commonly used hexagonal wrench (1.1) described in the specific embodiment 1 is composed of parts such as an auxiliary fastening wrench (2.1), a wrench connecting sleeve (2.2), a fastening thimble (2.3), and a wrench (2.4). It is suitable for dismantling screws in normal state and relatively strong screws;

[0054] D. The strong wrench (1.3) described in the specific embodiment 1 is made of parts such as a strong sleeve (7.1), a connecting wrench (7.2), a strong bayonet (7.3), a connecting pin (7.4); The wrench (1.1) is used in conjunction with it, and is mainly used for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com