Detachable CFG pile drilling device

A drilling device and detachable technology, applied in the field of detachable CFG pile drilling devices, can solve the problems of troublesome connection of drill pipes, inconvenient use, waste of time, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

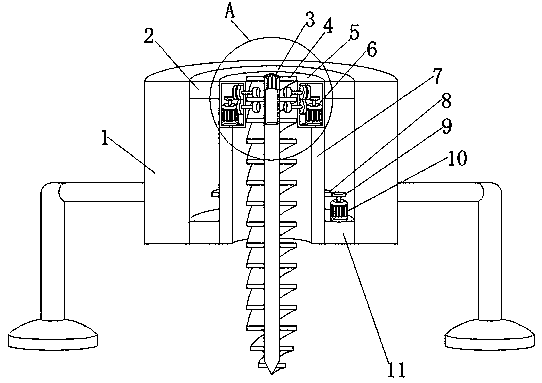

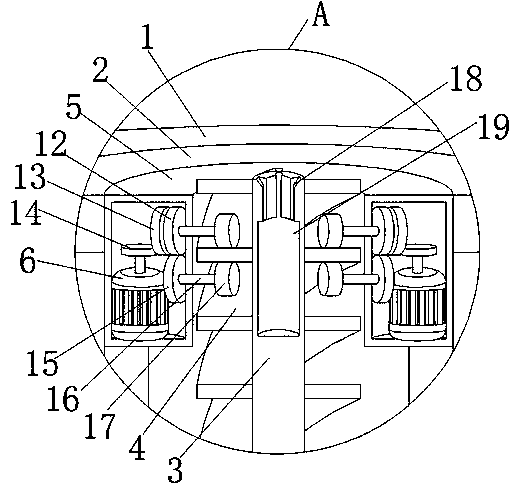

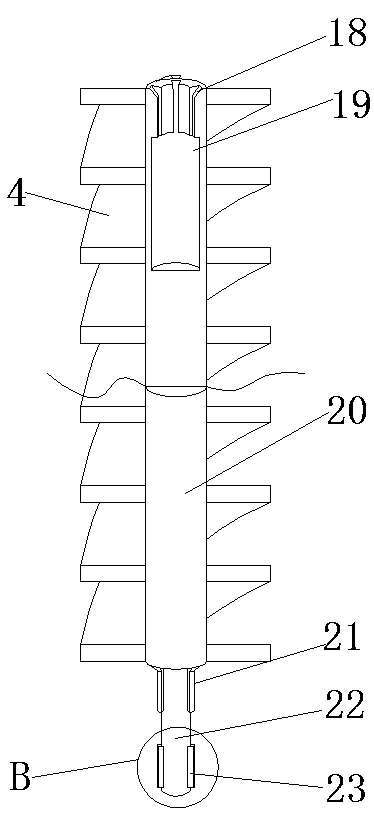

[0028] refer to Figure 1-5 , a detachable CFG pile drilling device, comprising a main body 1, a first drill rod 3 and a second drill rod 20, the middle part of the main body 1 is provided with a first through hole, and the main body 1 is welded with a second through hole at the first through hole A fixed ring 2 and a second fixed ring 11, the middle part of the second fixed ring 11 is rotatably connected with a rotating body 7, the top of the rotating body 7 is welded with a fixed box 5, the inside of the fixed box 5 is provided with a drive mechanism, and the fixed box 5 is ring, the first drill rod 3 is in the middle of the fixed box 5, and the inner walls on both sides of the fixed box 5 are rotatably connected with two rotating shafts 16, and one end of the two rotating shafts 16 is connected with a roller 17 by a key, and the first drill rod 3 and the outer wall of the second drill rod 20 are welded with a helical piece 4, the helical piece 4 is between the two rollers 1...

Embodiment 2

[0037] refer to Image 6 , a detachable CFG pile drilling device. Compared with Embodiment 1, in order to increase the practicability of the device and facilitate the disassembly of the second drill rod 20, the top of the main body 1 is welded with two support columns 26, The tops of the two support columns 26 are welded with the same fixed body 27, and the middle part of the fixed body 27 is provided with an electromagnetic chuck 28. When the drilling is completed and the second drilling rod 20 rises, the second drilling 20 is separated from the roller 17. Start the electromagnetic chuck 28 at the same time, the electromagnetic chuck 28 produces suction, attracts the second drill rod 20, makes the upper body of the second drill rod 20, the block 21 is separated from the draw-in groove 18, the first drill rod 3 cannot drive the second drill rod 20 to rotate, Under the action of the spring 25, the two moving blocks 23 return to their original positions, the fixing rod 22 can le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com