Strengthening method for construction channel on weak bearing layer

A technology for construction passages and bearing layers, applied in soil protection, foundation structure engineering, sheet pile walls, etc., can solve problems such as poor surface bearing capacity of weak bearing layers, subsidence of the weight walking mechanism, difficulty in getting out of mechanical equipment, etc., to achieve load bearing Effects of increased force, prevention of sagging and trapping, and ease of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

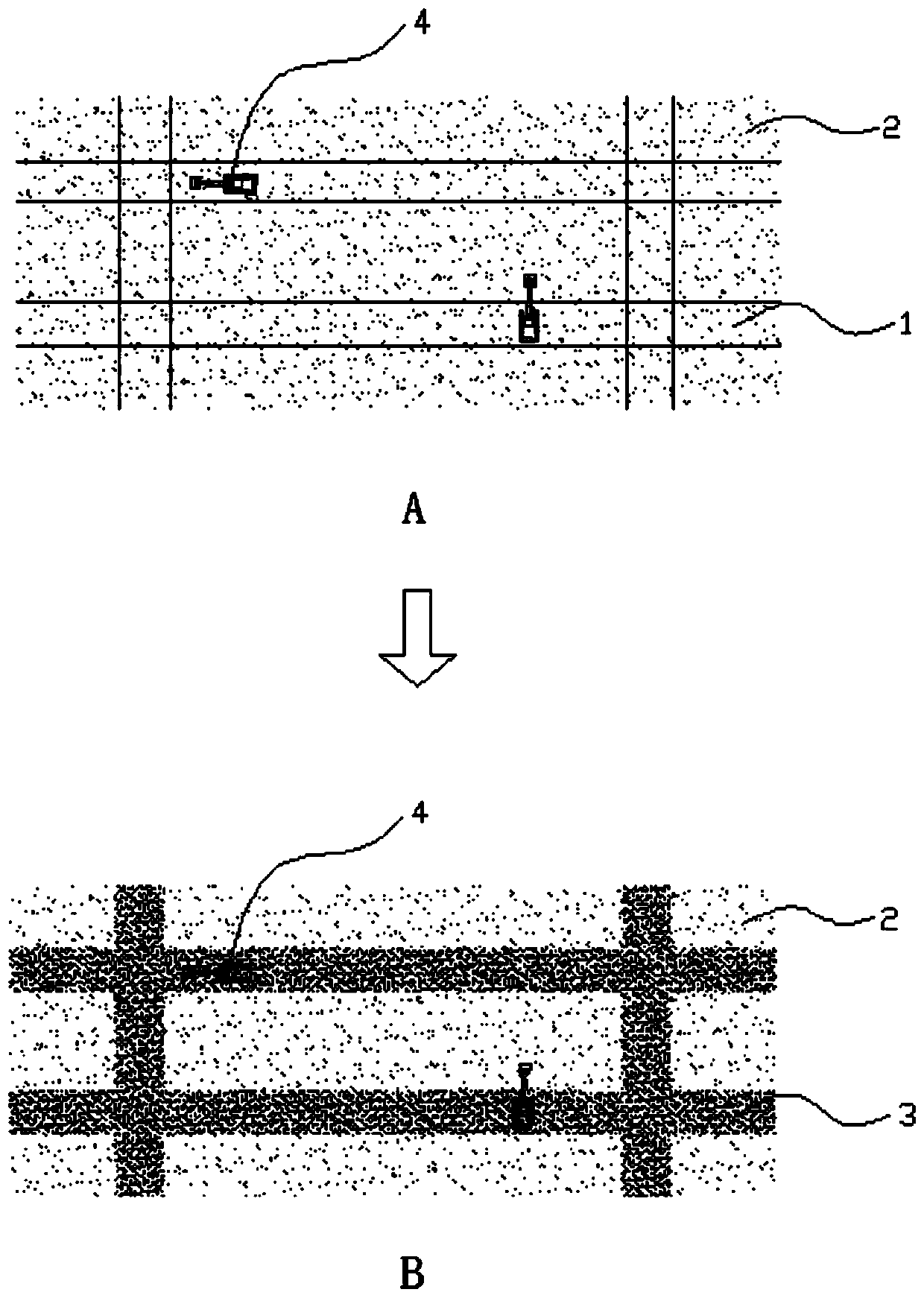

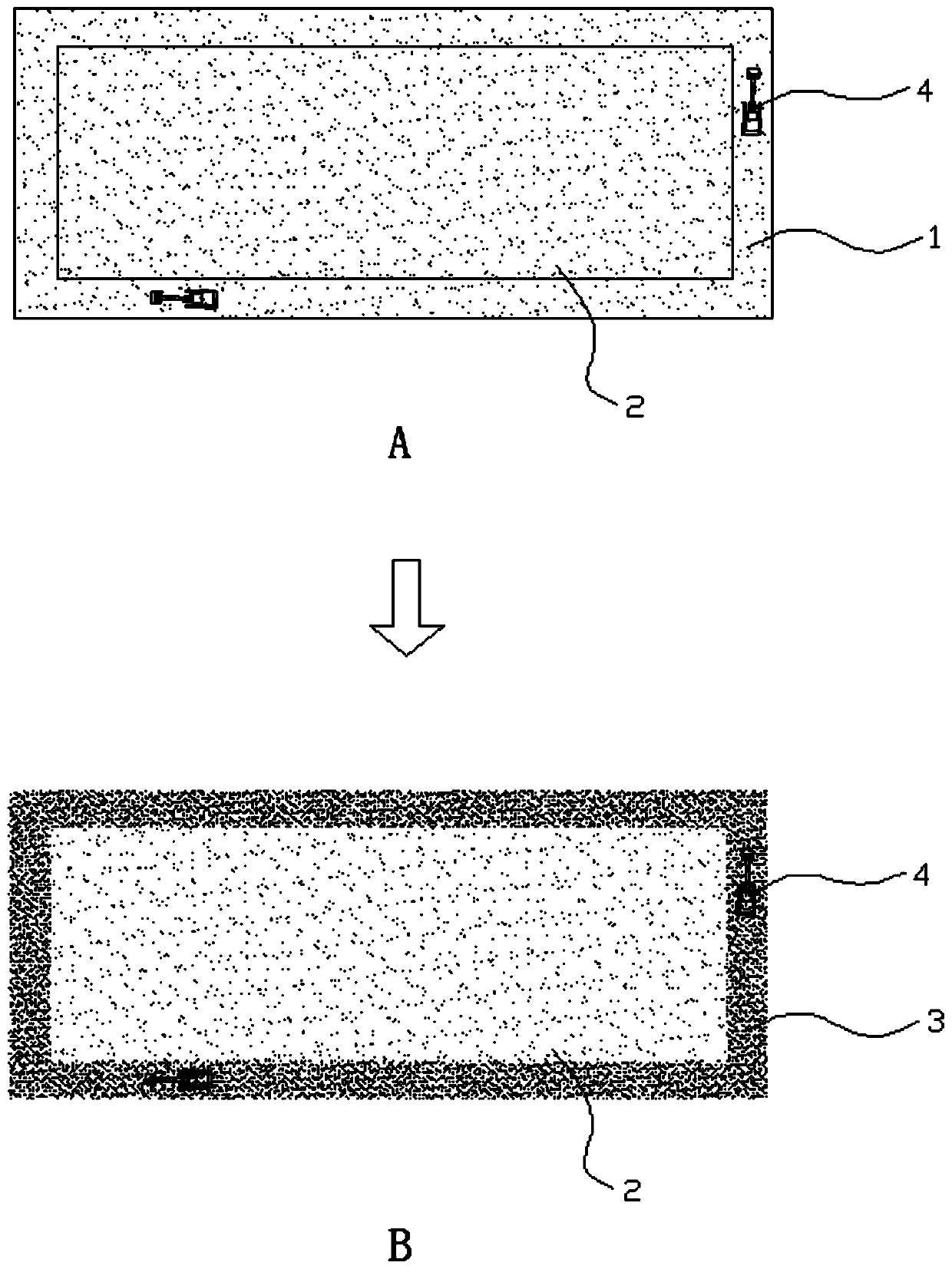

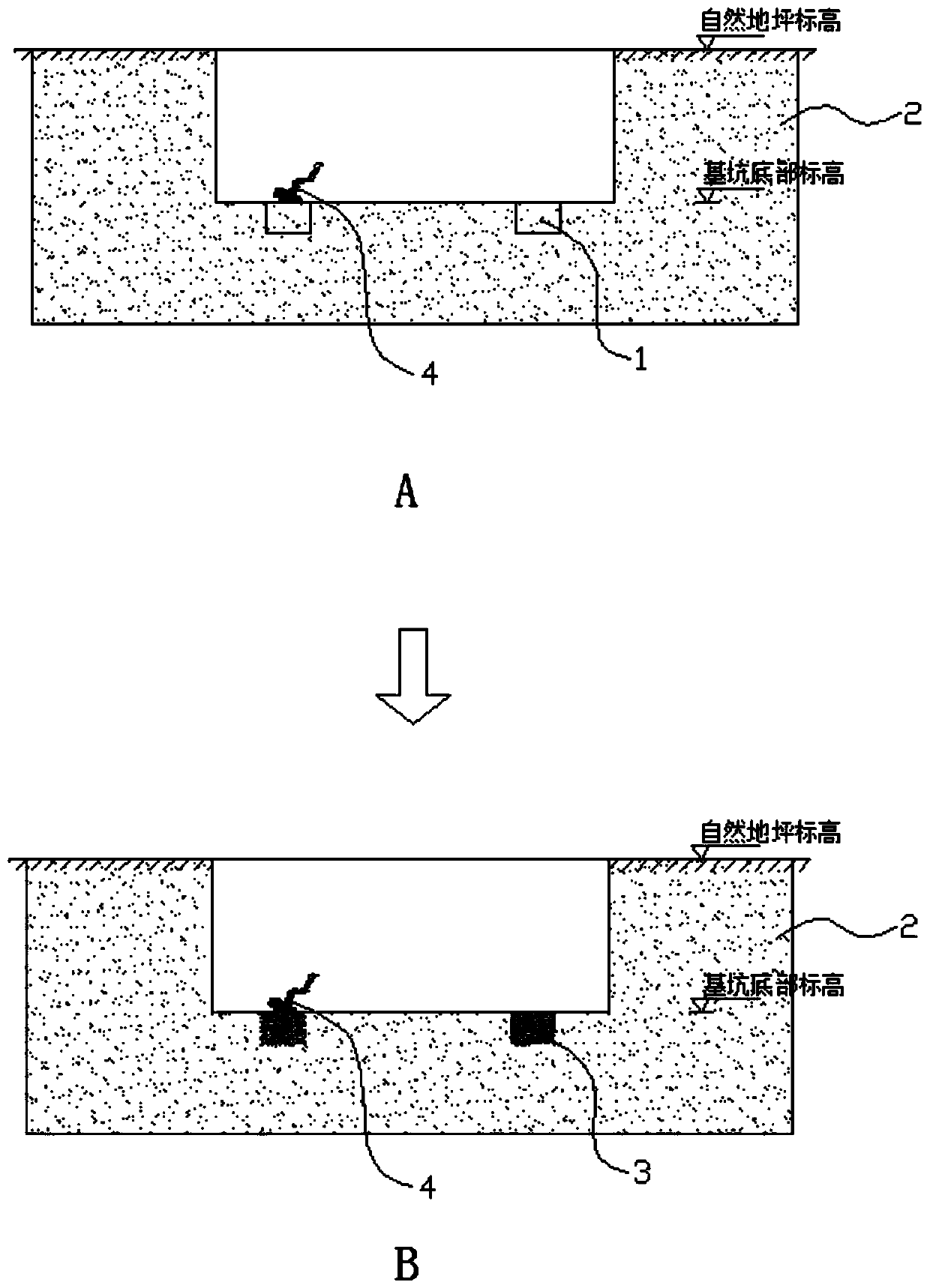

[0035] The strengthening method of the construction channel on the weak bearing layer provided in this embodiment is to fill the construction channel 1 on the ground of the weak bearing layer 2 with filler mixed with adhesive and / or curing agent so that the construction channel 1 forms a continuous reinforcement area, Improve the carrying capacity of the construction channel 1 to the construction machine 4 .

[0036] The strengthening method of the construction channel on the weak bearing layer provided in this embodiment uses the rotary jet drill to fill the weak bearing layer 2 of the construction channel 1 on the construction site with filler to form a reinforcement area 3 and carry out the soil mass of the construction channel 1 with the high-pressure rotary jetting method. strengthen. The reinforcement method includes the following steps:

[0037] 1) Preparatory steps: level the construction site, determine the area of the construction passage 1 according to the site c...

Embodiment 2

[0059] The same parts as those in Embodiment 1 are given the same reference numerals, and the same text descriptions are omitted.

[0060] Compared with Example 1, the strengthening method of foundation pit protection of this example uses the mixing method to fill the weak bearing layer 2 of the construction channel 1 with fillers to strengthen the soil and form a reinforced area 3 . The reinforcement method includes the following steps:

[0061] 1) Preparatory steps: level the construction site, determine the area of the construction passage 1 according to the site construction specifications, and further determine the reinforcement form of the construction passage 1 and the distribution of the drill holes in the reinforcement area 3. Construction channel 1 includes the passage paths of construction machinery around the construction site (such as figure 1 shown in middle A), the passage path of construction machinery in the middle of the construction site (such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com