Anti-silting system and method for subgrade geotextile compartment covering subgrade of immersed tunnel tunnel

A technology of immersed tube tunnel and geotextile, which is applied in infrastructure engineering, excavator/dredging machine operation methods, artificial islands, etc. It can solve problems such as cracking of pipe sections, failure of immersed pipe joints to implant, and changes in seawater bulk density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

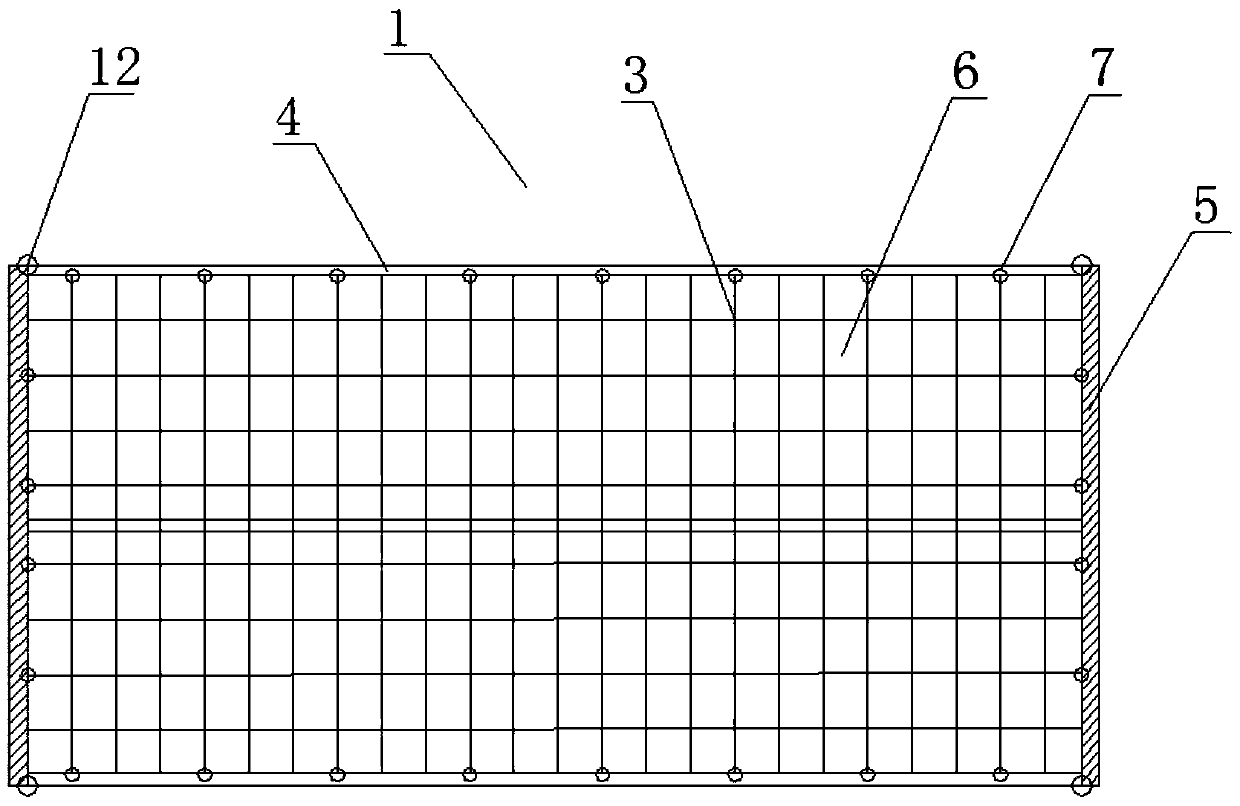

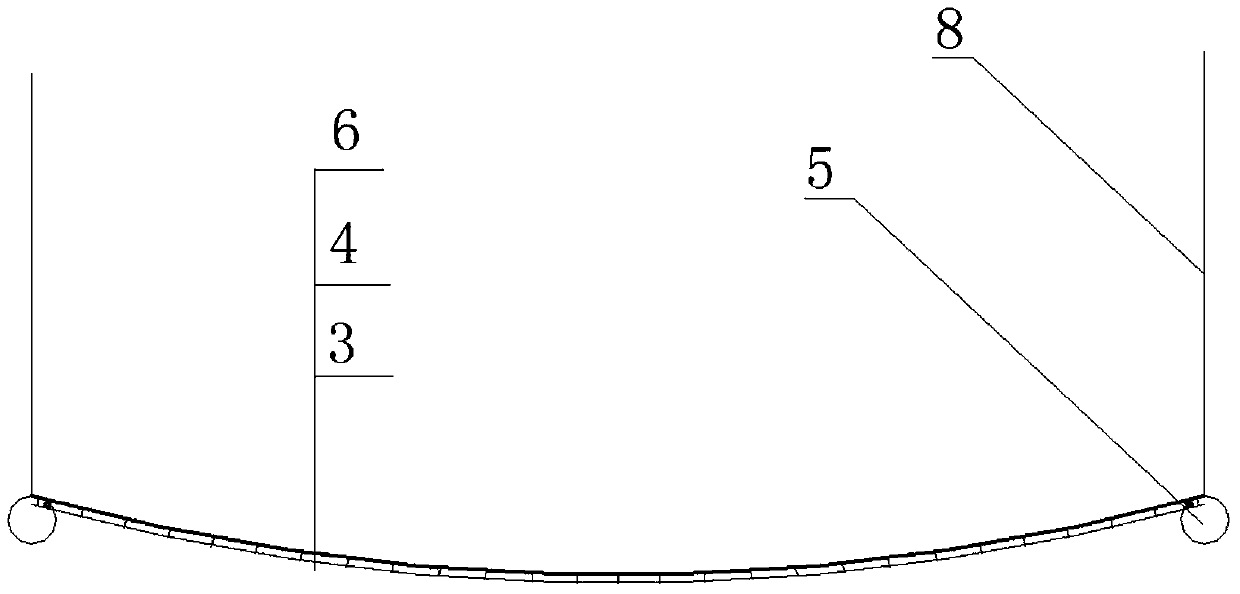

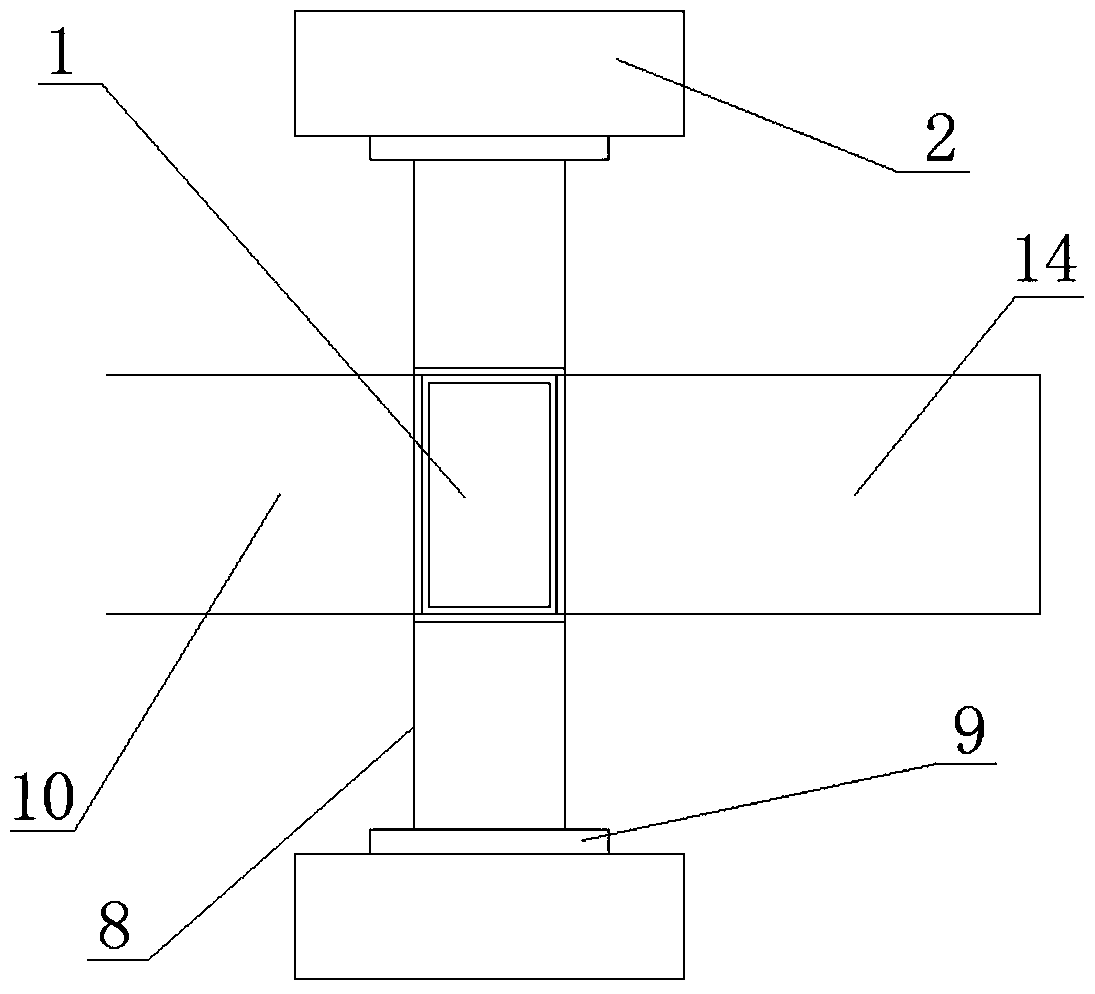

[0021] Such as Figure 1 to Figure 3 As described above, the subgrade geotextile compartment cover anti-silting system of the immersed tube tunnel of the present invention comprises a compartment geotextile dredging device 1 and two laying ships 2, a slide plate 9 is arranged at one end of the laying ship, and the compartment geotextile The dredging device 1 has a size of 26m×42m. The compartment geotextile dredging device 1 consists of a compartment 3, a steel wire rope 4, a steel pipe 5 and a geotextile 6. Multiple compartment geotextiles with upward hatches (each compartment 2*2m), the compartment geotextile is composed of 2m*2m compartments, the overall size is 26m×42m, providing a device for storing silt and covering the foundation bed, rigid support steel pipes 5 are installed at both ends of the geotextile 6, and the length of the steel pipe is 26m The two steel pipes 5 are connected by 3 steel wire ropes 4 with a length of 42 meters. A geotextile 6 is arranged above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com