Construction device and construction method for coastal sand foundation pit slope

The technology of a construction device and construction method, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems such as the steel wire mesh and the slope surface are not easy to fix, the steel mesh is warped, and the vegetation is destroyed, so as to achieve a simple construction method and reduce the burden , to avoid the effect of wasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

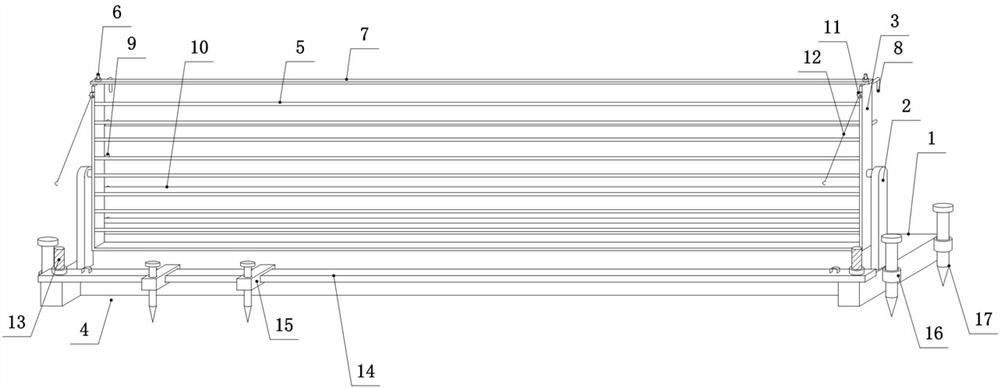

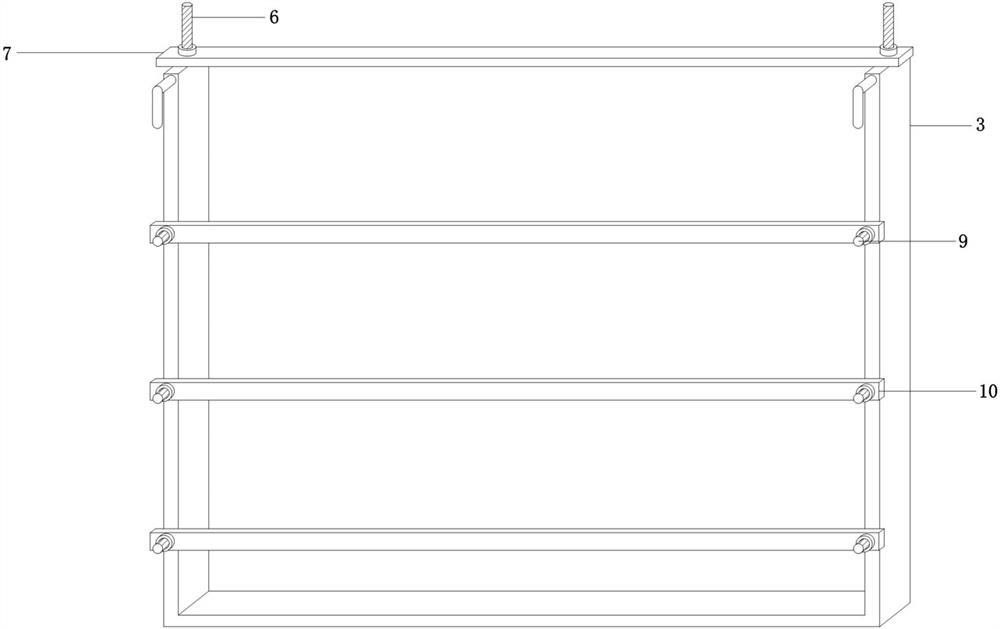

[0033] Example: see figure 1 , figure 2 and Figure 4 , a construction device for the side slope of a sandy foundation pit near the sea, including a first base 1, a U-shaped frame 3 and a positioning drill 17, the front end of the first base 1 is dug with a concave hole 4, and both sides of the concave hole 4 are provided with The third stud 13 , a third pressing plate 4 is sleeved on the third stud 13 and is fixed by a nut. At least one displacement frame 15 is slidably connected to the third pressing plate 4 , and a front end of the displacement frame 15 is inserted with a Positioning drill 17; the rear end of the first base 1 is provided with a bracket 2, and there are two brackets 2, and a U-shaped frame 3 is rotatably connected between the two brackets 2, and the top of the U-shaped frame 3 is provided with a first pressure plate 7. The front end surface of the U-shaped frame 3 is provided with a limiting strip 5 , and the rear end surface of the U-shaped frame 3 is pr...

Embodiment 2

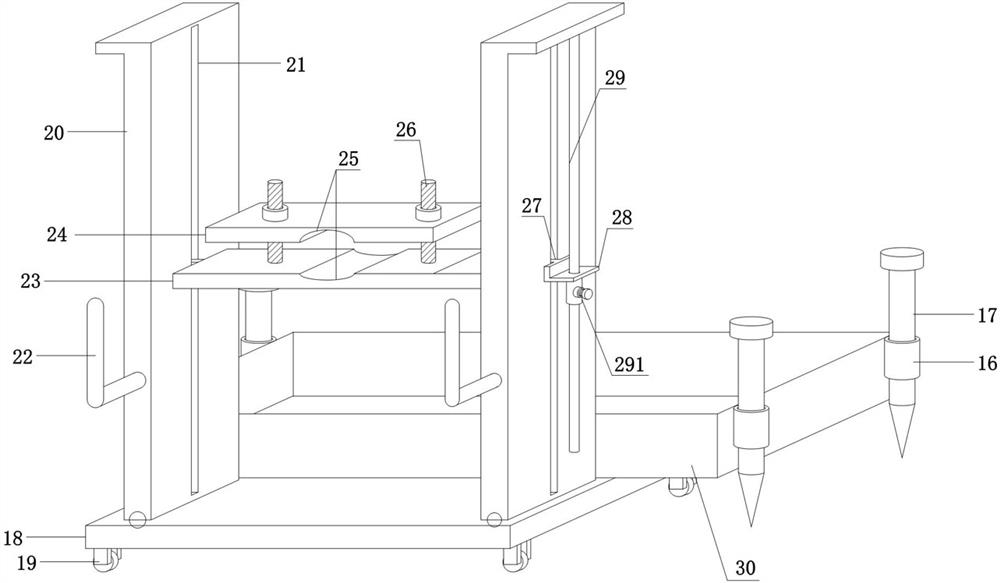

[0041] Example 2: see image 3 , a construction method of a side slope construction device for a foundation pit in a coastal sandy land, comprising the following steps:

[0042]S1: Place the auxiliary device for the construction of the foundation pit slope at the upper edge of the slope, and set the required displacement frame 15 on the third pressing plate 14 according to the width of the steel mesh, and the steel mesh is laid from top to bottom;

[0043] S2: Lay the steel mesh on the uppermost part of the slope, insert the positioning drill 17 on the inner side of the upper edge of the steel mesh, make the positioning drill 17 pass through the front of the displacement frame 15, and use a hammer to insert the positioning drill into the soil ;

[0044] S3: After the top reinforcement mesh is fixed, the lower reinforcement mesh can be laid. When laying, the lap joint method is adopted, and a hook is set on the top of the lower reinforcement mesh, and the bottom of the upper r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com