Ultrasonic plastic welding machine

A plastic welding and ultrasonic technology, applied in the field of ultrasonic plastic welding machines, can solve the problems of high production cost, high energy consumption and high welding head temperature, and achieve the effects of convenient operation, energy saving and scalding prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

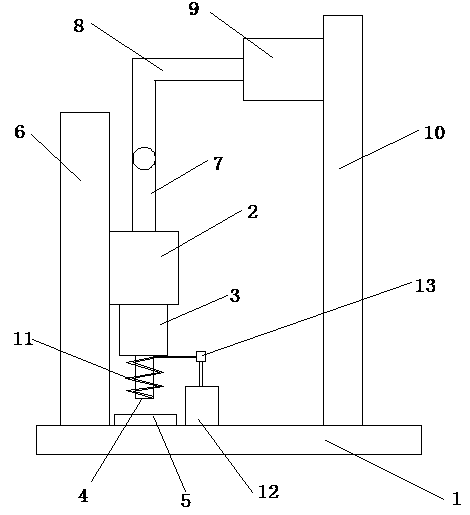

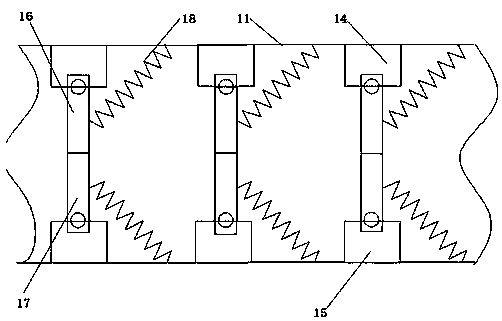

[0015] Such as figure 1 The ultrasonic plastic welding machine shown includes a base 1, a support body 2 is arranged above the base 1, and an ultrasonic generator 3 is connected to the lower end of the support body 2. 1. A station plate 5 is arranged above the base 5, and the station plate 5 is used to place workpieces to be welded. The support body 2 is slidably installed on the first vertical shaft 6, the first vertical shaft 6 is arranged on the left end of the base 1, and a slide rail (not shown in the figure) is installed on the right side wall of the first vertical shaft 6, and the support body 2 slides Slide up and down on the rail.

[0016] The upper end of the support body 2 is hinged with a connecting rod 7, the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com