Covering method of bottle caps

A technology for bottle caps and wine bottles, which is applied to bottle/container caps, capping containers tightly with caps, and safety/control of capping machines. , to achieve the effect of no error when wearing the bottle cap, reducing the time of wearing the cap, and improving the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

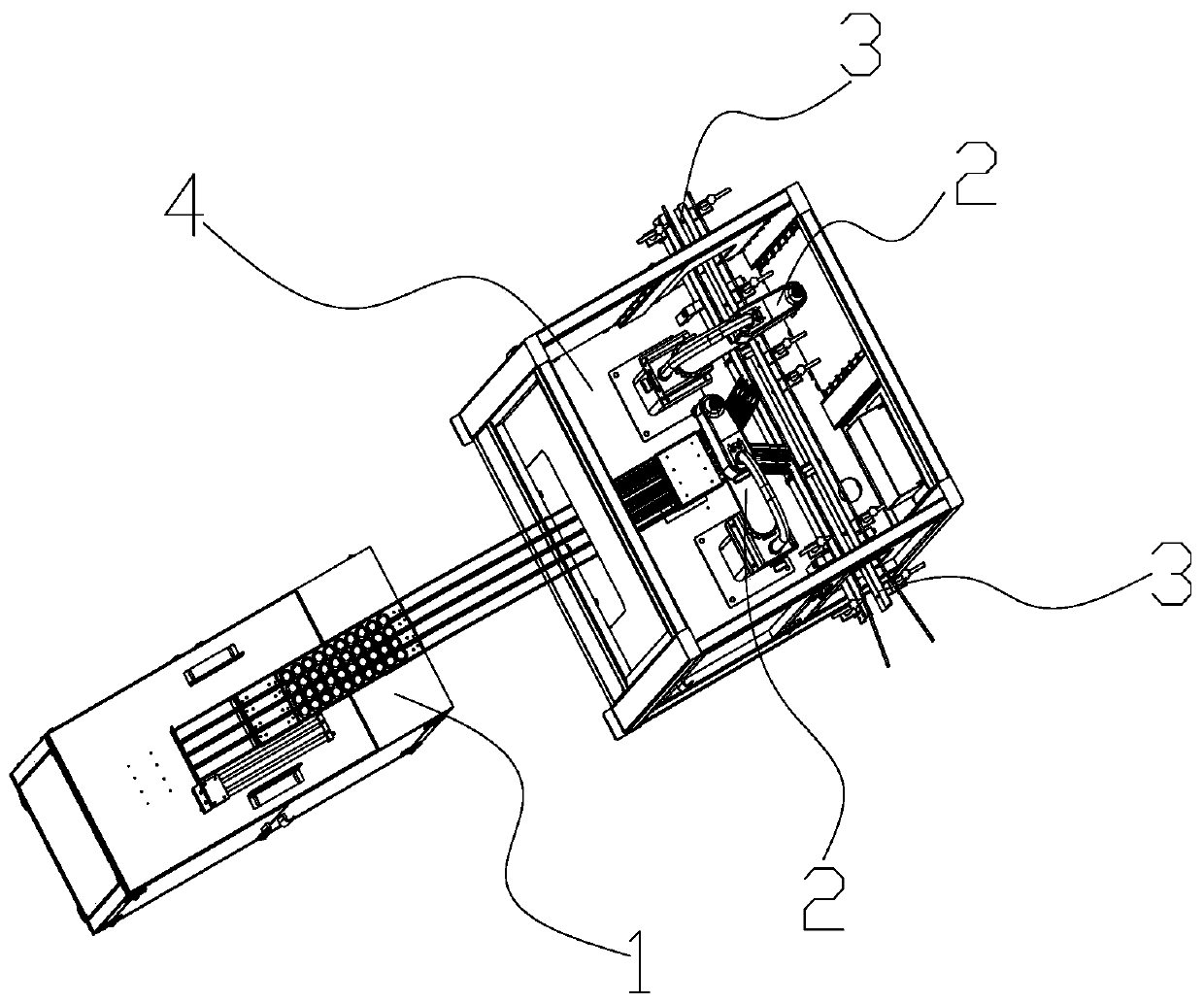

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

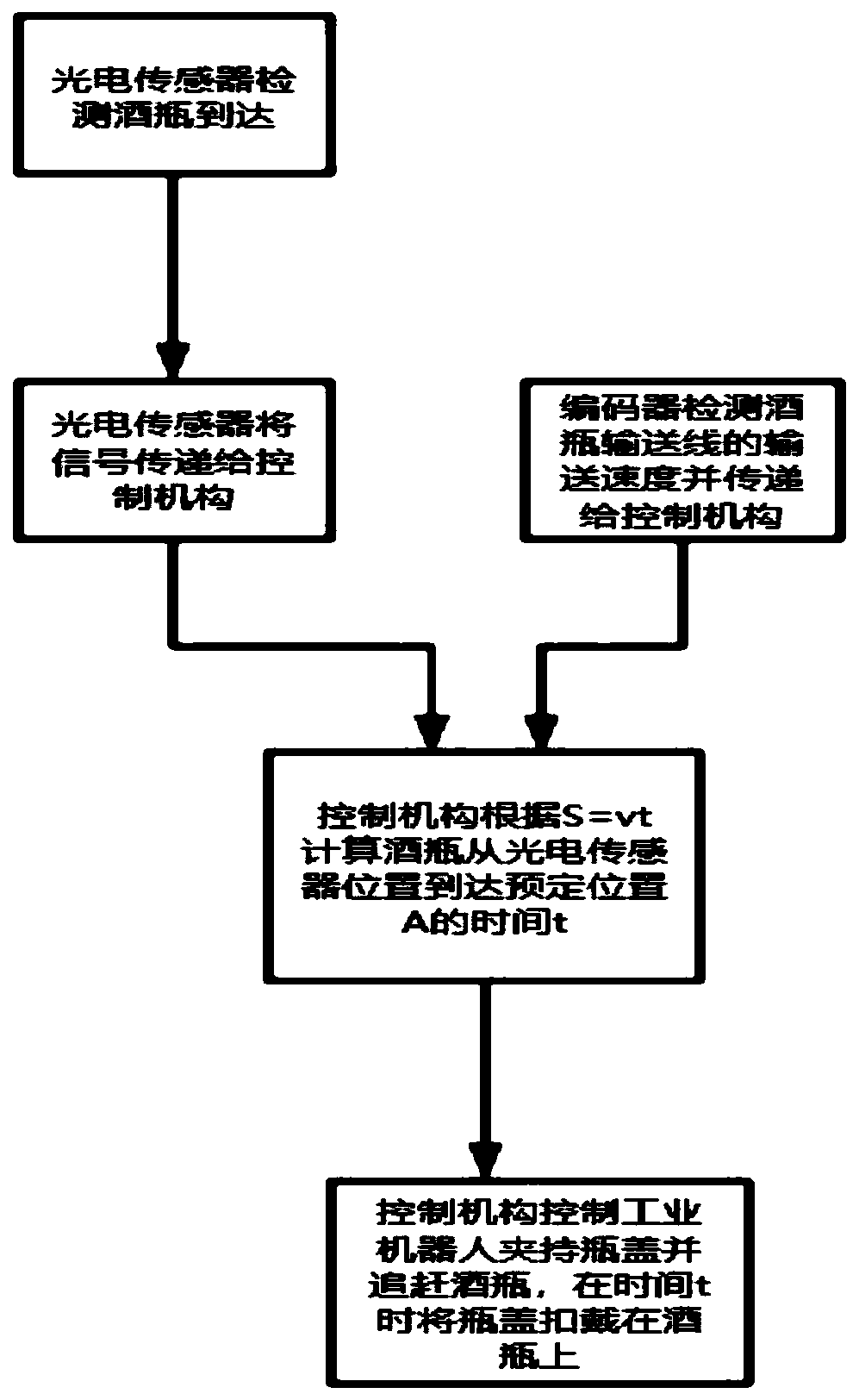

[0020] A method for wearing a bottle cap, comprising the steps of:

[0021] S1. The wine bottle is transported forward along the bottle conveying line. When a wine bottle passes through the position of the photoelectric sensor on the bottle conveying line, the photoelectric sensor changes the signal and transmits the signal to the control mechanism; the encoder detects the wine bottle The conveying speed v of the conveying line is transmitted to the control mechanism.

[0022] S2. After the control mechanism receives the photoelectric sensor signal and the encoder signal, it calculates the time t for the wine bottle from the photoelectric sensor position to the next predetermined position A by S=v*t, t is the time t for the wine bottle to be transported from the photoelectric sensor to the next The time at which location A is scheduled;

[0023] S3. The con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap