Mechanical arm type sleeper crack detection system

A technology for crack detection and sleepers, applied in the field of sleeper production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

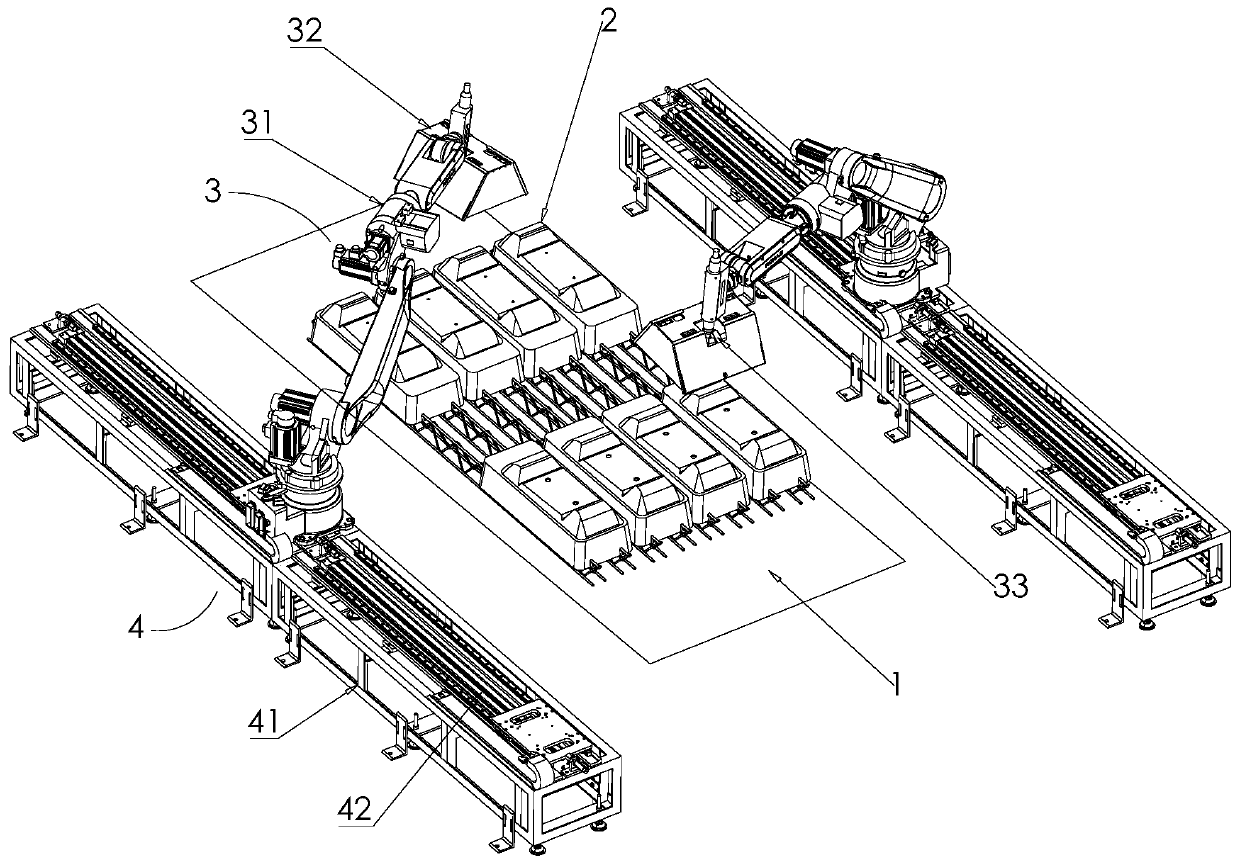

[0020] A mechanical arm type sleeper crack detection system, such as figure 1 shown, including:

[0021] Conveying device 1, used for conveying the sleeper 2 to be detected;

[0022] The detection robot 3 includes a six-axis robot hand 31, the end of the six-axis robot hand 31 is provided with a mounting frame 32, and an industrial 3D camera 33 is arranged in the mounting frame 32, and the industrial 3D camera 33 is connected to a computer (not shown in the figure), six The axis manipulator 31 moves through multiple degrees of freedom, drives the industrial 3D camera 33 to the front and side of the sleeper 2, takes 3D images of the front and side of the sleeper 2, and transmits the captured 3D images to the computer for crack detection;

[0023] The ground rail 4 includes a fixed platform 41, and a linear m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com